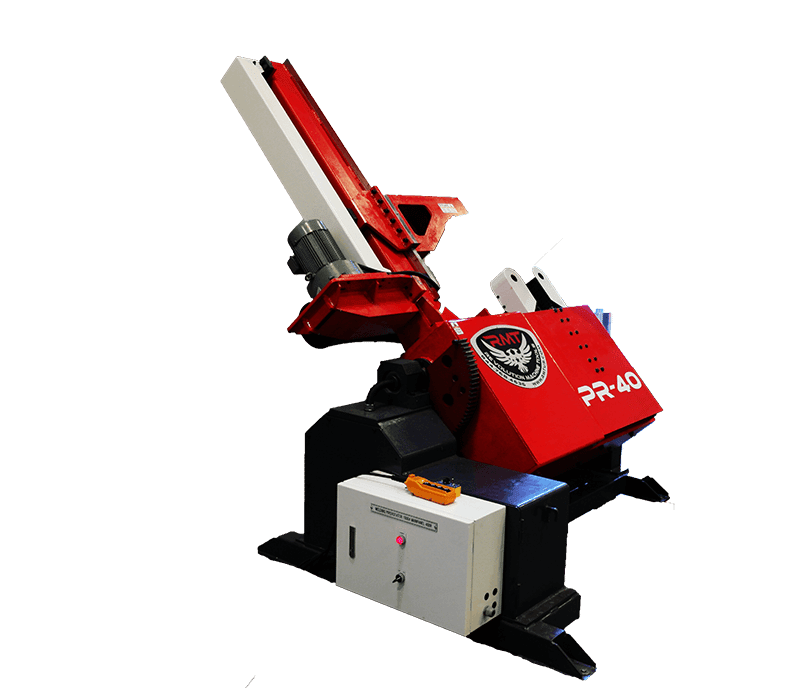

Description

PIPE ROTATOR FEATURES

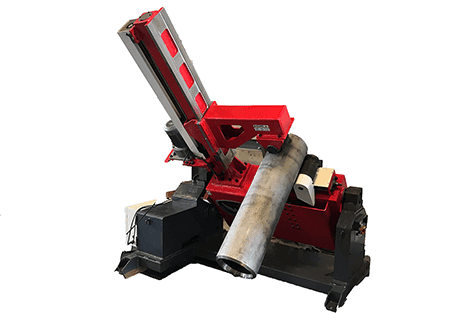

- Large Capacity Range For One Machine

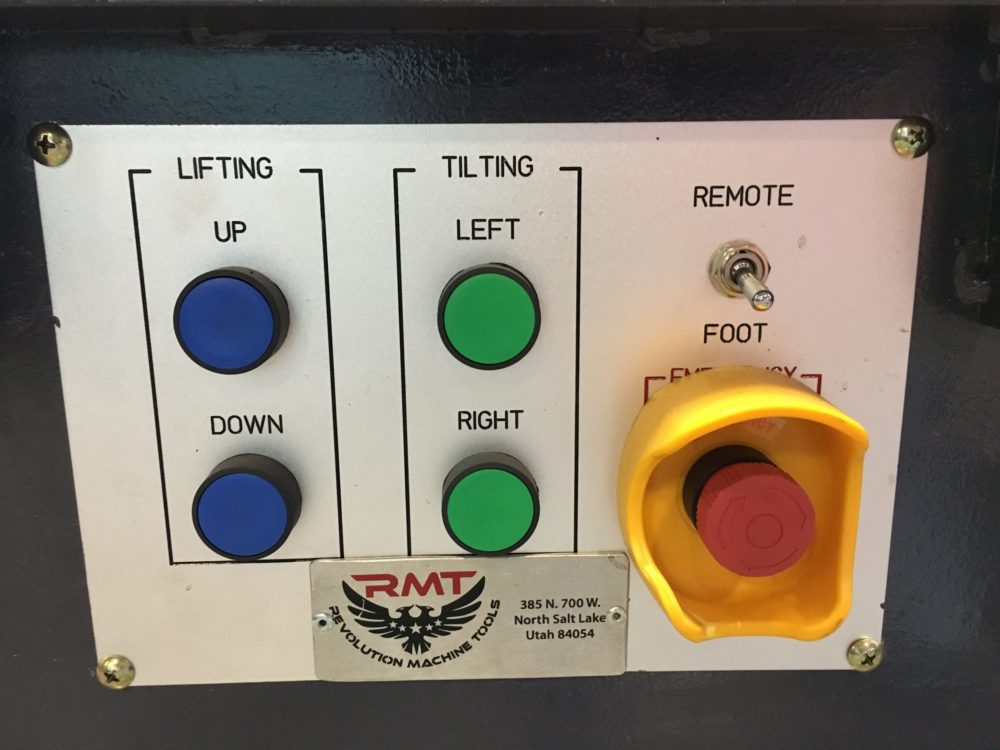

- Common Pass Line height (Ability to rotate various heights of pipe without interference)

