Can You Leave A Bandsaw Unattended?

April 22, 2024

A Lively Debate The simple question was posed by a member of the Metal Fabrication Tips social media group: “Horizontal...

Read MoreRevolution Machine Tools™ (RMT™), founded by longtime industry leader Kyle Jorgenson, is a metal fabrication machine tools company. RMT™’s design team has created the most precise tools in the North American market today. We have partnered with leading manufacturers to build our designs to our stringent specifications in state-of-the-art manufacturing facilities. Kyle Jorgenson started in the Machine Tool industry working with his father, Roger Jorgenson, who founded Jorgenson Machine Tools in 1974. Roger taught Kyle how important relationships and customer service are and Kyle has built his reputation on those principles. RMT™ is supported by an ever-expanding team of industry professionals, which include design, marketing, service, and support, who have these same values and respect Kyle’s vision. Together, they are creating a Revolution in the Machine Tool industry.

LEARN MORE

At Revolution Machine Tools™, it is our passion to help others succeed. We believe that manufacturing is the backbone of our economy and that by providing the best solutions to make our customers successful is how we measure our own success.

In the words of the late (and fictional) Big Tom Callahan, "A Guarantee is only as good as the man who backs it up." We stand behind our machines and our customers are like partners. We work with you to make sure your machines run efficiently.

Our R&D team has designed some of the most innovative, strong, and precise machines on the market. Only quality materials are used to build our machines, and when you use the best materials and combine that with the best technology, you get the best machines.

April 22, 2024

A Lively Debate The simple question was posed by a member of the Metal Fabrication Tips social media group: “Horizontal...

Read More

April 15, 2024

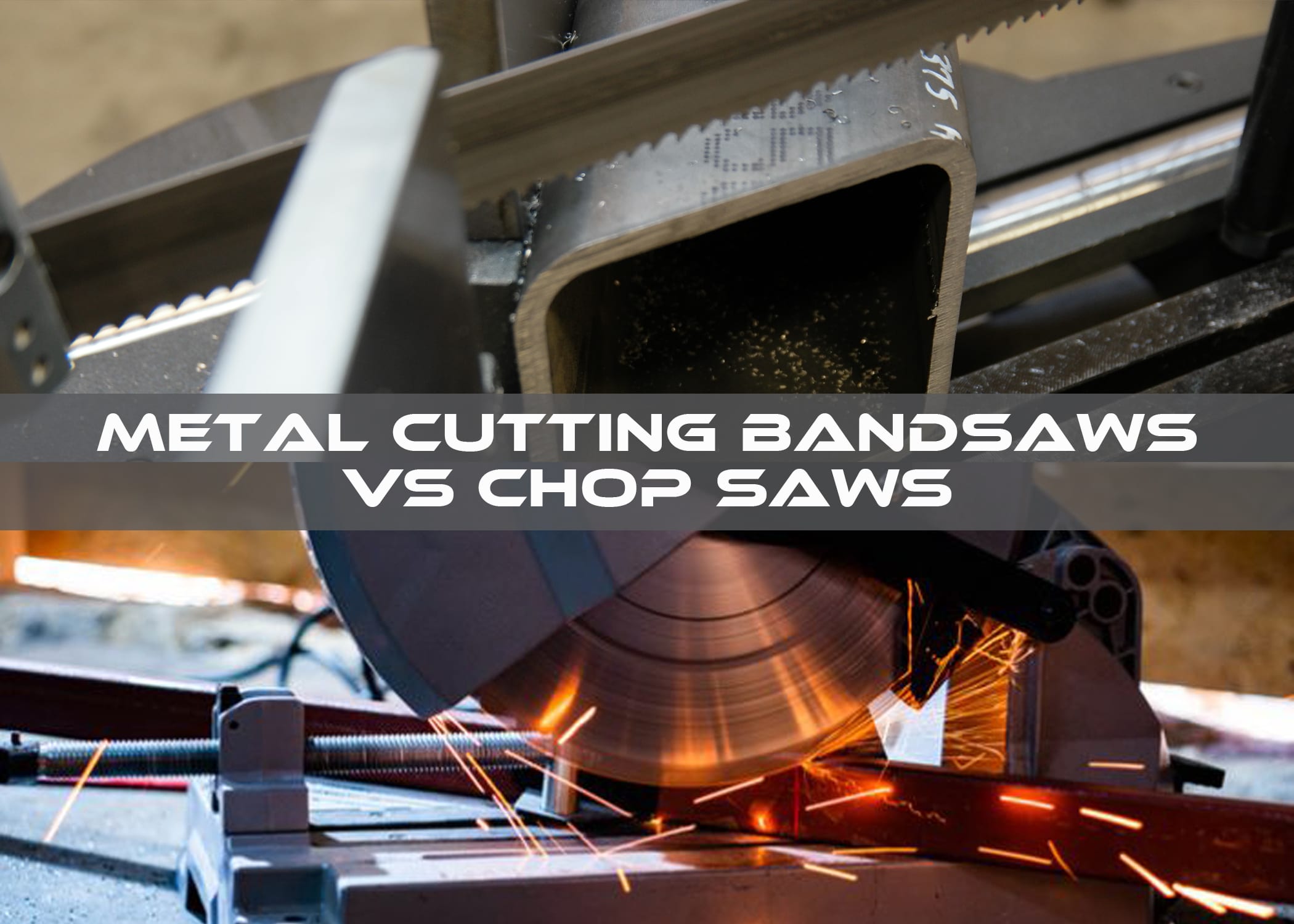

Surveying the Group A member of the Metal Fabrication Tips social media group posted this simple question: “Horizontal bandsaw vs....

Read More

April 8, 2024

Transforming Metal with Heat Almost as long as there has been metalworking, artisans have used heat to assist in their...

Read More