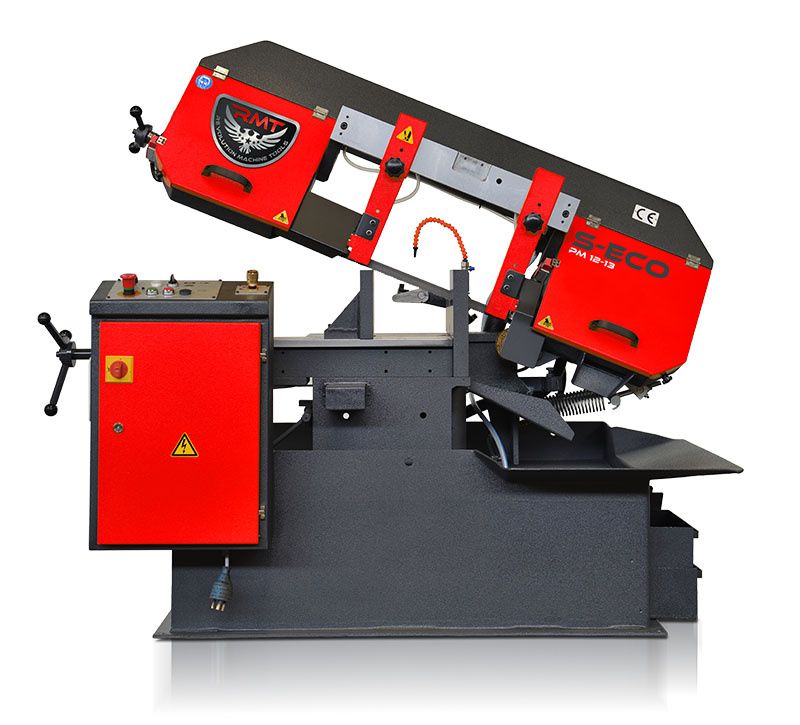

Description

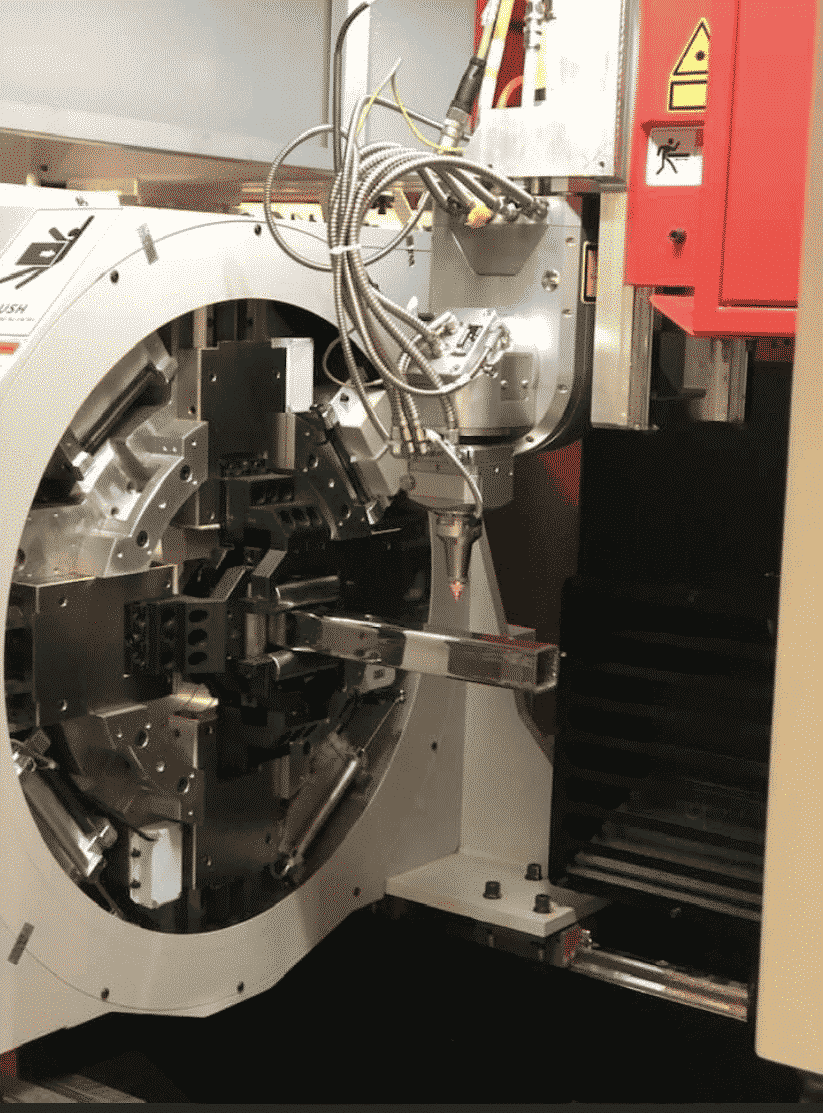

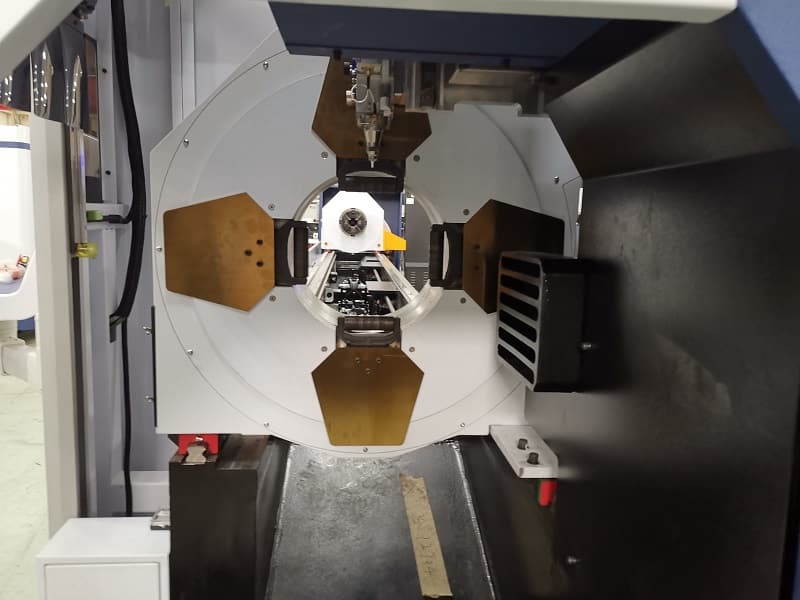

KYSON™ T5X – 1021 / 22 Tube Cutting Fiber Laser Features:

- 5-Axis

- System self-control, fully automatic loading and unloading system

- Tube groove cutting maximum angle is up to 45 degrees

- Tube cutter which is very ideal for cutting various standard tube materials, with tube diameter up to 10″

- Cuts round tube (outside diameter 0.5″ – 10″), square tube (0.5″ x 0.5″ – 7.875″ x 7.875″/edge length), rectangular tube, elliptical tube and flat elliptical tube special forms (similar to elliptical tube (0.78″ x 1.5″ – 4.72″ x 2.75″)

- This tube cutter is especially suitable for cutting normal type tubes rather than special tube types and open type tubes or frequently tube types.