- Wireless Foot Switch System (Optional)

- Tiltable (Achieve the perfect welding positions)

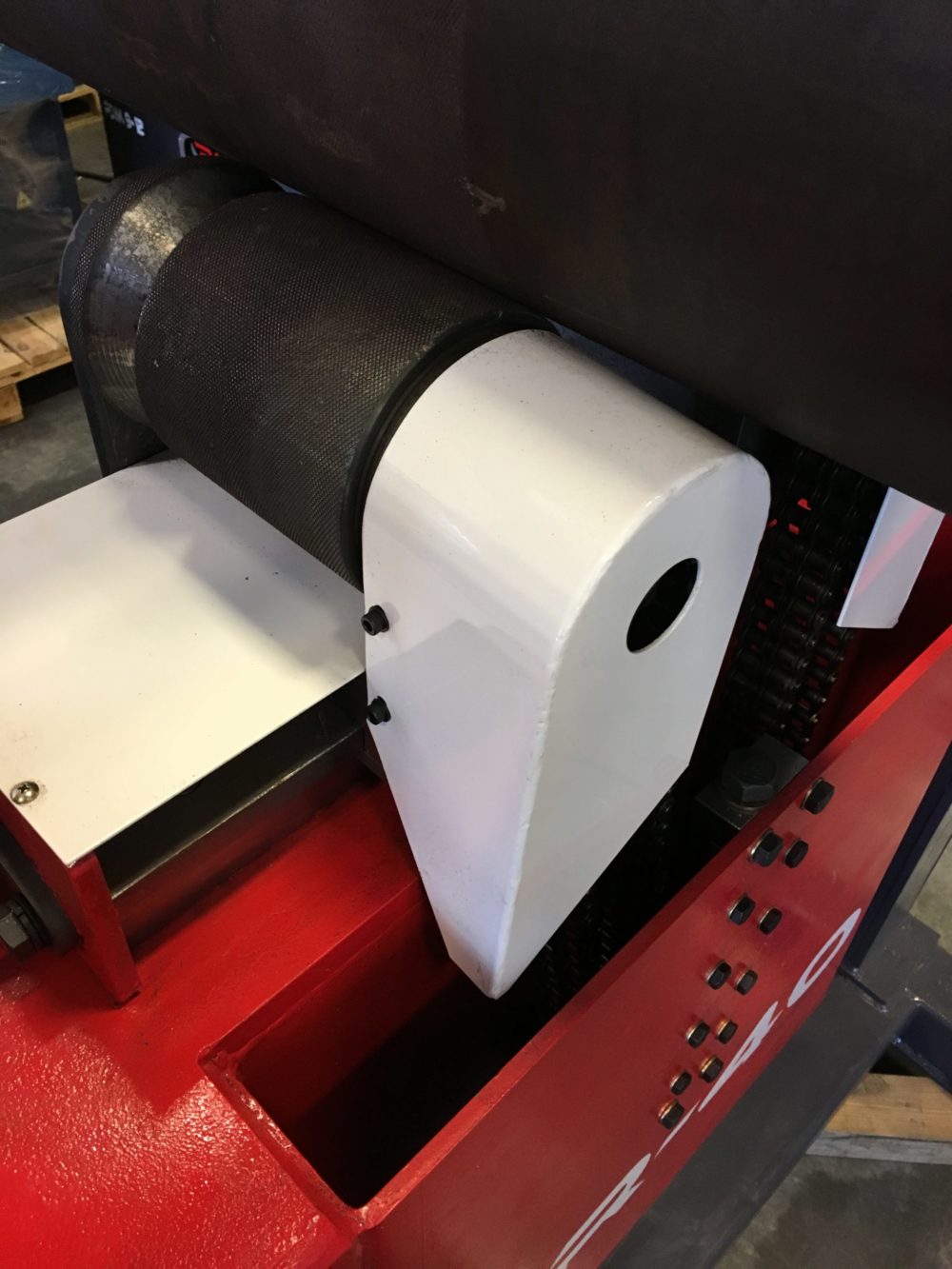

- Exchangeable Drive Rolls – For Various Material Types (Optional)

