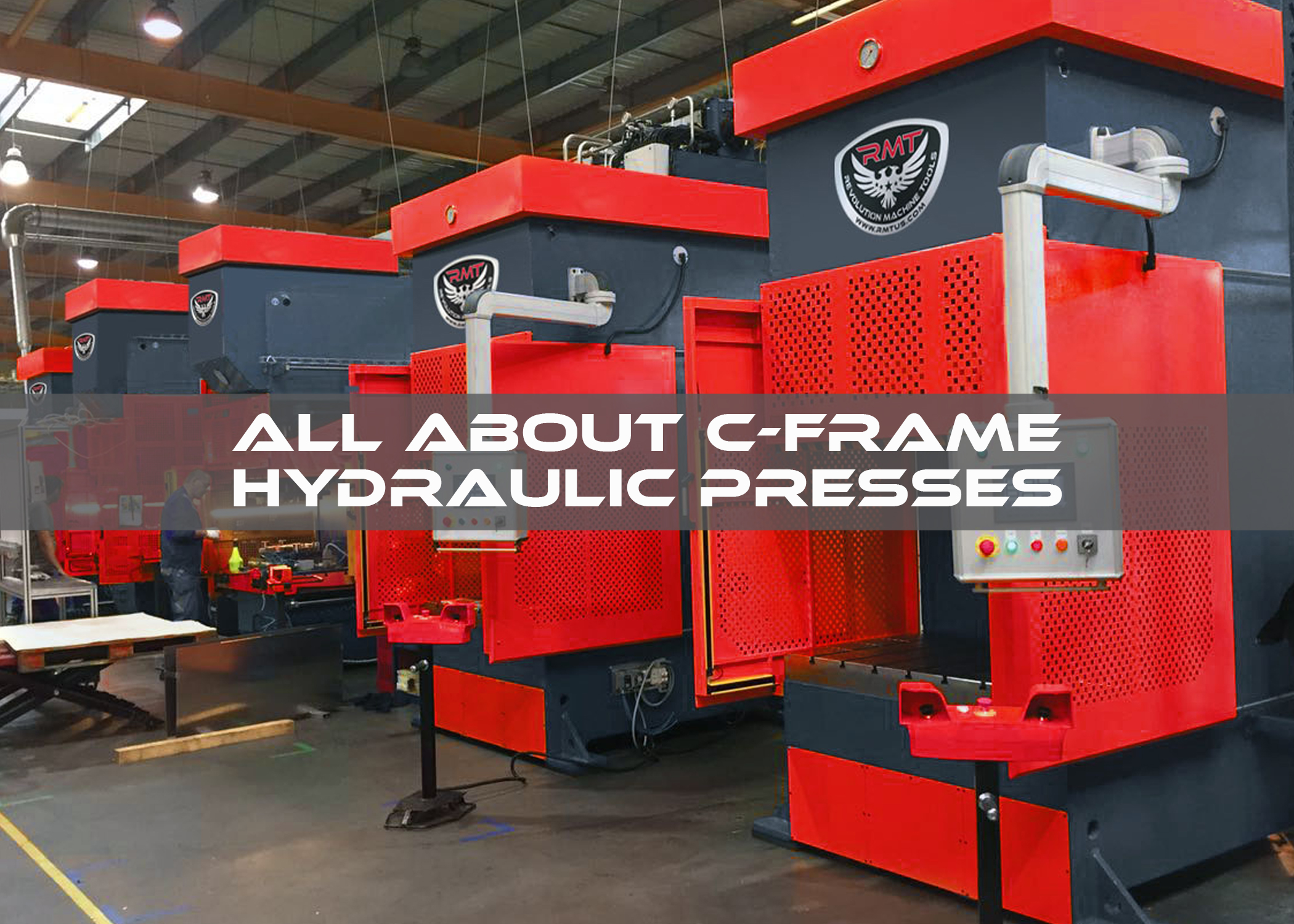

Hydraulic presses have become an essential piece of equipment in various manufacturing and industrial processes, with the C-frame hydraulic press being one of the most widely used types.

What is a C-Frame Hydraulic Press?

A C-frame hydraulic press is a machine that uses hydraulic force to apply pressure to a workpiece. It is named for its “C” shaped frame, which allows for a clear open space on three sides of the work area, making it easier to load and unload materials. The press works by utilizing hydraulic cylinders, which are powered by high-pressure fluid, to exert force on the material. This enables the machine to perform tasks such as stamping, forming, punching, bending, and even assembling parts.

The C-frame structure, unlike other press types such as H-frame presses, offers a greater degree of accessibility and flexibility, making it ideal for tasks that require precise handling of smaller parts or frequent adjustments.

A Brief History of Hydraulic Presses

Hydraulic presses, in general, have a long and storied history that dates to the 18th century. The first true hydraulic press was developed in 1795 by the French engineer Joseph Bramah. His creation, known as the “Bramah press,” used hydraulic pressure to exert enormous force on materials, and it marked the beginning of a new era in industrial manufacturing.

However, it wasn’t until the early 20th century that hydraulic presses became more common in industrial settings. The development of more efficient hydraulic systems, along with advancements in materials and manufacturing processes, made hydraulic presses more accessible and practical for mass production.

