A Roll by Any Other Name

“What’s in a name? That which we call a rose

By any other name would smell as sweet.”

– William Shakespeare

No other machine tool or piece of metal fabrication equipment has as many different names as does the everyday profile roll—a machine designed to put a curve into a long straight piece of metal. The simplest form of the machine is the ring roller, used by hobbyists to create rings out of metal as part of a structure to hold things like candles or potted plants.

While some will just call them rollers or roll benders, in some places they are called section rolls because they roll a section of metal that is usually going into a larger project. A very popular term for them in the US and elsewhere is angle roll, denoting their common function of rolling angle iron into curving shapes.

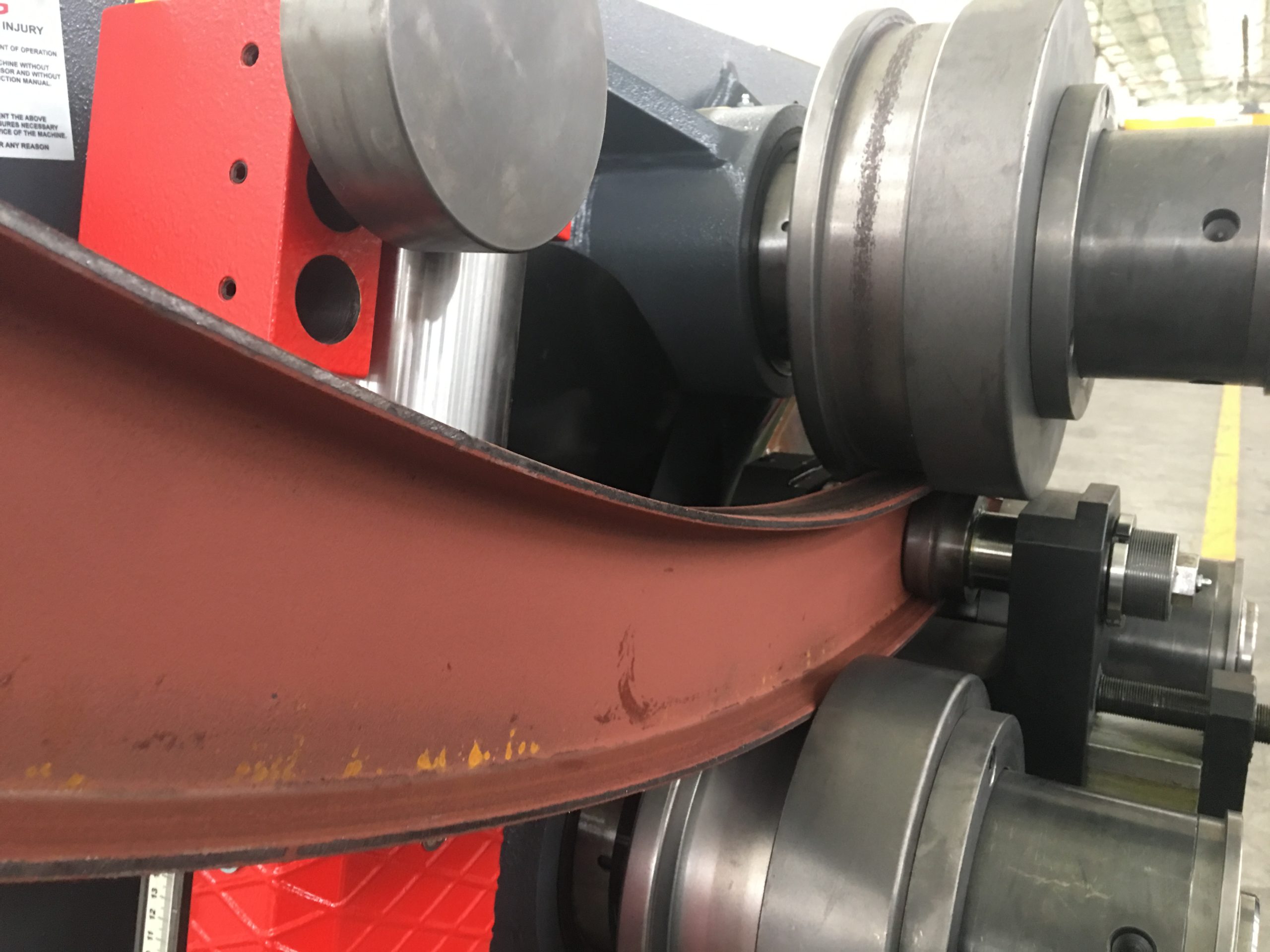

The name profile roll is more accurate, since angle iron is only one of several profiles that can be rolled with most of these machines. To look at someone or something in profile means to view it from the side, so when looking at the end of a long piece of metal a particular shape or profile can be seen, such as a circle for a tube or pipe or an L-shape for a piece of angle iron. I-beams, flat bar and square tubing are other examples of metal that all have specific profiles.

Metal with different profiles have to be held in place in the machine in different ways, so most profile rolls will have adjustable and sometimes interchangeable sets of rollers to accommodate different shaped workpieces.

What Should You Consider When Buying a Profile Roll?

Like any machine purchase, there are several factors to carefully weigh when looking at acquiring a new profile roll.

How much are you willing to spend? Budget a reasonable amount but be prepared to exceed it. You need to keep in mind that while getting a good price is important, if you don’t have the features necessary to do the jobs at hand, you will wind up spending far more in the future to make up the difference. As Henry Ford famously said, “If you need a machine and don’t buy it, then you will ultimately find that you have paid for it and don’t have it.” The same can be said for buying a cheaper machine that can’t do what you need.

What capacity do you need? You literally need to “size up” a profile roll to make sure that it is big enough to handle your largest jobs, yet capable of rolling your tightest diameters. One size doesn’t usually fit all, so you may need to consider eventually purchasing more than one profile roll, depending on your production. You will also want to get machines that have a slightly larger capacity than the biggest jobs you plan to run on them. If you frequently max out the capacity of the profile roll, you are putting unnecessary stress on it that will lead to excessive down time for repairs and a shorter machine life.

