Did You See What I Saw?

To the average Joe on the street, if you say you are going to buy a saw, he probably pictures just a single type in his mind. It could be a chain saw, a jig saw or perhaps even a giant lumbermill saw like he used to see in cartoons as a kid. Chances are, if he doesn’t work with metal or wood, there’s likely not much difference in his mind between one saw and another.

Metal fabricators, on the other hand, are familiar with many names, types and configurations of saws, including abrasive saws, bandsaws (both horizontal and vertical), chop saws, cold saws, cutoff saws and hack saws. Still, even though a fabricator might know the “what” when it comes to different kinds of saws, he may not be as familiar with the “why.”

Choosing the type of saw to use for your metalworking project has little to do with personal preference and quite a bit to do with factors such as the size and composition of material you are cutting and what type of finish you want on your completed part. What follows are some advantages of the two major metal cutting saws on the market, cold saws and bandsaws.

Advantages of Cold Saws

While more bandsaws can be found in shops than cold saws, the cold saw definitely offers some advantages:

- Accuracy. Cold saws are extremely accurate in their cutting quality and are the go-to machine when a cut with a tight tolerance is needed. They are ideal for cutting certain profiles where quality is critical, such as thin-walled tubing. While bandsaws are flexible in their application to different materials and sizes, their blades are also literally flexible and can “wander” a little in the cut, affecting accuracy, something that is not a problem with a rigid cold saw blade. Cutting accuracy with a cold saw is +/- .004″, a much tighter tolerance than with a bandsaw.

- Blade Costs. Bandsaw blades can’t be sharpened and often break, making them extremely disposable. Cold saw blades, while usually more expensive than bandsaw blades, are reusable and can be re-sharpened around 30 to 40 times when they become dull. In addition, the downtime for a cold saw blade replacement is much shorter than for a bandsaw blade, adding up to additional savings in production time. Blades are often interchangeable between cold saw brands, making replacing them easier than the very precise details that have to be matched for a bandsaw blade. These aspects of cold saw blades provide a user with a much greater return on their investment than they would get with a bandsaw, even though they likely paid more for their cold saw.

