The Age of the Fiber Laser

“Since the invention of the laser, we have entered into a new industrial revolution,” Professor William M. Steen wrote in Laser Material Processing (Springer-Verlag, London, 1991). The actual Industrial Revolution was launched during the 1700s, thanks to the development of the steam engine, which allowed humans to use powered machinery to perform far greater feats in manufacturing and processing materials than simple manual labor could previously accomplish. Likewise, the coming of the CO2 laser changed the face of metal cutting, etching, and marking in a way undreamed of by metalworkers of previous generations.

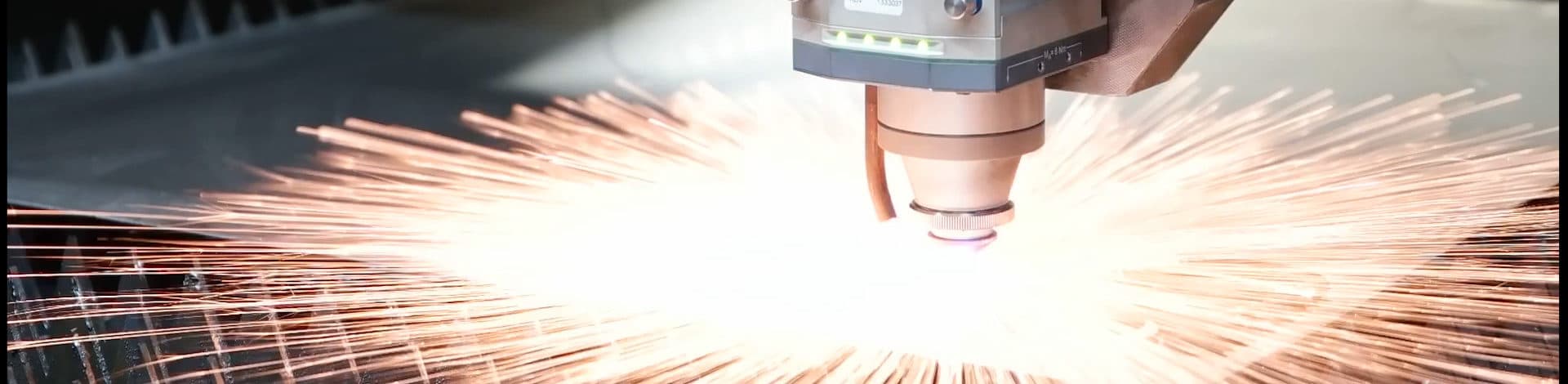

A significant leap forward came with the innovation of the fiber laser, with its simplicity and efficiency providing increased advantages for metal fabricators, not to mention expanded uses in everything from medical procedures and telecommunication to simple laser pointers. The age of the fiber laser has brought about advances even more revolutionary and mind-boggling than any before it.

What Is a Laser?

Originally coined as an acronym for Light Amplification by the Stimulated Emission of Radiation, the term “laser” soon entered everyday usage as a noun universally understood to mean a machine that could focus light into a narrow, straight beam. People came to talk about “laser beams” that could travel great distances and even burn through materials because of their concentrated energy, making them a recurring theme in science fiction.

Laser energy doesn’t occur in nature but is artificially created so that the emitted light is spatially coherent. This means that the photons stay in phase and travel together in a single direction, maintaining the same frequency and color along the beam. Instead of spreading out like the full range of light from a standard lightbulb, the light waves produced by a laser all have similar wavelengths and therefore can be focused as a straight line.

The laser light is created, as its acronym implies, by the stimulated emission of electromagnetic radiation that is optically amplified into a high-power beam. In a procedure called “pumping,” energy is supplied via light or electricity to a “gain medium,” which is a material such as a gas or a crystal containing specific ions. The gain or amplification of the energy comes about through the “stimulated emission” of photons from atoms in the gain medium. This happens as photons from the pump source interact with the electrons of these atoms, causing them to transition from a higher energy state to a lower one, releasing the new photons in the process. The new photons are of the same phase as the source ones, and they all travel together in the same direction, causing a chain reaction surge of coherent light.

