A Bandsaw for Every Budget

Revolution Machine Tools offers bandsaws with a range of capacities to cover nearly every project imaginable for a small, medium or even fairly large shop, and with a price range that satisfies both the hobbyist and the perfectionist alike.

The list of standard features on all of the saws is impressive, but even more so are the available options for each of the models. Naturally all of the saws feature a control panel, but some are equipped with an NC—or even CNC—control standard. Blade brushes—sometimes motorized—are standard on all models, as are coolant pumps and security switches. Hydromechanical blade tensioning comes with all saws except for those with hydraulic blade tensioning (and hydraulic is an available option with most of the rest).

Common standard features on most RMT bandsaws include Siti heavy-duty gear boxes, inverters, hydraulic vices and sensitive pressure controls. Many of the saws come standard with features like linear guide rails, optical saw height adjustment and proximity switches for sensing slippage in the blade.

The waste and mess of spilled coolant is a thing of the past thanks to some options that are available for all bandsaw models: micro-mist cooling systems for cutting thin-walled profiles and the clean, nearly dry air/oil lubrication systems developed by DROPSA. Optional hydraulic top clamping—essential in bundle cutting—is available for the majority of the bandsaw models, and many offer a laser line as an option. Optional accessories include a 10′ roller table (either regular or motorized).

How Automated Do You Want It?

As with most RMT lines of machines, the bandsaws offered by Revolution Machine Tools are separated into different series based on their characteristics; in the case of their bandsaw line, it is the level of automation.

- The S-ECO Series of manual bandsaws offer RMT quality at an affordable price. These pivot-type bandsaws are available in both single and double miter versions.

- The S-FAB Series of semi-automatic bandsaws offer straight cut, single miter and double miter in pivot and dual column designs with cutting capacities that range up to 60.2″ x 60.2″ (S-FAB C 60-60 model).

- The S-SMART Series of automatic bandsaws are available in a range of cutting capacities from 9″ up to 32″ in round stock. While most are straight-cut saws, a couple models offer single miter. The smaller S-SMART machines are pivot-type saws, while the larger models are dual column.

- The S-GENIUS Series of “super automatic” bandsaws goes a step beyond standard automation to offer a precision metal-cutting experience unheard of with most dual column straight cut saws.

Spotlight on the S-GENIUS Fully Automatic Bandsaw

Think CNC is only for press brakes and fiber lasers? Think again.

