ANGLE ROLL MODELS

- Motorized Angle Rolls

- 1.18” ~ 2.36” Top shaft diameters

- Up to 3” SCH 40 Pipe Bending Capacity

- Hydraulic Angle Rolls

- 1.57” ~ 7.08” Top shaft diameters

- Up to 8” SCH 40 Pipe Bending Capacity

- Hydraulic Angle Rolls

- 9.44” ~ 14.17” Top shaft diameters

- Up to 16” SCH 40 Pipe Bending Capacity

A-ECO SERIES

- Motorized Angle Rolls

- 1.18” ~ 2.36” Top shaft diameters

- Up to 3” SCH 40 Pipe Bending Capacity

The A-ECO Series motorized angle rolls are designed for bending small parts with low operation cost. It is also designed for ease of use and to take up only minimal floor space. This machine is well suited for auto body and repair, 4×4 parts, HVAC, plumbing, artists and many other businesses needing to create small, precision parts.

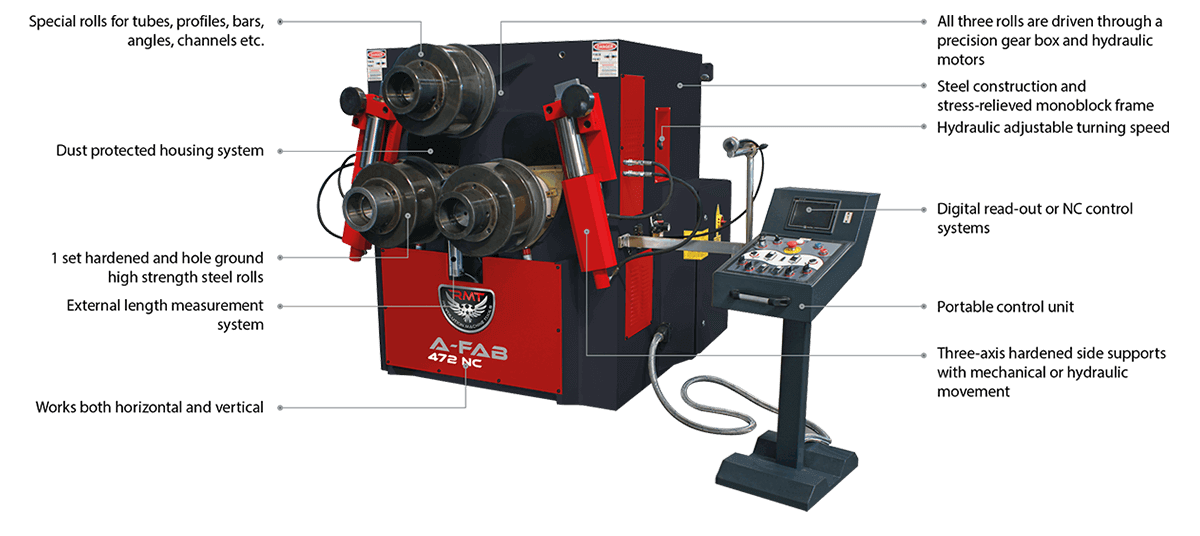

A-FAB SERIES

- Hydraulic Angle Rolls

- 1.57” ~ 7.08” Top shaft diameters

- Up to 8” SCH 40 Pipe Bending Capacity

A-FAB Series hydraulic angle rolls are designed to be the workhorse of our angle roll line. They offer fantastic accuracy and strength as well as cost effective production. This is the model for those who work with a variety of sizes, strengths, and materials.

A-GIANT SERIES

- Hydraulic Angle Rolls

- 9.44” ~ 14.17” Top shaft diameters

- Up to 16” SCH 40 Pipe Bending Capacity

RMT offers the latest technology in “large format” profile bending solutions for your Big Application needs. We specifically developed these systems for the production of ships, bridges, pipe lines, I beams, H beams, towers, high-rise and skyscraper construction, and many other giant applications.

ANGLE ROLLS FEATURES

BUILT TO LAST

The foundation of all RMT Angle Rolls is a solid, industrial strength frame precisely formed and precision welded made from mill-certified, high-yield steel. As a result, RMT Angle Rolls perform accurately and reliably year after year. We’re so confident in our frames that we offer a 10-year warranty with our standard machines. The inner workings are heat treated and induction hardened to provide long life and consistent repeatability in forming parts.

BEND EFFICIENTLY

RMT machines are designed with state-of-the-art technologies that provide unparalleled accuracy and precision. This is the result of our world-class Research and Development departments that has been constantly perfecting our machines for decades, allowing us to consistently outperform our competitors’ machines year after year.

BEND ACCURATELY

If it takes you three times as long to fix your parts as it did to create them, you have the wrong machine. Even a half decent machine can bend a part, but it takes a quality machine to be able to bend reliably and repeatedly without having to take further time and effort to “fix” your parts. RMT angle rolls are engineered to exact specifications to provide real value to your operation.

BEAM BENDING

If only bending I beams was as easy as Superman makes it look. It isn’t. However, with RMT angle rolls you will have the ability to accurately and easily bend I beams, H beams, and just about any other structural steel shape. Our engineers have really put time and effort into creating the right solution for structural steel.