Multiple Methods of Metalworking

Metal fabricators and machinists are two vastly different creatures. Not to say they couldn’t go out for a friendly drink together, but they have very distinct ideas regarding how someone should properly go about shaping raw metal into a finished part. Perhaps the only thing they completely agree on is how most engineers seem to consistently design parts that can’t be realistically produced.

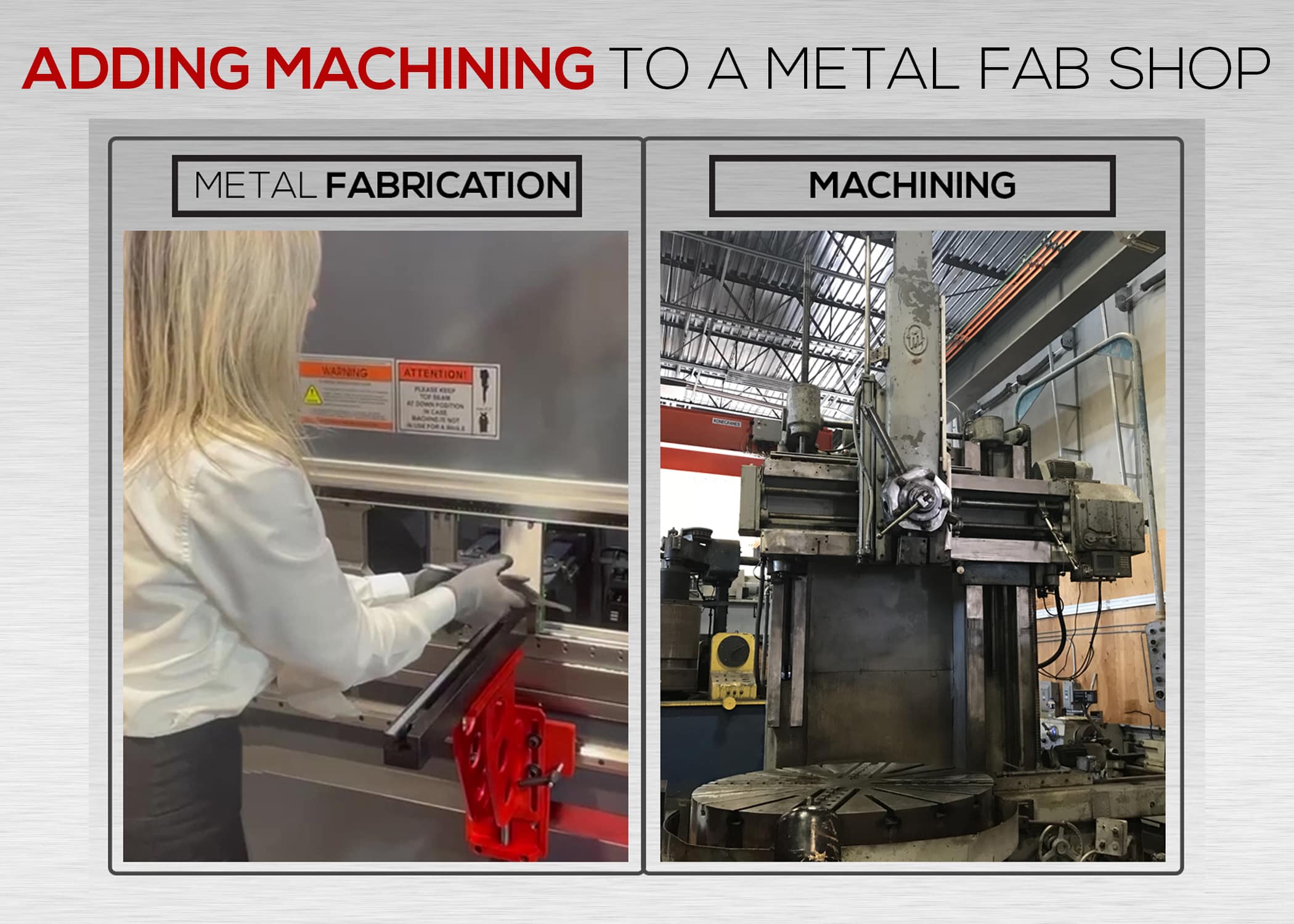

The fields of machining and fabrication are really two sides of the same coin, however, both being essential processes within the larger category of metal manufacturing. Although technically all metalworking activities can be said to “fabricate” a finished metal part, the term fabrication usually refers to the procedure of “forming,” wherein pressure is exerted to permanently change the shape of a piece of metal. Machining, on the other hand, removes material to whittle a workpiece down to its ultimate state.

