What’s the Angle on Miter Bandsaws?

When William Newberry applied for a patent in England in 1808 for his concept of a bandsaw, he was trying to devise a way to make a straight cut through wood quickly and efficiently. He likely had no idea that his invention would later be adapted to cut metal, and to be able to do so not only straight, but at a 30°, 45°, or 60° angle as well.

Nowadays a mitering metal cutting bandsaw is a common tool in machine shops and metal fabrication facilities alike. As bandsaw technology has progressed, their operations have simplified, especially regarding angle cutting. In old style miter bandsaws, the vise would move, shifting the workpiece around. This required a larger footprint on the shop floor to run the machine. The newer models feature a swiveling head, often along with the table, leaving the material stationary, always oriented in the same direction. This makes the modern miter saw ideal for working with longer stock lengths and tighter workspaces.

Advantage of a Miter Bandsaw Over a Standard Bandsaw

While the need for a bandsaw in cutting stock down to size is essential for a metalworking shop, being able to cut at an angle through a profile like a square tube or angle iron is an important capability for the shop creating square bases or frames or doing decorative work.

Once angle cutting became an available feature in bandsaws, demand for the option increased to the point that most manufacturers today offer single or double miter cutting as a standard part of the package on a good number of their smaller and mid-sized machines. With the cost of adding a mitering aspect to a bandsaw has decreased, and the stability of quality-built machines has increased, there are few, if any, arguments for choosing to buy a straight-cut saw instead of a mitering one.

Even if a shop “never” does miter cutting, there will likely be a day where an exception to that rule is required, necessitating a time and money-consuming outsourcing of a project to a job shop that can facilitate the cut. Spending a little more for a miter feature when buying a bandsaw can easily pay for itself over the life of the device, while expanding the potential customer base for a shop in the meantime.

Advantage of a Single Miter Over a Double Miter Bandsaw

“Well,” one might reason, “if I’m buying a miter bandsaw, I may as well get one that miters both directions.” That’s not a bad idea, depending on two things: whether you miter that much and whether you can afford it.

While more and more bandsaws are equipped with a double miter feature these days, the simple fact is that they are generally more expensive than their single miter counterparts. While adding a miter option to a bandsaw gives a shop more flexibility, expanding to a double miter might not be as cost-effective for the facility that does very little in the way of angle cutting.

A single miter saw is the more affordable choice for the smaller fab shop, and when a second miter is needed in a piece—perhaps a length of square tubing that requires a point at the bottom to be driven into the ground as a post—the workpiece can be removed and inverted to make the second cut. Unless a shop does substantial miter work, a single miter bandsaw should fit the bill for them nicely.

Single Miter Bandsaws from RMT

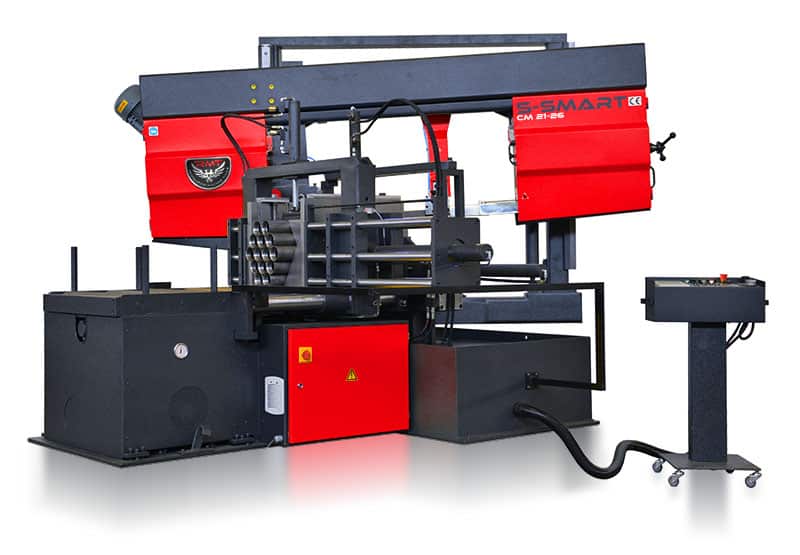

An argument that has been made against buying miter bandsaws is that many manufacturers are unable to provide some higher-end features like bundle cutting into their bandsaws that also miter cut. Here at Revolution Machine Tools, however, we know that fab shops need to be able to provide their clientele with as wide of a range of production metalworking services as possible. That’s why we offer saws like our S-SMART CM 21-26, which is a dual column single miter band saw that has an available option to add hydraulic top clamping for use in bundle cutting.

Whether you need a small, inexpensive single miter bandsaw, or a top-of-the-line NC controlled automatic angle cutting piece of bandsaw technology, RMT offers a variety of mitering saws to fit your specific circumstances. Check out our lineup:

- 12″ S-ECO PM 12-13 Manual Pivot Type Single Miter Bandsaw | Cutting capacity of 12.6″ round or square at 0°; 11.8″ round at 30° (9.8″ square); 10.2″ round at 45° (7.1″ square); 6.3″ round at 60° (5.9″ square)

- 12″ S-FAB PM 12-24 Semiautomatic Pivot Type Single Miter Bandsaw | Cutting capacity of 12.6″ round or square at 0°, 15° 30°, and 45°; 10.2″ round at 60° (8.9″ square)

