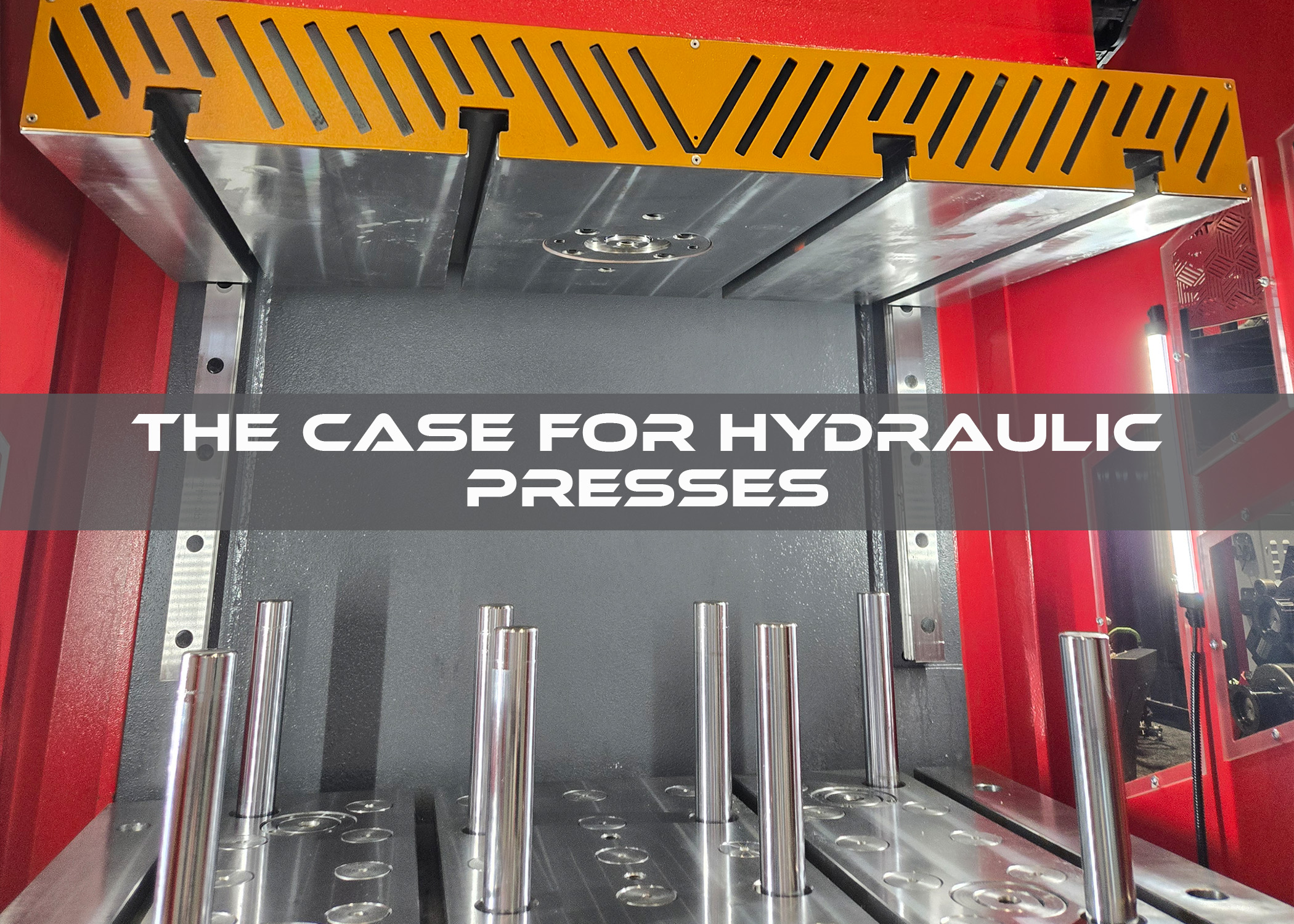

The Case for Hydraulic Presses

Metal fabrication is an industry built on precision, power, and efficiency. From shaping sheet metal to punching holes and forming custom parts, fabrication requires tools that can handle demanding tasks while maintaining consistent results. Among the most versatile and valuable pieces of equipment in any metal fabrication shop is the hydraulic press. Unlike classic mechanical presses, which rely on flywheels and crank systems, hydraulic presses operate using fluid pressure to generate immense force. This difference gives hydraulic presses unique advantages that can significantly improve productivity, safety, and overall business profitability.