Laser Development

Noted physicist Albert Einstein theorized the “stimulated emission of radiation” concept in a paper published in 1917, a year after he proposed his famous general theory of relativity. He postulated that 1) an isolated atom that is excited can emit photons to return to a lower state of energy; 2) light passing through a medium could stimulate the creation of more light; and 3) photons would tend to travel together in the same state. He put forth that if a photon of the right wavelength were to be fired near an excited atom, it would stimulate it to emit its photon in the same direction and at the same frequency, and together these photons would gather more photons to join them.

It took several decades for other scientists to put Einstein’s ideas to the test. In the 1950s, Charles Townes and Arthur Schawlow came up with the concept of placing facing mirrors on either side of a gain medium in a contained space. Photons could reflect and go back and forth, causing even more photons to be emitted of the same wavelength. Gordon Gould came up with the same notion of using mirrors and worked extensively in the new technique of optical pumping energy into the gain medium. Gould also thought up the phrase “light amplification by stimulated emission of radiation” and its acronym “LASER.” The first working laser was built by Theodore Maiman in 1960 at the Hughes Aircraft Company, using a pink synthetic ruby as the gain medium.

While the first optical fiber laser was invented the next year by Elias Snitzer, the early prototypes could only emit a few milliwatts, far short of what was needed for commercial applications. While waiting for the science to catch up with the concept, the invention of the CO2 laser in 1964 by Kumar Patel at Bell Labs in New Jersey took the world by storm. Both cheaper and more efficient than the ruby laser, CO2 lasers became the mainstay in metal laser cutting for the remainder of the century.

As high-powered models were able to be developed in the 1990s, fiber lasers began being used more in industry, but it would take until after the first decade of the 21st century had passed for them to start becoming a popular choice for fabricators.