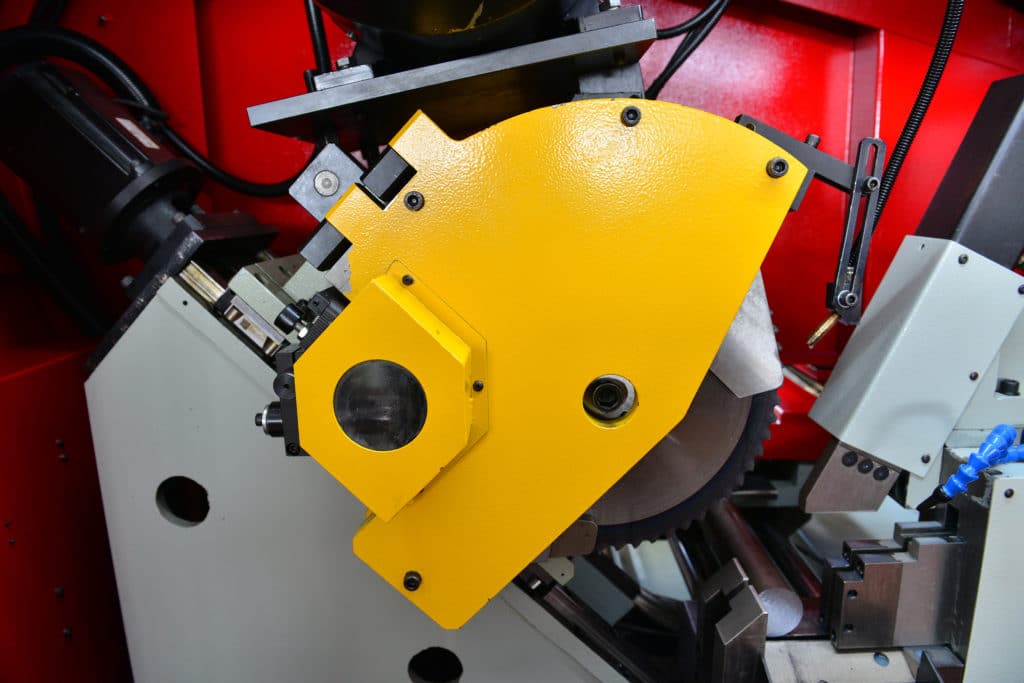

- Cooler Cutting. Cold saws get their name because they quickly enter and exit steel without creating excessive heat and their blade design—along with a good coolant system—transfers the heat that is generated into the chips removed from the material. This keeps both the blade and the material itself relatively cool. Cold saws are perfect for projects where the operator needs to avoid heating the material.

- Easy Setup. Cold saws are much easier to set up and run “right out of the box,” as it were, than bandsaws that need much more time for making sure everything is aligned correctly.

- Miter Cutting. Though many bandsaws are created with a mitering head or table to help them cut at an angle, circular saws like cold saws are extremely easy and efficient for miter cutting and are often preferred by fabricators.

- Overall Production Speed. While bandsaws generally cut faster, cold saws save time in the production of parts by making near-faultless cuts that don’t require any finishing. In addition, spending more for a high-speed carbide cutting saw can reduce cutting time quite a bit.

- Part Finish. Cold saws cut extremely clean, without leaving burrs on the part like a bandsaw does, so users get a near-perfect, “milled” finish on parts coming right from the saw. This not only eliminates the need for a secondary process like deburring or grinding, but also gives a perfectly square cut for tight joints.

If you need to produce cuts with clean finishes that don’t require deburring and you will only be cutting profiles that are less than five or six inches wide, a cold saw could be a good choice for your shop.

Advantages of Bandsaws

Bandsaws are more versatile than cold saws, hence their popularity in fabrication and machine shops. Advantages of bandsaws include the following:

- Ability to Shape. While most shops prefer the traditional horizontal bandsaw, vertical bandsaws are popular for those who need to cut curved or irregular shapes in smaller pieces, like a jigsaw would be able to do. They aren’t intended for large workpieces and extreme caution has to be used since operators have to keep their hands close to the moving blade.

- Better for Beginners. It doesn’t take a rocket scientist to run a horizontal bandsaw, so those learning basic fabrication functions can quickly master the basics of bandsaw cutting, especially with tasks that don’t need extreme accuracy.

