Surveying the Group

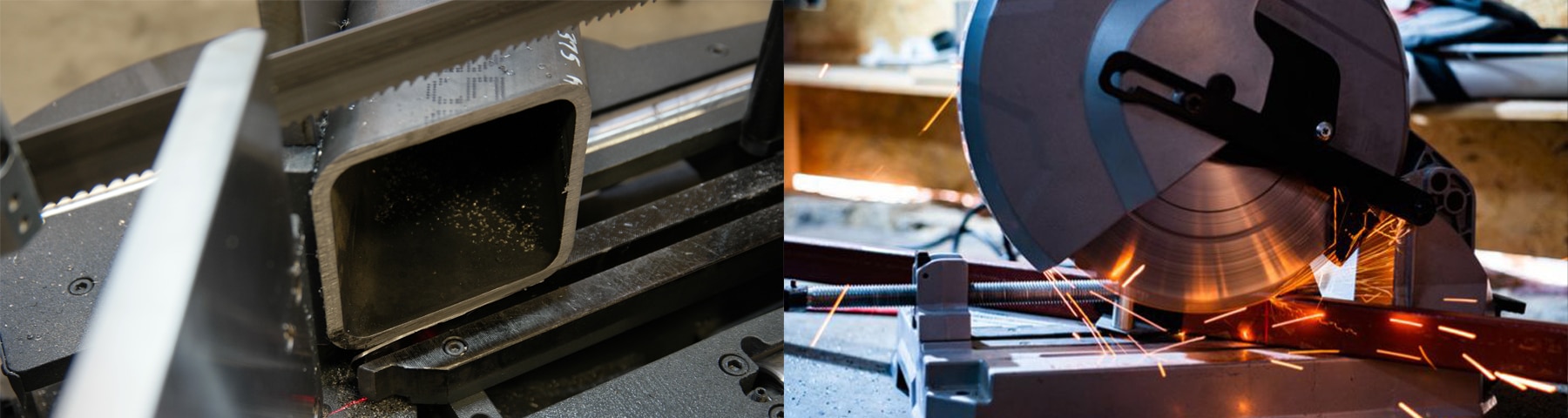

A member of the Metal Fabrication Tips social media group posted this simple question: “Horizontal bandsaw vs. chop saw?”

His fellow group members were quick to reply with their opinions:

- “Both have their places.”

- “Space was a big factor for me, so [name brand] saw was my choice, however a bandsaw is a lot better solution.”

- “One goes on your truck the other stays in shop, LOL, so both.”

- “Depends on the material of course.”

- “Bandsaw. Chop saw is loud as ****.”

- “Both.”

- “[Name brand] metal saw is better than either.”

- “Cold saw.”

- “Chop saw with super thin blade is efficient. Band saw is a bit slower, but no dust and clean cut.”

- “My cold saw cuts perfectly square every time. A big time-saver. I gave away my [name brand] vertical/horizontal band saw after 12 years of not using it, since I got the cold saw.”

- “My preference is horizontal/vertical bandsaw. It cuts great and blades are cheap. And I love the versatility of cutting smaller and detailed parts on a table in the vertical mode. I modified the table so it’s easy on and off. I don’t miss a chop saw all, but if I get another one, it’ll be a [name brand].”

- “I started out using cheap chop saws like the ones with giant grinder wheels but they’re extremely loud and the cuts are very dirty, and the material is hot when you’re done. I then upgraded to the [name brand]-type saws. That gave us a cleaner cut with less heat, but still loud and the teeth on the saw like to take small pieces of drop and fling them hard enough to implant them into a wall. We finally upgraded to a horizontal band saw with a coolant pump and reservoir. The result is very clean cuts, very quiet, cold to the touch, and no pieces of drop flinging across the shop. The only drawback is that it is a little bit slower than the chop saws, but it makes up for it by the fact that we can put multiple pieces in the band saw, push the button, and walk away to do other things while it cuts.” [That last line started a lengthy sub-thread about whether one should walk away from a running bandsaw.]

A Choppy Saw Distinction

It should be noted that several of the respondents who said “chop saw” were clearly talking about cold saws or other metal-bladed saws. Others understood the usually accepted difference—that chop saws refer to machines that use abrasive discs instead of metal blades—such as the person who chimed in with “_____ metal saw is better than either.” Conflating cold saws and other metal-bladed saws with chop saws is a remarkably common occurrence, as any casual search across the Internet will show. Even some manufacturers of metal cutting saws that use circular metal blades will refer to their machines as chop saws.

Cold saws are so-called because they run cold, as contrasted with other saws—especially chop saws—that run hot. Cold saws run at a low RPM and use coolant to transfer the heat from the metal workpiece to the chips that are discarded. Chop saws run at an extremely high RPM and generate a lot of heat because they are basically grinding down the material with an abrasive wheel rather than cutting through it with a saw blade. Cold saws and their blades are more expensive than chop saws and their abrasive wheels.

Budget and Application

Whether one chooses to use a bandsaw or chop saw to cut their material basically depends on two things: budget and application. Each tool is useful for certain projects, and a well-equipped shop will likely own both.

Some pros and cons comparing them include:

- Chop saws are good for ‘quick and dirty’ jobs. Bandsaws are generally slower.

- Bandsaws are cleaner. Chop saws create a lot of mess with abrasive dust.

- Parts cut on a bandsaw require less finishing work. Grinding or sanding will usually be needed with chop saw cutting.

- Chop saws are portable and can easily be taken to a job site. Most bandsaws are made to sit in place on a shop floor (though some small portable bandsaws are available on the market).

- Bandsaws are more accurate. Chop saws can tend to wander a bit while cutting.

- Bandsaws run quieter. Chop saws are loud.

- Chop saws are usually much less expensive than quality horizontal bandsaws.

- Multiple pieces can be stacked and cut on a bandsaw. Chop saws can’t do that.

- You technically can walk away (not very far!) from a running bandsaw for a minute.

- Chop saw abrasive wheels are usually a little cheaper than bandsaw blades.

- Bandsaws seldom create sparks. Chop saws could double as sparklers on the 4th of July.

- Bandsaws don’t heat the metal workpiece much. Chop saws really heat up the part.

- Bandsaws can be extremely versatile. Chop saws, not so much.

If you can afford both, your application will determine which type of saw you will want to use. If you are on a limited budget, deciding between saving up for a good bandsaw, buying a cheap bandsaw, or buying a chop saw should also depend on what you need for your projects now versus what you see yourself doing down the road.

It’s always a good idea to talk to a trusted metalworking machinery dealer about your current and future applications and see how they can help you find (and finance) the right machine for your exact metal cutting needs.