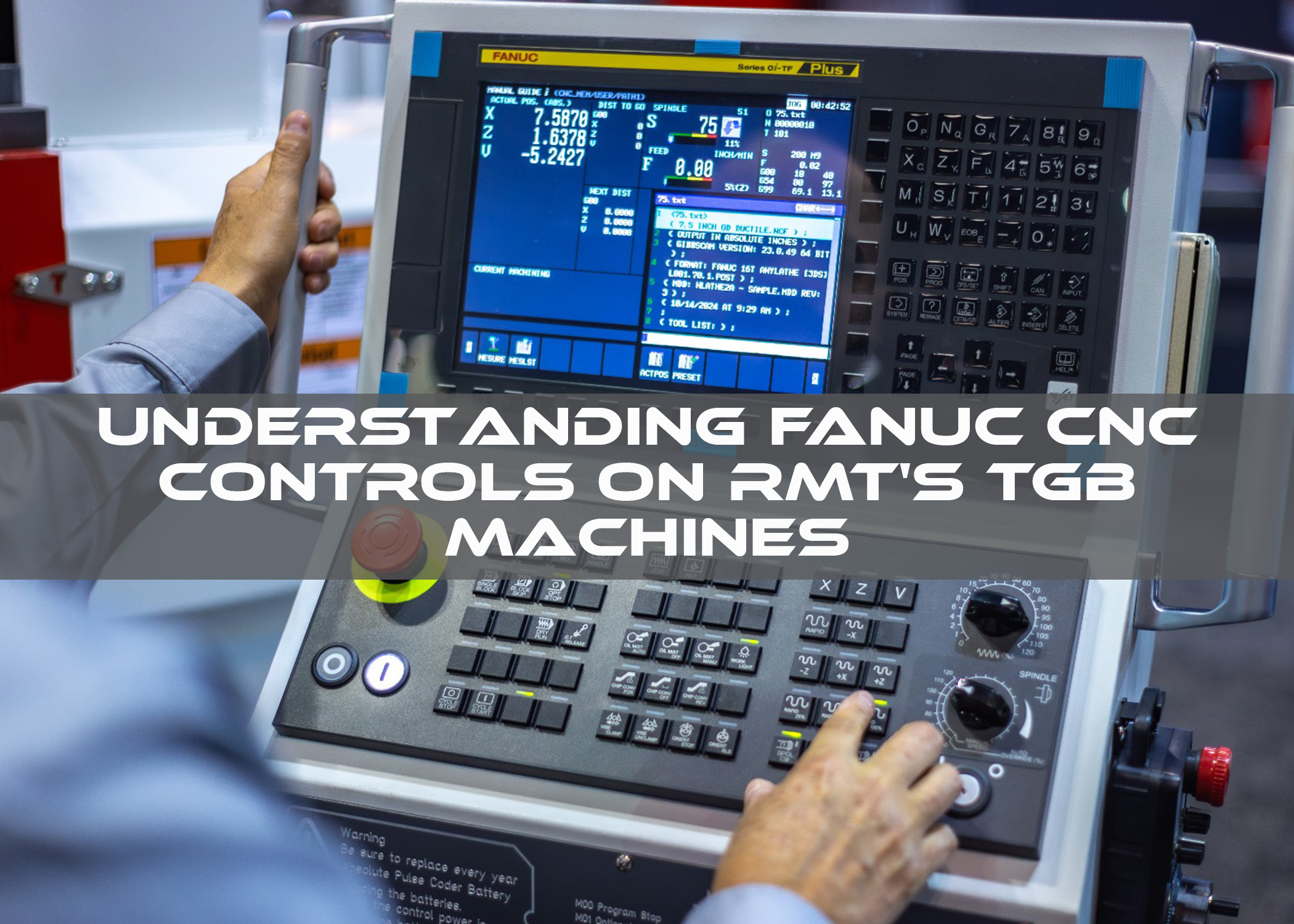

Understanding FANUC CNC Controls on RMT’s TGB Machines

Revolution Machine Tools carries a line of Pipe Spool Master™ machines capable of facing and beveling pipe and doing so while the pipe remains stationary. From the manual machines with those essential functions, other machines are equipped with (or can be upgraded to include) a basic CNC that will allow threading. Some have options for more advanced CNCs to be added, while the best models sport deluxe FANUC Series 0i-TF CNC units right out of the factory, including the popular, high-end TGB (Threading, Beveling, Grooving) machines.

Pipe Spool Systems

Pipe spool systems are a cornerstone of modern industrial piping, facilitating efficient construction, maintenance, and operation of pipelines across various industries. These systems comprise prefabricated sections of piping—commonly referred to as “spools”—that are manufactured off-site in a controlled environment and transported to the project site for final assembly. This approach streamlines construction processes, enhances quality control, and reduces on-site labor requirements.

Pipe Spool Master™ Series from RMT

Power plants, fuel refineries, chemical processing, and other industries that transport fluid and gas require robust piping systems. Fabricating the pipes onsite can lengthen construction time and risk quality, so most facilities will choose to have segments of pipe, known as pipe spools, fabricated and processed offsite in a more controlled environment.