The C-frame hydraulic press, specifically, emerged in the mid-20th century as a more versatile and accessible alternative to other press designs. Its open-frame structure provided greater flexibility and allowed manufacturers to adapt the press for a wide range of applications, from automotive part stamping to metal forming.

Uses of C-Frame Hydraulic Presses

C-frame hydraulic presses are incredibly versatile machines that can be used across various industries. Some of the most common applications include:

- Metalworking and Stamping. One of the primary uses of C-frame hydraulic presses is in metalworking, where they are used for stamping, punching, and forming metal parts. These presses can shape and cut metal sheets into complex forms with precision and accuracy. The hydraulic pressure can be finely controlled, allowing manufacturers to produce parts with tight tolerances.

- Automotive Manufacturing. In the automotive industry, C-frame hydraulic presses are used to manufacture components such as body panels, chassis parts, and brackets. These presses are ideal for the high-volume production required in automotive manufacturing, providing the necessary force and accuracy to create consistently high-quality parts.

- Plastic and Rubber Forming. C-frame hydraulic presses are also widely used for plastic and rubber forming, where heat and pressure are applied to mold materials into specific shapes. The presses can handle both thermoplastic and thermoset materials, making them ideal for producing components like gaskets, seals, and automotive interior parts.

- Assembly and Joining. C-frame hydraulic presses are commonly used for assembly and joining applications, such as rivet insertion, spot welding, and part assembly. The controlled pressure exerted by the press helps ensure that components are joined with the right amount of force, without damaging delicate parts.

- Laboratory and Research Applications. In research and development settings, C-frame hydraulic presses are often used for testing the mechanical properties of materials. The precise control of pressure and force allows engineers and other scientists to perform a variety of tests, such as compression, bending, and tension tests, on small samples.

- Forging. C-frame hydraulic presses can also be employed in forging applications, where metal is heated and then shaped under pressure. This is particularly useful for producing high-strength components, such as gears, shafts, and tools, that require exceptional durability and toughness.

Advantages of C-Frame Hydraulic Presses

C-frame hydraulic presses offer a variety of advantages over other types of presses, particularly the H-frame presses and mechanical presses. Some of the key benefits of C-frame hydraulic presses include:

- Enhanced Accessibility. The C-frame structure provides clear access to the work area from three sides, allowing operators to easily load and unload materials. This open design also makes it simpler to install fixtures, tools, or special components for specific tasks.

- Precise Control. Hydraulic systems offer excellent control over the amount of pressure and force applied to a workpiece. This is a significant advantage when producing parts with tight tolerances or when performing delicate operations. The operator can fine-tune the hydraulic pressure to achieve the desired result, which is difficult to replicate with mechanical presses.

- Flexibility. C-frame hydraulic presses can handle a wide range of materials and operations. The versatility of these presses allows them to be used in multiple industries for different applications, from metalworking to plastic forming. This flexibility is one of the primary reasons they remain a popular choice for manufacturers.

- Compact Design. The compact nature of the C-frame press makes it ideal for operations where space is limited. Its smaller footprint, compared to other press types, allows it to fit into more confined areas of a production floor or lab, making it easier to integrate into existing production lines.

- Quiet Operation. Hydraulic presses, in general, tend to operate more quietly than mechanical presses, which can produce a significant amount of noise due to their moving parts and mechanical components. This makes C-frame hydraulic presses a more pleasant and safer choice in work environments where noise levels need to be minimized.

- Durability and Reliability. Hydraulic presses are known for their robustness and longevity. Proper maintenance can allow these machines to function for many years without significant performance degradation. The simplicity of hydraulic systems also makes them less prone to breakdowns, which is important in high-volume manufacturing.

- Energy Efficiency. Hydraulic presses are often more energy-efficient than their mechanical counterparts, especially when they are used for tasks that require variable pressure or force. The ability to adjust pressure according to the needs of the operation reduces energy consumption and can lead to significant cost savings.

Finding a Good Brand of C-Frame Presses

C-frame hydraulic presses are produced by various manufacturers and sold through many different dealers. Locating the right brand of hydraulic C-frame press or any piece of fabrication equipment can become critical to your fabrication business’s success. Some suggestions for finding the perfect press for your production include:

- See if the manufacturer offers a wide range of presses and other metalworking products. They are more likely to be a reliable brand if they offer multiple models in different capacities and with different optional accessories, such as a choice of controls.

- See if they offer a robust warranty.

- See if they (or their dealer) offer onsite repairs and remote troubleshooting.

- See if they offer readily obtainable replacement parts. Also check to see if you need to order proprietary parts through them or if electrical and hydraulic parts can be purchased off-the-shelf from a local supply house.

- See if they have videos available (training, operational, promotional, or otherwise) that you can watch to see their machines in action.

- Look online for reviews and ask the manufacturer or dealer if they have sold any similar presses into your area that you would be able to see in operation and ask the customer(s) about their experiences with the company.

A good hydraulic C-frame press can solve many problems for a shop or manufacturer. Learn as much as you can about them before you make your purchase, and be sure to ask your sales consultant for help in matching a press to your current and future projects.