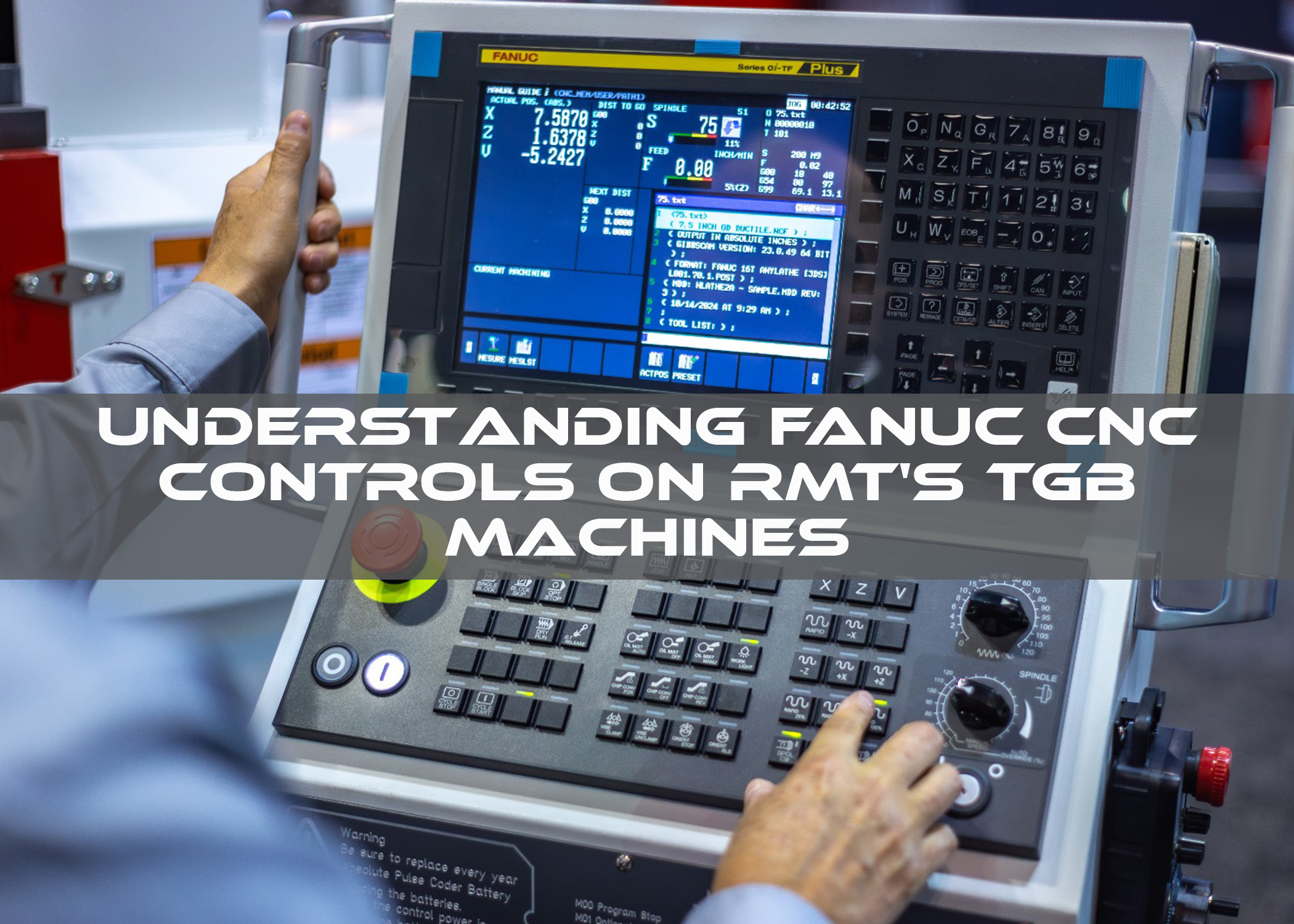

Understanding FANUC CNC Controls on RMT’s TGB Machines

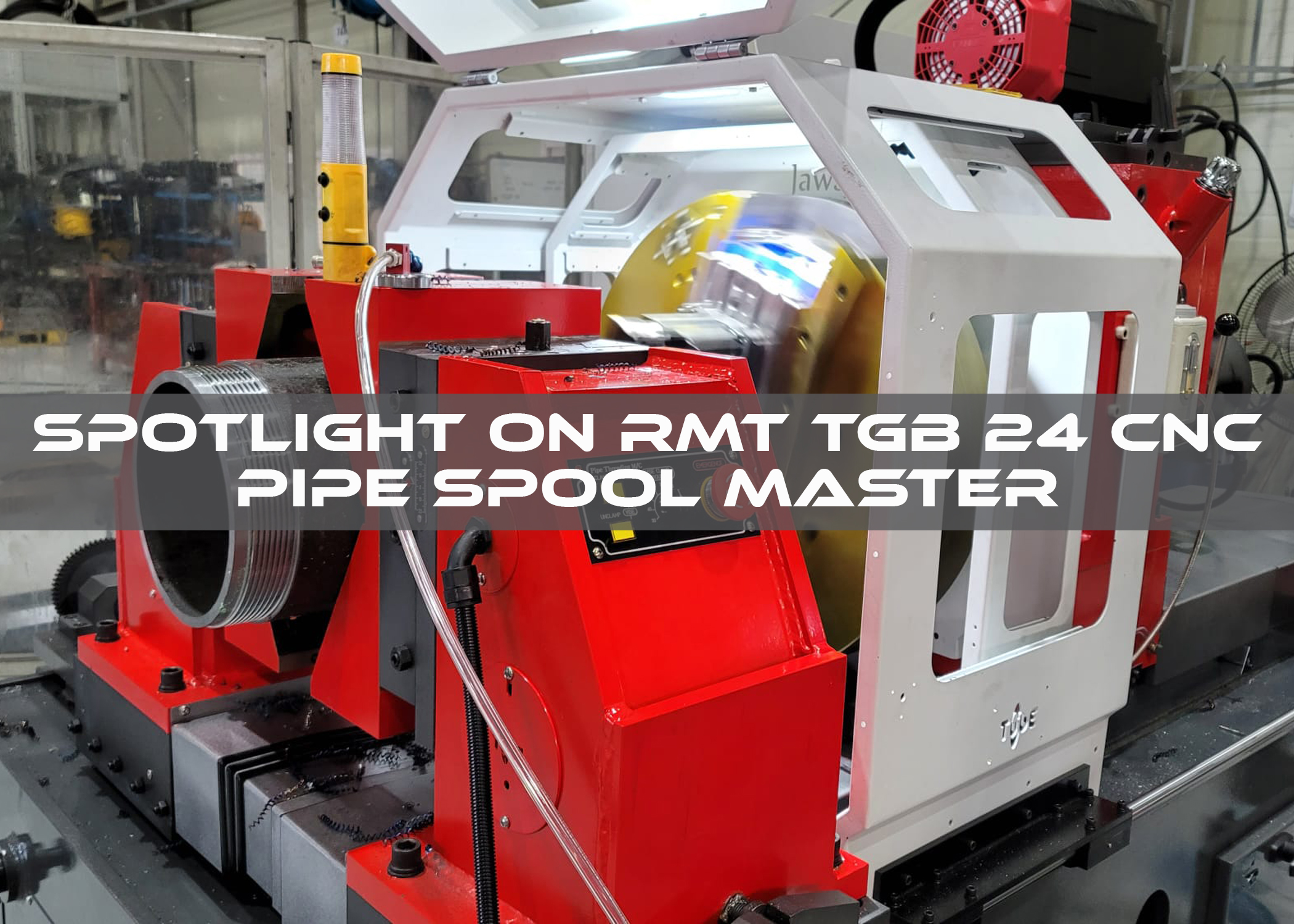

Revolution Machine Tools carries a line of Pipe Spool Master™ machines capable of facing and beveling pipe and doing so while the pipe remains stationary. From the manual machines with those essential functions, other machines are equipped with (or can be upgraded to include) a basic CNC that will allow threading. Some have options for more advanced CNCs to be added, while the best models sport deluxe FANUC Series 0i-TF CNC units right out of the factory, including the popular, high-end TGB (Threading, Beveling, Grooving) machines.

Pipe Spool Master™ Series from RMT

Power plants, fuel refineries, chemical processing, and other industries that transport fluid and gas require robust piping systems. Fabricating the pipes onsite can lengthen construction time and risk quality, so most facilities will choose to have segments of pipe, known as pipe spools, fabricated and processed offsite in a more controlled environment.

Spotlight on RMT TGB 24 Pipe Spool Master

A pipe spool is a prefabricated section of a piping system used in various industries, such as oil and gas, chemical processing, and power generation. Pipe spools are essentially segments of piping that are assembled in a controlled environment, such as a metal fabrication shop, before being transported to the installation site.