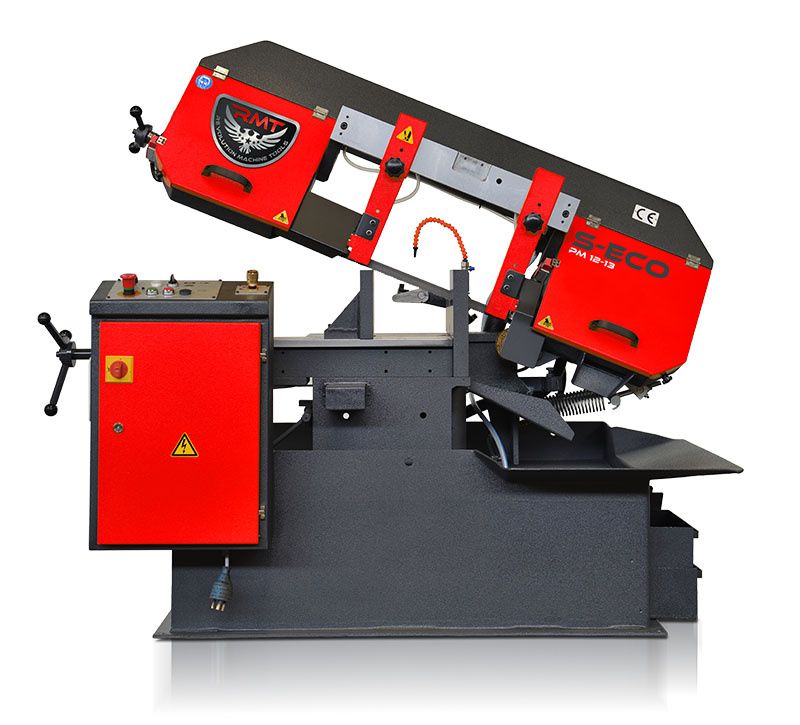

BUILT TO LAST

The foundation of all RMT™ Pipe Rotators is a solid, mono-block frame made from mill-certified, high-yield steel. As a result, RMT™ Pipe Rotators perform reliably year after year. We’re so confident in our frames that we offer a 10-year warranty with our standard machines.

The powerful hydraulics provide smooth motion resulting in precise movement positions to accuracies of .001”

ROTATE EFFICIENTLY

RMT™ Pipe Rotators can easily accommodate applications with large lengthy pipe with deep bends and those that require short pipe handling. Because of our different options for size and usage. Another thing special to RMT Rotators is the option for a wireless foot pedal. Without cords you’ll gain mobility and flexibility allowing your welders to move freely without trip hazards. Also equipped on the weld positioners is a variable speed remote that allows for precision rotational speed.

SMOOTH OPERATION

RMT™ machines are designed with state-of-the-art technologies that provide unparalleled accuracy and precision. This is the result of our world-class Research and Development departments that have been constantly perfecting our machines for decades, allowing us to consistently outperform competitor machines year after year.

ROTATE SAFELY

RMT™ Pipe manipulators were designed to maximize your safety with various features such as the optional wireless foot pedal. Resulting in fewer injuries from trips and falls. The main frame was purposely designed to allow for safe movement and employee safety surrounding the machine. Coupled with variable speed adjustment you can be sure that everybody in your shop will be safe from harm.

WHY CHOOSE RMT PIPE MANIPULATORS?

ACCURACY

RMT™ machines are designed with state-of-the-art technologies that provide unparalleled and precision. This is the result of our world-class Research and Development department that has been constantly perfecting our machines for decades, allowing us to consistently outperform competitor machines year after year.

ADAPTABLE

Our RMT™ machines are designed from the ground up by our expert engineers with only one goal: to build the best machines imaginable. By combining our unique machine designs with the highest quality materials available, we realized our goal and invented some of the most reliable and durable machines in the world!

EFFICIENCY

We understand the importance of a disruption-free production to your success, and have done everything in our power to maximize the efficiency of our RMT™ machines. We have meticulously identified and removed every hindrance to efficiency in our machines, providing you with the most seamless manufacturing experience imaginable.

SAFETY

Safe operation of heavy machinery for the operator and any bystanders is paramount to any successful enterprise, which is why RMT machines have a multitude of safety features in place, often times exceeding industry standards. We have even implemented our own innovative safety features when existing ones were inadequate or non existent.

FLEXIBILITY

RMT is committed to the universalization of machinery and machine tools, because it not only prevents our customers from having to reinvest in new tooling and accessories, but allows for remarkable flexibility. The enhanced flexibility and longevity of our machines provides for a significantly broader range of applications, maximizing value.

CUSTOMIZABILITY

The high customizability of RMT machines allows them to be individually configured for a plethora of projects, significantly reducing the quantity of machines you will need. We also specialize in custom engineered machines for those projects that simply cannot come to fruition without one. Regardless of the project, RMT can help you realize it!