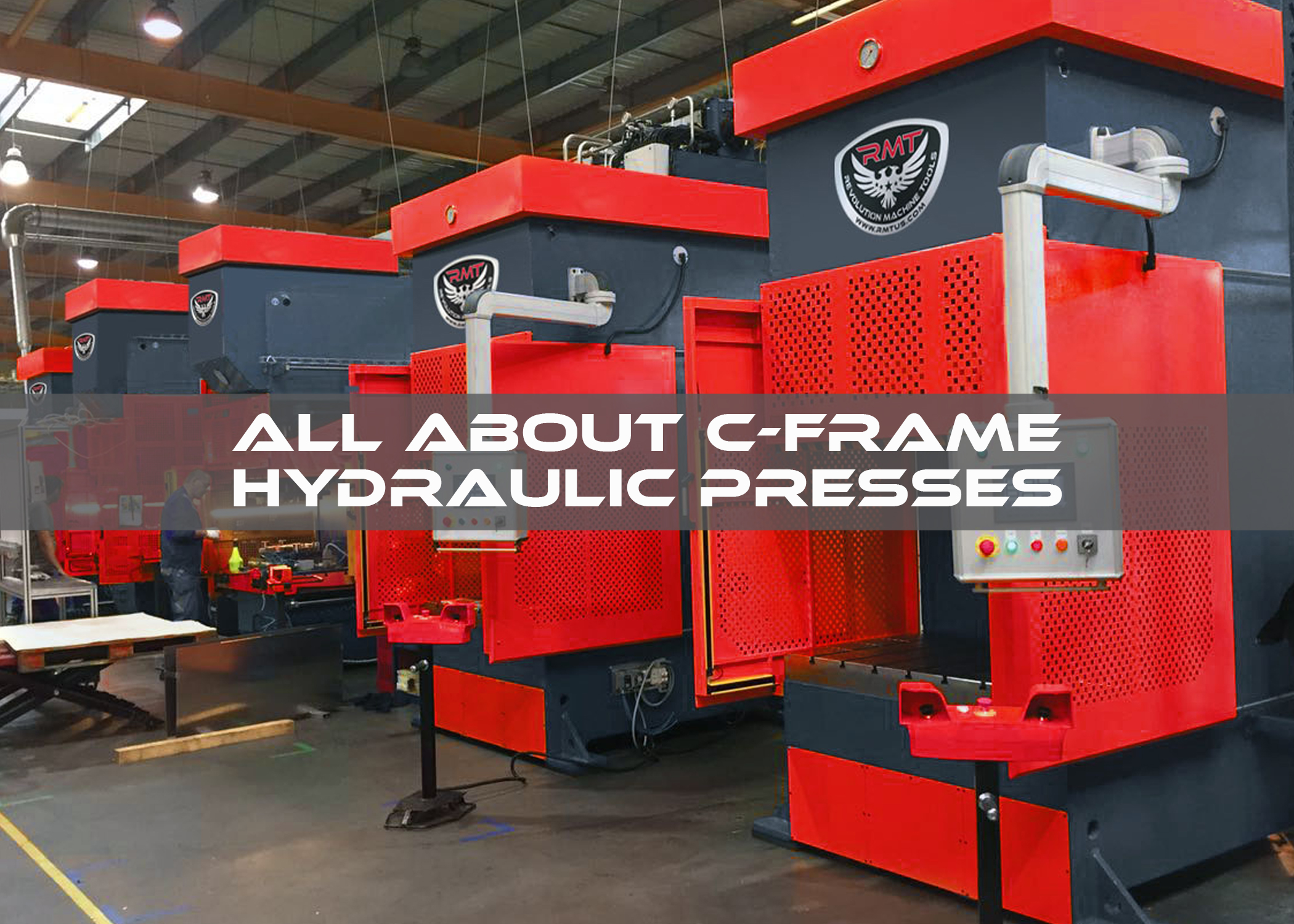

All About C-Frame Hydraulic Presses

A C-frame hydraulic press is a machine that uses hydraulic force to apply pressure to a workpiece. It is named for its “C” shaped frame, which allows for a clear open space on three sides of the work area, making it easier to load and unload materials. The press works by utilizing hydraulic cylinders, which are powered by high-pressure fluid, to exert force on the material. This enables the machine to perform tasks such as stamping, forming, punching, bending, and even assembling parts.

Impressive Hydraulic Presses from RMT

When it comes to fabrication presses—machines used for applying great force against a metallic workpiece—they’ve been around for a good 500 years, though the printing press appeared on the scene half a century earlier, and other pressing devices go back much further in history. It was the need to readily mint coins in the first years of the 1500s that influenced the application of the earlier developed technique of the screw press to form pieces of metal.