Fiber Laser Basics

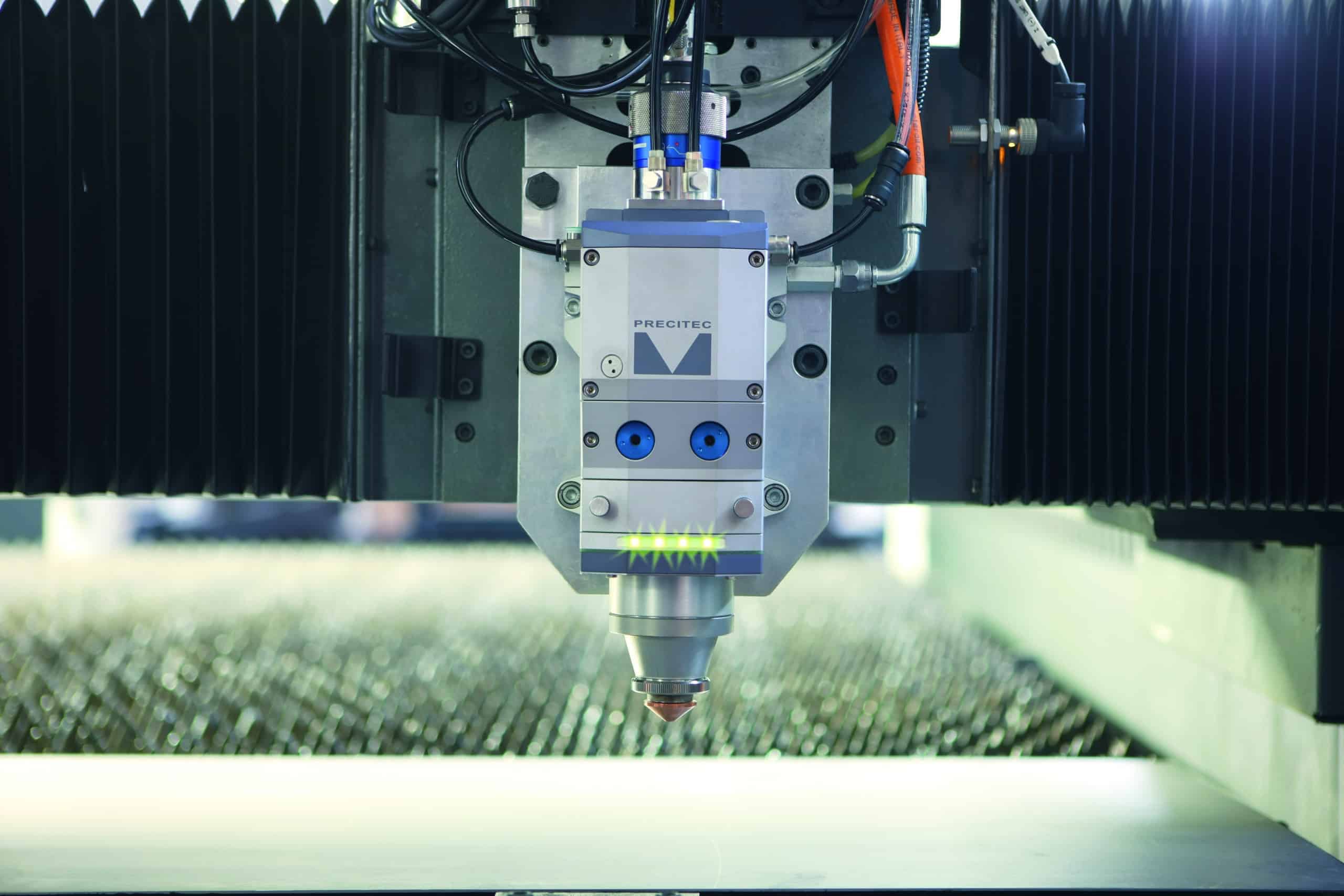

Unlike CO2 lasers that use an electrical discharge to excite gas molecules to create a beam, fiber lasers are solid-state machines that generate light with diodes serving as the pump. The light of several diodes will usually be combined before being introduced to the gain medium, which in this case is a spool of optical fiber which has been “doped,” or intentionally implanted with impurities such as ytterbium, erbium, or other rare earth elements. The doping elements help create and maintain a specific wavelength of laser light as they are “excited” by the energy from the diodes.

While fiber lasers don’t use mirrors, they do have a fiber Bragg grating at either end of the optical fiber medium. These are sections of glass containing stripes that change their refraction index, making them reflective and allowing them to amplify the light as it resonates between them. While the fiber Bragg grating at the pump end of the assembly has high reflectivity, the one near the output has low reflectivity to allow the light that has been created in the medium to exit. This amplified light is then collimated (made accurately parallel) and focused by a lens onto the material being cut.

Fiber lasers are becoming the most popular type of metal cutting laser due to the many advantages they offer over traditional lasers like CO2. Fiber lasers generally have considerably longer life cycles and much stronger beams than other lasers and are usually far lower in price. They don’t require a vacuum, a blower or costly gas to operate. They don’t have expensive optical mirrors that have to be maintained and carefully kept in alignment. They can be used on both metals and nonmetals and are very effective in cutting reflective materials like stainless steel, copper, brass, or aluminum. They are much more efficient in converting the energy from the pump source than other types of lasers.

A Technology for the Future

First recorded in the early 1300s, the phrase “many hands make light work” remains popular today as a motivational motto in team building exercises. Taken in a much too literal sense, it did take many hands over many decades to make the light of fiber lasers work as an effective cutting tool in the world of metal fabrication.

As the 21st century progresses, fiber laser technology will continue to develop, making these metalworking marvels safer, more compact, more accurate, more inexpensive, and more efficient. The age of the fiber laser is in full swing and won’t be ending any time soon.