Sculpting is a good metaphor to define what fabricators and machinists do, while distinguishing their methods at the same time. Both types of metalworkers are like sculptors, but where fabricators are akin to artists who mold their work from clay, machinists are better compared to those who chisel their work from a block of marble. One shapes by rearranging material, the other by removing it.

Rather than being competing professions, the work of machinists and fabricators complement each other, both adding to the diversity that is the business of metalworking. While there’s something to be said for a worker or an entire shop that specializes in a single discipline, the flexibility to branch out to other processes of metal manufacturing can offer some significant advantages in the marketplace.

Boosting the Bottom Line by Branching Out

Just as multiple welding shops have found it profitable to add fabrication work as a sideline, many modern fabrication businesses have likewise started to add internal machine shops to diversify the ways they can serve their clientele.

Some large machining jobs will likely still have to be farmed out to others, but three noteworthy benefits can be seen by fab shops that begin doing most of their “chip” work inhouse:

- Competitive Advantage. Unless a machinist buddy owes them a favor, profit is lost when a fabricator subcontracts out part of a job that can’t be performed onsite. Having the right equipment on the floor with qualified operators standing by will cut down on additional costs that have to be absorbed to keep bids low or passed on to the customer.

- Greater Productivity. Waiting for parts to come back from a third party can cause huge bottlenecks in the output of a business. By keeping everything internal, processes can be properly prioritized by shop management instead of being held hostage to outside situations. Workflow will be smoother while lead times improve.

- Better Quality. As the old saying goes, “If you want something done right, do it yourself.” Project managers can keep track of quality control at every stage of a job if all processes are performed under one roof, and on-staff employees are better able to understand and embrace company standards of excellence than outsiders could ever do.

While running an inhouse machine shop can be a great support for fabrication operations, the business that adds that capability may want to consider branding themselves as a one-stop metalworking facility, equally qualified in handling any type of machining or fab project that might come through the door. With economic upheavals always a possibility, being able to lean on one part of the business if work for the other department should ever get scarce could make the difference at some point about whether the lights stay on or not.

Managing a Migration to Machining

Adding machining to a metal fab shop requires more than just a decision to move ahead. A carefully planned out strategy is needed to ensure the company doesn’t make any serious missteps during the expansion.

The transition should be a slow and careful one, cautiously following sound principles of budgeting. Machines should be added as a shop is able, starting with smaller lathes and mills before expanding to things like CNC turning centers and vertical machining centers.

Some factors that should be considered along the way include:

- Making sure there is sufficient room in the shop to expand, keeping in mind an efficient workflow.

- Understanding the market and adapting where possible to market demands.

- Recognizing the different mindsets, cultures, and needs that exist between machinists and fabricators.

- Hiring or training operators prior to the arrival of each new machine.

- Setting up standards of quality and accountability from all shop workers, such as implementing ISO certification.

- Cross-training operators between machines and departments where appropriate.

- Programming CNC machines offline to not tie up operators.

- Appreciating the different safety concerns that come with chip-making machines.

- Maintaining relationships with other machine shops and identifying when it’s appropriate to job out projects to them.

- Keeping abreast of new metalworking technologies and implementing them when possible.

Opportunities for Other Operations

The supplemental capabilities that derive from an inhouse machine shop will add value to any fabrication business, potentially bringing in far more than enough profit to justify the initial investment in equipment and training.

The more proficiencies that a shop can offer, the more competitive it will be in the overall metalworking marketplace. Once machining has been firmly integrated, a fab shop may want to examine opportunities to expand into other metal manufacturing processes. Some that might be worth consideration include:

- Additive Manufacturing (3D metal printing)

- Joining (arc welding, spot welding, brazing, riveting, etc.)

- Molding (casting and/or powder metallurgy)

- Surface Working (through heat or coatings)

For the metal fabrication facility that wants to be able to address all their customers’ metal parts needs while streamlining operations and being able to have better control of the finished products will want to take a serious look at adding machining and other metalworking services to their repertoire.