A Pipe Spool WHAT?

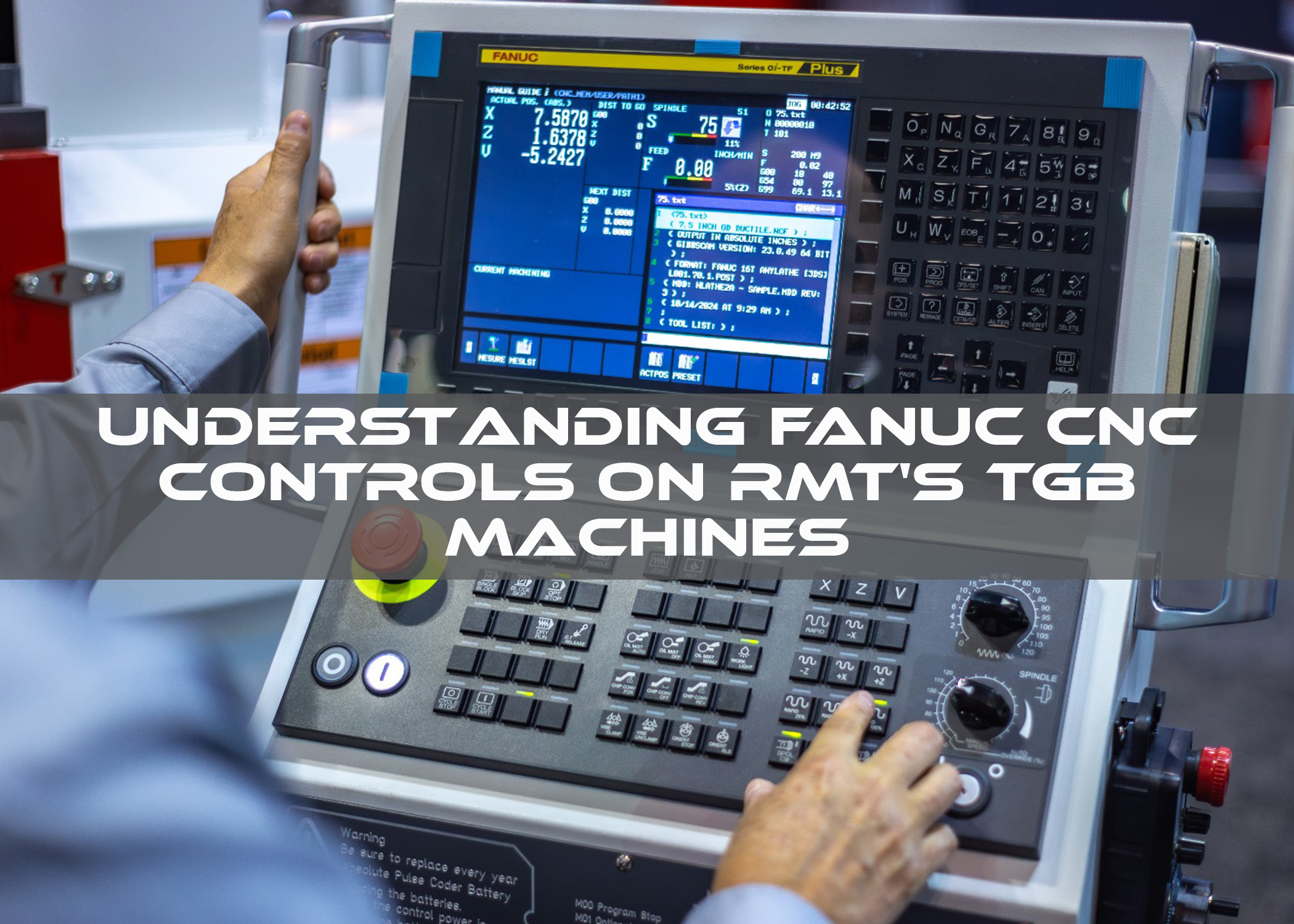

Revolution Machine Tools carries a line of Pipe Spool Master™ machines capable of facing and beveling pipe and doing so while the pipe remains stationary. From the manual machines with those essential functions, other machines are equipped with (or can be upgraded to include) a basic CNC that will allow threading. Some have options for more advanced CNCs to be added, while the best models sport deluxe FANUC Series 0i-TF CNC units right out of the factory, including the popular, high-end TGB (Threading, Beveling, Grooving) machines.