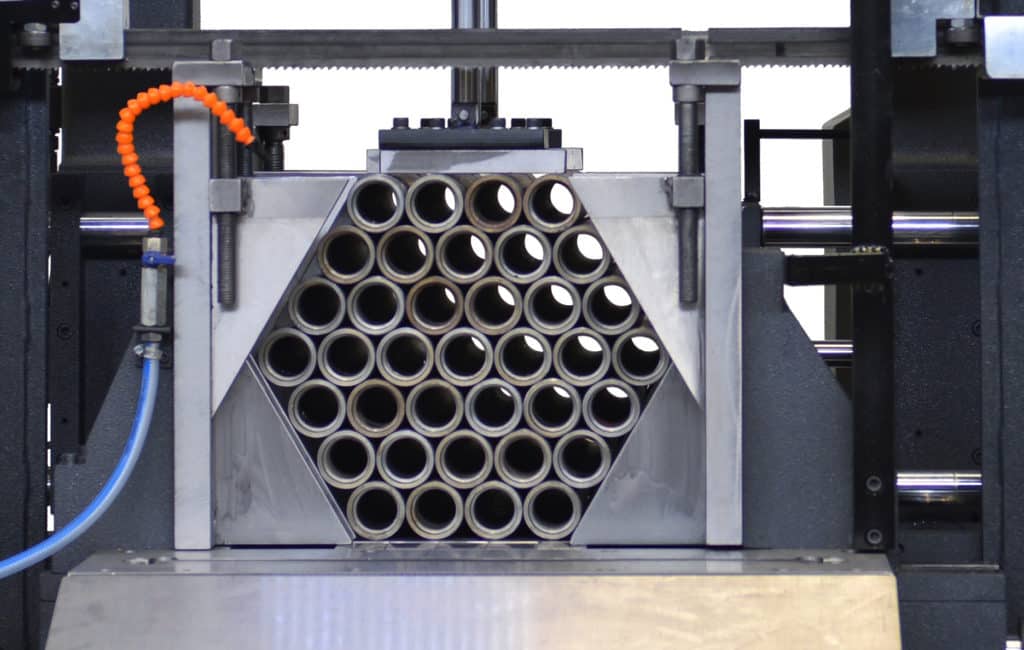

- Bundle Cutting. Cutting several identical profiles bundled together can only be done by the wider capacity bandsaws.

- Cost. Bandsaws are generally significantly less expensive than cold saws and allow a user to get the largest cutting capacity for their particular budget.

- Cut Size. Bandsaws offer larger cutting capacities than cold saws, both for width and for thickness of workpieces. A cold saw is attached at the center to the rest of the saw assembly so it can only cut very shallow pieces with the whole blade or very narrow pieces using only the side of the blade. In contrast, a bandsaw can use nearly the entire exposed section of the blade to cut a workpiece and do so all across the material at the same depth, something the curved cold saw blade can’t. In addition, bandsaws can be built much, much larger than standard cold saws.

- Cut Speed. The straight blade of a bandsaw makes contact with—and therefore cuts—more material than the curved blade of a cold saw. The evenly distributed tooth load allows for uniform and generally faster cutting.

- Kerf Size. The kerf—the width of material removed in a cut—is smaller with a bandsaw blade than a cold saw. While it may seem to be a minor thing, over the life of a saw it adds ups to a noticeable cost savings on material.

- Power Usage. Bandsaws will generally cut the same material as a cold saw using much lower horsepower.

- Repetitive Jobs. Many bandsaws have programmable workstations that allow them to perform repetitive tasks for a project, something less common with cold saws.

- Tough Materials. Bandsaws can cut a wide variety of materials, including harder workpieces than a cold saw can handle. Bandsaw blades are available in different configurations with a diverse range of hardness options for the teeth, so selecting the right blade for the job can do wonders.

Bandsaws are ideal when producing really clean-cut parts isn’t an issue, such as when cutting stock for other machining or fabrication processes. If pristine edges are required, then bandsaw users have to plan on grinding or deburring the workpiece following cutting.

Even though cold saws are normally more accurate than bandsaws, paying top dollar for a high-quality bandsaw can allow a user to come fairly close to the performance of a cold saw, thanks to today’s advances in technology.

If you need to cut a wide variety of material and sizes, and don’t need finished parts coming straight from the saw, a bandsaw could be a good choice for your shop.

Apples and Oranges

There is no “right answer” in the question of which is better, a cold saw or a bandsaw. There’s only the right answer for you, and what’s right for you today could be very different a year from now.

In order to purchase the correct saw for your needs, you need to look at not only what projects you are working on currently, but also predict what your future production requirements will be. What types of materials will you be cutting? What will be the largest workpiece diameters? Will you be doing angle cutting? How about cutting bundles? How accurate do you need your cutting tolerances to be? Will the saw only be used in short runs, or for long periods of time? Budgeting or borrowing to obtain the best saw for your long-term needs will save you money and headaches down the road.

In a nutshell, if you only buy one saw: for a smoother finish on smaller jobs, choose a cold saw; for larger and more diverse jobs, choose a bandsaw. Some shops, however, will decide to purchase both if and when they can afford to do so, and some will also have multiple bandsaws in different sizes and configurations as their budgets allow. (Even then, some materials may be too hard for regular saws, so an abrasive saw or other cutting machine might also have to be purchased to accommodate them.)

Regardless of the saw you select, make sure to keep the machine in good working order and follow manufacturer guidelines for its operation, such as using coolant during cutting. Both cold saws and bandsaws will work for many of the same projects, so find the machine that best fits your specific applications and budget and take good care of it so that it can serve your cutting needs for a long time to come.