- 12″ S-SMART PM 12-24 Automatic Pivot Type Single Miter Bandsaw with NC Control Panel | Cutting capacity of 12.6″ round or square at 0°, 15° 30°, and 45°; 10.2″ round at 60° (8.9″ square)

- 13″ S-SMART PM 13-15 Automatic Pivot Type Single Miter Bandsaw with NC Control Panel | Cutting capacity of 13″ round or square at 0° and 30°; 13″ round at 45° (11.4″ square)

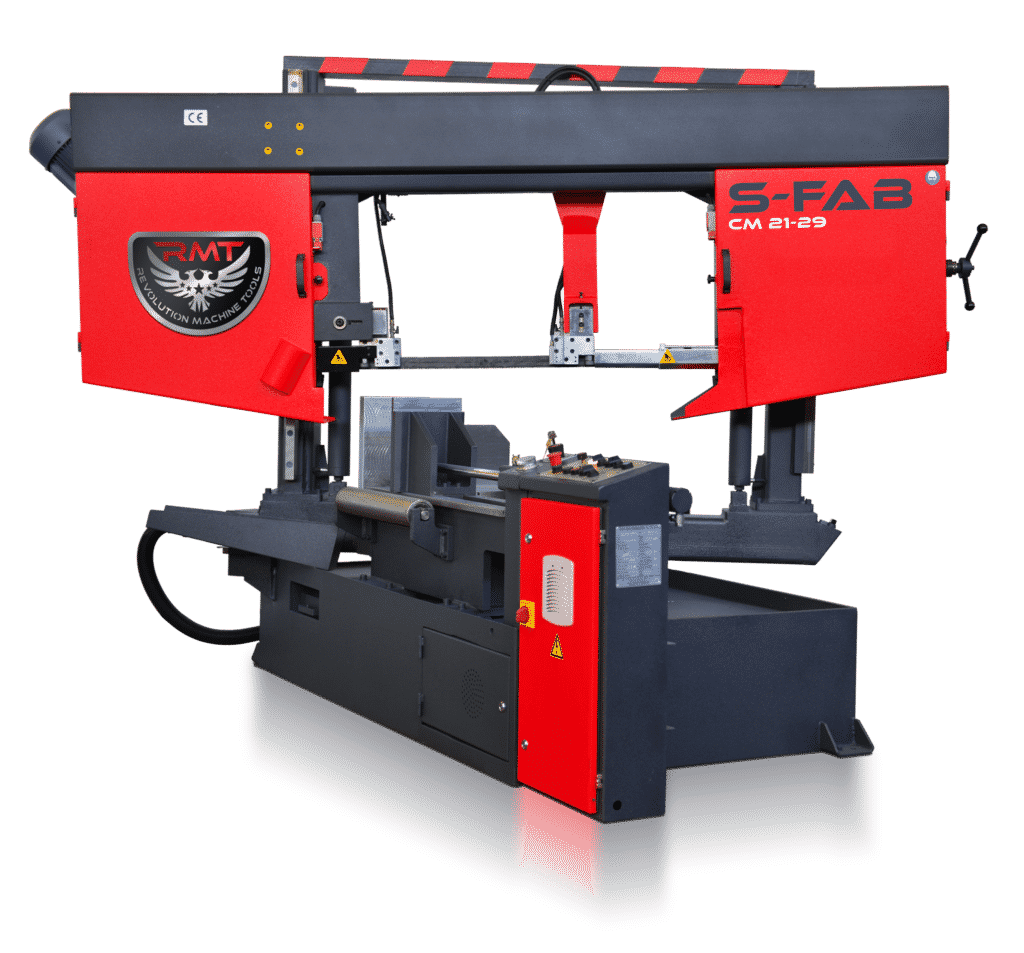

- 21″ S-FAB CM 21-29 Semiautomatic Column Type Single Miter Bandsaw | Cutting capacity of 21.3″ round or square at 0° and 30°; 20.1″ round at 45° (17.7″ square); 10.6″ round at 60° (9.8″ square)

- 21″ S-SMART CM 21-26 Automatic Column Type Single Miter Bandsaw with NC Control Panel | Cutting capacity of 21.3″ round or square at 0° and 30°; 20.1″ round at 45° (17.7″ square); 10.6″ round at 60° (9.8″ square)

- 30″ S-FAB CM 30-31 Semiautomatic Column Type Single Miter Band Saw | Cutting capacity of 31.9″ round and 30.3″ square at 0°; 27.6″ round and square at 30°; 21.9″ round and square at 45°; 12.6″ round at 60° (12.2″ square)

Angling in on the Best Miter Bandsaw Deal

When it is time to buy your next mitering bandsaw, be sure to consult a trusted machinery consultant, like the representatives at Revolution Machine Tools. A good salesperson will take the time to point out all the pros and cons of the different types of saws, as well as detailing all the optional equipment that can make your day-to-day work easier and more productive, such as a laser cutline indicator and misting equipment.

They will also make sure you comprehend any details that have to be understood when moving into a single miter bandsaw. For example, a good rep will make sure to point out that mitering reduces the cutting capacity of the bandsaw, depending on the chosen angle, as the working envelope becomes smaller when the head is turned away from a perpendicular cut on the material. A poor rep may try to strongarm a customer into buying an inadequate machine just to get rid of an old clunker on the sales floor.

Regardless of where you buy your next piece of metalworking equipment, please be sure to give Revolution Machine Tools a call for a very competitive quote. You will find a knowledgeable staff ready to assist you and ensure that you are well taken care of before, during, and long after the purchase has been made.