Picking The Perfect Press Brake Accessories

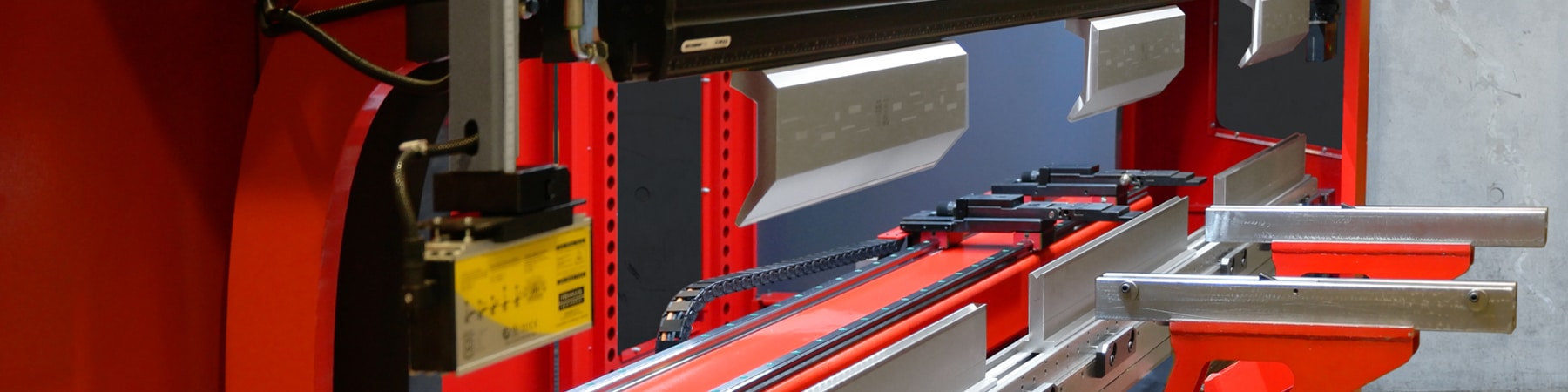

You’re about to purchase the finest press brake on the market for your specific projects. It has the right length for your longest workpieces and more than enough tonnage for your thickest and hardest material. All you need is to sign the paperwork, and you are all ready to go, right?

What Does Crowning Mean in Metal Fabrication?

In metal fabrication, precision is everything. Whether forming sheet metal on a press brake, rolling plate into a cylinder, or bending beams and structural sections, fabricators constantly battle the physical realities of material strength, machine rigidity, and geometry. One of the most common and challenging phenomena that occurs during these operations is deflection—the natural bending or sagging of machines and tools under load.

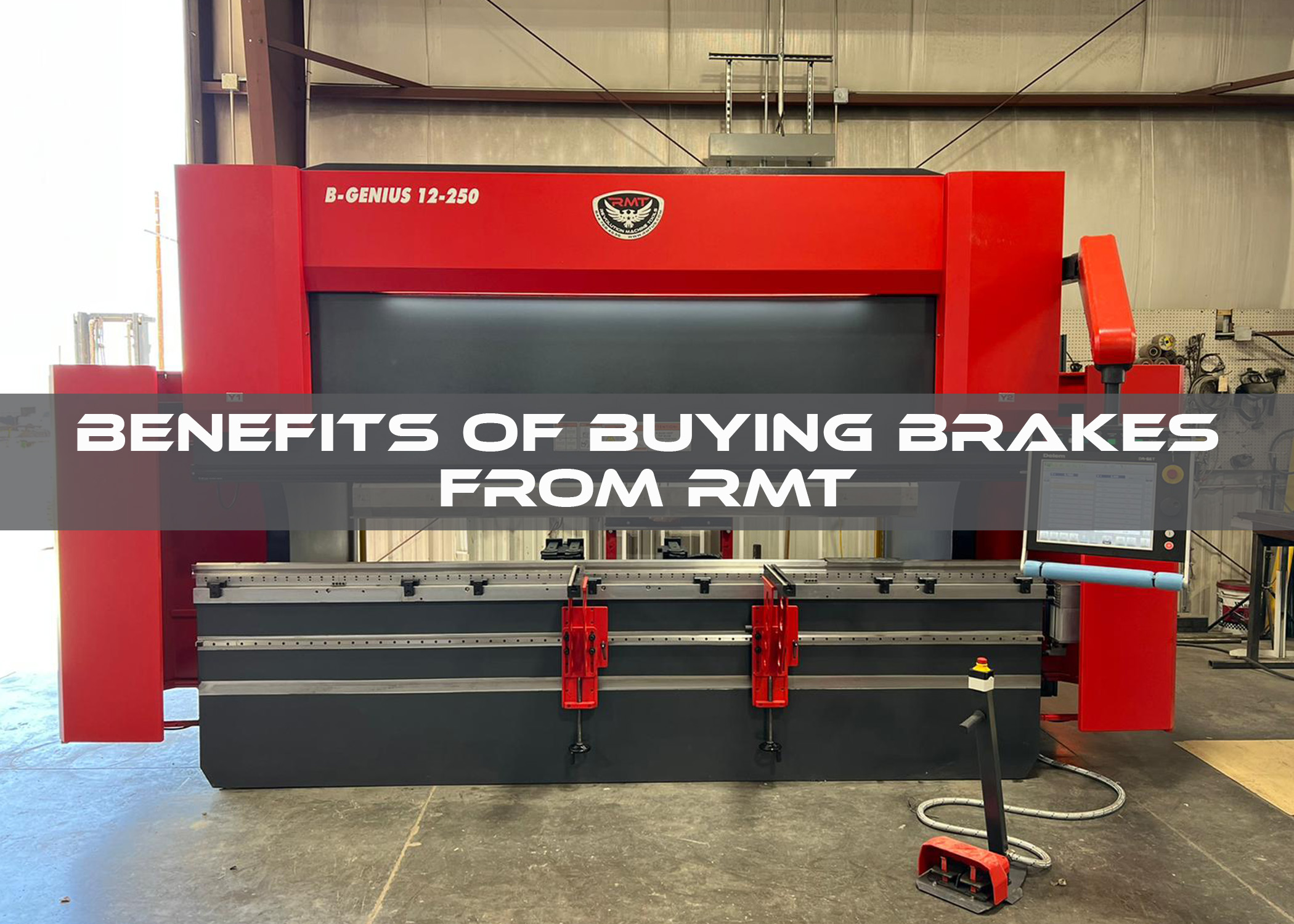

Benefits of Buying Brakes from RMT

Need a new—and high quality—press brake for your metal fabrication operation? Choose your equipment provider carefully. When it comes to bending and shaping metal sheets and plates, a press brake is an essential machine that can make or break your production quality. In the world of metal bending, precision, reliability, and efficiency are key.