The Pipe Spool Master™ TGB 14 CNC and TGB 24 CNC machines offer a full range of threading, groove cutting, facing, boring, and more, thanks to their FANUC CNC Series 0i-TF controls. Ideal for precision CNC turning, the unit can control such diverse functions as turning, rounding, tapering, texturing, centering, milling, drilling, and tapping. If a user needs to bevel a pipe, the 0i-TF CNC from FANUC will allow the TGB machine to create a single bevel, a double bevel, a single V, a double V, a single J, a double J, a single U, a double U, compound J-prep, J-prep with back bevel, and compound J-prep with back bevel.

The FANUC Series 0i-TF CNC system is a high-performance, versatile, and user-friendly controller that serves as the backbone for many turning centers and CNC lathes throughout the industry. Renowned for its reliability, precision, and advanced functionality, the 0i-TF series is engineered to optimize machining processes while ensuring ease of use and maximum productivity.

Overview of FANUC Series 0i-TF

The FANUC Series 0i-TF is part of FANUC’s robust lineup of CNC controllers, specifically designed for turning applications. It supports multi-path control, enabling simultaneous execution of multiple machining operations. This capability significantly enhances throughput and reduces cycle times, making it a preferred choice for manufacturers seeking efficiency and high-quality production.

Equipped with a powerful processor and advanced motion control technology, the 0i-TF guarantees smooth and precise tool movement. Its open architecture allows for seamless integration with automation systems, robotics, and third-party software, contributing to smart factory implementations and Industry 4.0 readiness.

Some key features include:

- High-Speed Machining. The 0i-TF controller is engineered for high-speed processing, with rapid response to changes in machining parameters. Its look-ahead function can predict tool paths and adjust speeds dynamically, ensuring smooth transitions and reducing processing time. This feature is particularly valuable for complex part geometries and high-precision applications.

- Multi-Path Control. One of the standout capabilities of the 0i-TF is its multi-path control feature. This allows independent programming and operation of multiple tool paths simultaneously, optimizing workflow and reducing cycle times. This feature is especially beneficial for multi-spindle and multi-turret turning centers, enhancing productivity and machining flexibility.

- Intuitive User Interface. FANUC has equipped the 0i-TF with an intuitive, easy-to-navigate interface. Its color LCD screen displays real-time information on tool paths, machine status, and diagnostics. Operators can easily program and adjust settings using the conversational programming option, which reduces the need for extensive G-code knowledge.

- Advanced Diagnostics and Maintenance Tools. The 0i-TF comes with comprehensive diagnostic tools that monitor the machine’s health and performance. Predictive maintenance alerts operators to potential issues before they result in machine downtime, enhancing overall equipment effectiveness (OEE). The controller also supports remote monitoring, allowing technicians to perform diagnostics and updates off-site.

- Integration and Connectivity. Built with Industry 4.0 in mind, the 0i-TF supports Ethernet, MTConnect, and FANUC’s proprietary FOCAS communication protocol. These features enable seamless data exchange with factory networks, production monitoring systems, and cloud-based analytics platforms.

- Safety and Compliance. Safety is a top priority for FANUC, and the 0i-TF is designed with multiple safety features, including real-time monitoring of tool positions and collision detection. Compliance with international safety standards, such as ISO and CE, ensures that the controller meets stringent safety requirements for global manufacturing environments.

Operation of FANUC Series 0i-TF

Operating the 0i-TF is straightforward, with its user-friendly interface guiding operators through setup and execution. The system supports:

- Conversational Programming, which simplifies the process of creating machining programs with step-by-step prompts.

- Manual Guide i, a graphical programming interface that allows for easier part programming and simulation.

- Macro Programming, which enhances automation by enabling the creation of custom cycles and operations.

Additionally, the controller features Manual Data Input (MDI) for quick, on-the-fly changes and Jog Mode for precise manual control during setup and inspection.

A Perfect Control for a Perfect Pipe Machine

The FANUC Series 0i-TF is a versatile, high-performance CNC controller built for modern manufacturing demands. With its multi-path control, high-speed processing, intuitive interface, and robust connectivity options, it sets the standard for efficiency and reliability in CNC turning operations. Whether integrated into a small shop or a large production facility, the 0i-TF provides the precision, control, and versatility required to meet today’s machining challenges, especially on an RMT Pipe Spool Master™ TGB CNC machine.

Costing a fraction of the price of an equivalent through-spindle lathe, RMT’s TGB CNC machines process pipe more efficiently, while having much smaller footprints than lathes of the same capacity (since they only need to support one end of the pipe, with stands or a crane being used as required for the other end).

Call Revolution Machine Tools today for a competitive quote on your next Pipe Spool Master™ TGB CNC machine featuring a FANUC Series 0i-TF CNC control, and spin profit out of your pipes.