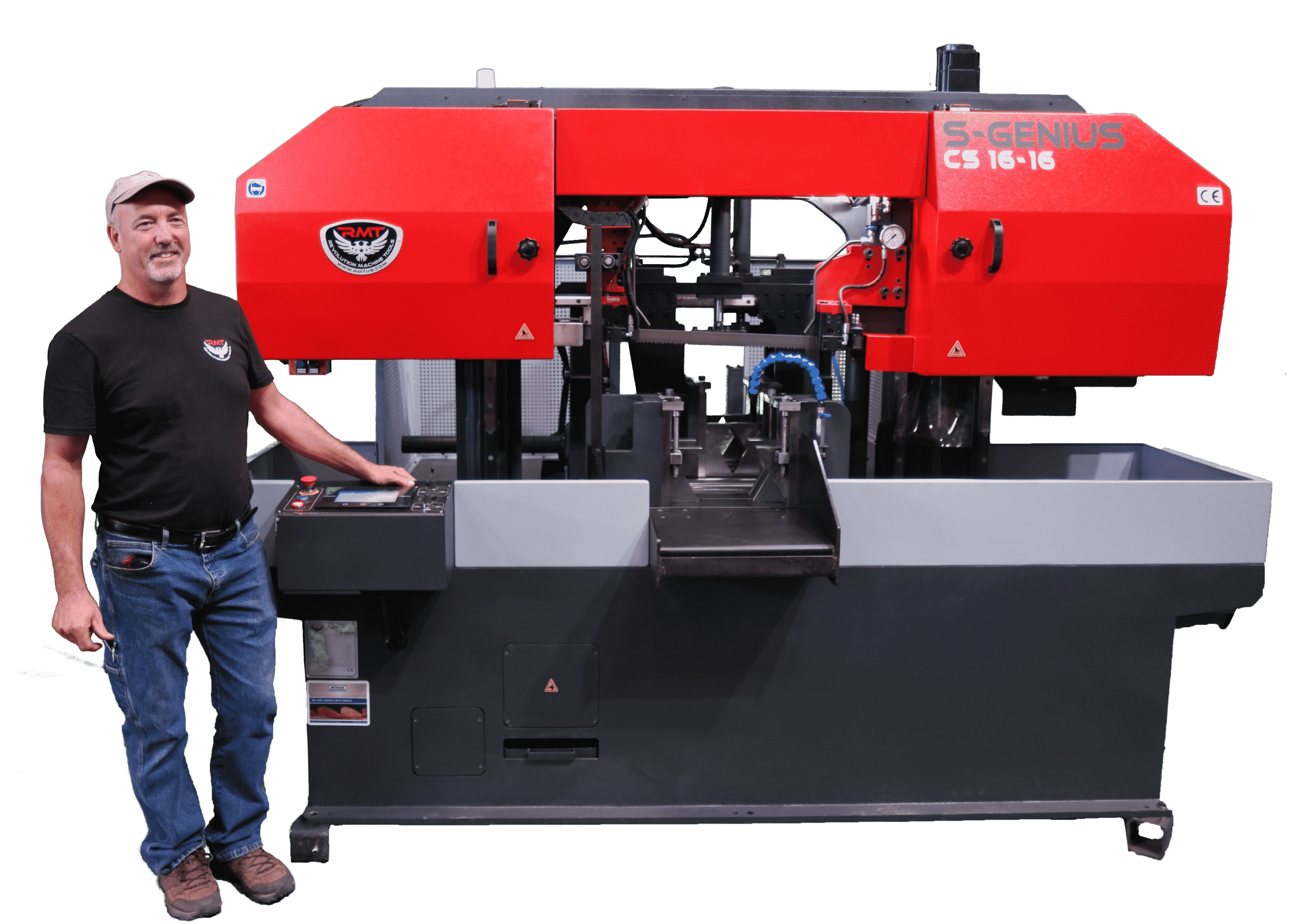

Let’s focus for a moment on the Cadillac of bandsaws, RMT’s fully automatic S-GENIUS Series. These straight cutting machines provide the operator the ultimate in metal sawing experiences thanks to their CNC-controlled servo-driven vertical blade movement.

Two saws in this series are currently available. The 7.5 HP S-GENIUS CS 16-16 features a cutting capacity of 16.5″ by 16.5″, while the 20 HP S-GENIUS CS 22-23 CNC has a flat cutting capacity of 22.4″ x 23.6″

With a fully automatic servo feeding and cutting system, the S-GENIUS Series is designed to maximize the high-volume cutting of pipes, profiles and heavy metal stock. These are ideal saws for such industries as steel production, automobile and machine manufacturing and forging mills. The life expectancy of blades can be extended by an additional 50% due to the automatic controls and sensors that maximize the performance-to-cost ratio of the S-GENIUS Series.

Spectacular cut results can be expected owing to the CNC SMART cutting feature that involves a servo motor-driven ball screw spindle. This feature offers the most efficient band saw cutting on the market by matching the type of blade to the type and dimensions of the material to calculate the ideal cutting parameters.

Other features of the S-Genius models include:

- A user-friendly touchscreen control panel

- An Omron CNC cutting program

- The ability to save up to 50 different cutting length steps in 100 different programs

- A heavy-duty planetary gearbox

- Three linear ways for vibration-free cutting

- Fast approach speed

- Optical saw height adjustment

- A servo motor-driven feeding vice with a 27″ stroke (120″ stroke optional)

- A guide arm that travels on a linear guide way and moves in coordination with the moveable vice jaw

- Hydraulically actuated carbide blade guides

- A proximity switch for sensing blade slippage

- An automatic hydraulic blade tensioner

- An automatic blade deflection sensor

- An idle wheel motion detector

- A motorized swarf brush for blade cleaning

- A motorized chip conveyor

The RMT Bandsaw Guarantee

Like every piece of equipment Revolution Machine Tools sells, their bandsaw lineup offers the same guarantees of quality and support. From a pre-sale consultation to make sure the machine is the right match for the shop and its workload to continual service until the saw reaches the end of its life expectancy—and likely a long way beyond—RMT stands by every bandsaw they sell.

RMT’s factory-trained service technicians can diagnose and resolve every issue with a customer’s bandsaw (or press brake or fiber laser) and maintenance contracts are available to help keep saws in peak operating condition and reduce the likelihood of costly surprises.

RMT’s staff of inhouse parts and tooling specialists can ship a replacement component at a moment’s notice and have all necessary blades, coolant and other high-grade consumables in-stock to keep every customer up and running.

Whether the purchase is the smallest manual bandsaw or the largest fiber laser, the team at Revolution Machine Tools are committed to their customers’ continuing success long past the sale.