Plate Rolling Basics

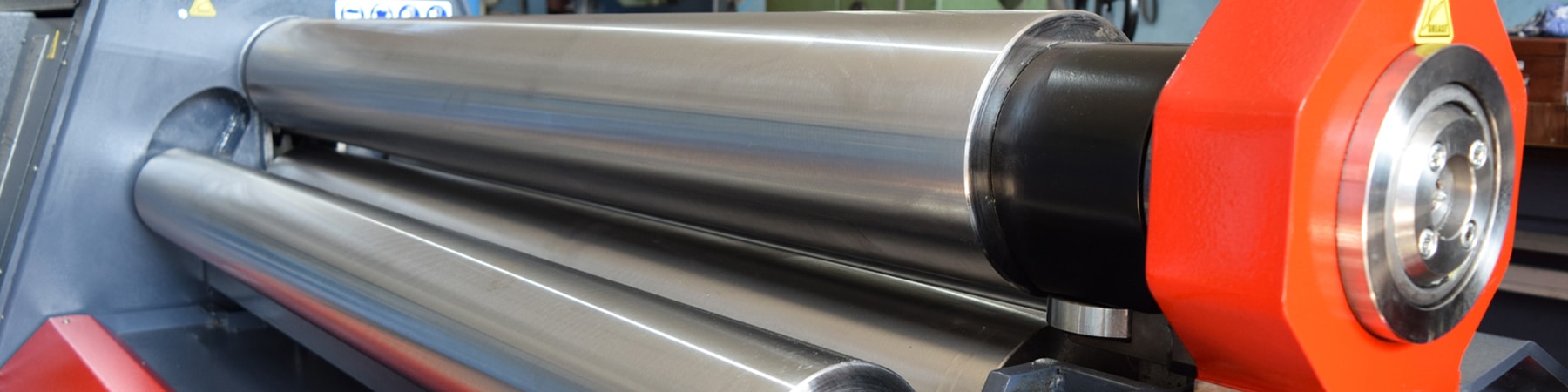

Those who begin a career in any aspect of metalworking quickly discover that shaping and forming metal sheets is one of the most important skills in the trade. Among the tools used to accomplish this, plate rolls play a vital role.

How to Buy a Used Plate Roll

A plate roll is an essential piece of equipment in many fabrication shops, enabling the bending and forming of metal plates into curved shapes and cylinders. Investing in a used plate roll can provide significant cost savings over purchasing a new machine, but it also presents some risks if proper precautions aren’t taken. By following a systematic approach, buyers can ensure they acquire a reliable, efficient, and suitable machine for their needs.

Plate Roll Options from RMT

The R&D Department at Revolution Machine Tools strives for excellence in the design of every plate roll and other metal fabrication machine that is produced and sold. RMT offers a fleet of hydraulic plate rolling machines with capacities to satisfy the exacting needs of any fabricator, each containing state-of-the art technology and enough standard features and available options to more than match the requirements of the job at hand.