What metals do you need to roll? A profile roll that is designed to fabricate a particular size in a more malleable metal like mild steel will likely not be able to roll the same capacity in a harder, industrial-grade steel. Be sure to match your machine to your metal.

What profiles do you need to roll? Determine all the profiles that your facility could potentially roll and make sure that the machine in question is able to handle them. Each manufacturer should have one or more charts available that show which profiles can be rolled in which capacities on which of their models. It is also important to note whether your desired profiles can be done with a configuration of the current roll tooling, or if special rolls or apparatus will have to be ordered. Even though these machines are commonly marketed as “angle rolls,” they may require special tooling and side supports to properly roll angle iron.

What features will you need? Look carefully at the features and options of available machines to determine the perfect profile roll for your particular projects. Some things to consider include:

- Machine construction. How sturdy is the machine housing? Is the frame solid with post-welding stress relief? What material was used to make the roll shafts? Are the rolls ground and hardened?

- Machine power. Smaller capacity profile rolls will be motorized, but most machines are hydraulically powered. Size won’t matter if your new profile roll doesn’t have the power to perform, so confirm the power source of the machine before purchase.

- Adjustable roll positions. Smaller machines will usually have fixed position lower rolls with a moveable top roll (either manually or hydraulically adjustable). Larger hydraulic profile rolls will likely have a fixed top roll with the other rolls being adjustable for greater rolling control. Be sure to know what rolls are adjustable on the machines you consider.

- All rolls driven. Good hydraulic profile rolls will have independent power to all rolls instead of a couple drive rolls and an idle roll. This improves accuracy by reducing the chance of the workpiece slipping. See if the profile rolls you look at also offer features such as high torque drive systems and hydraulic brakes for greater strength and accuracy during rolling.

- Adjustable turning speed. Some motorized and hydraulic profile rolls will come standard with dual speed operation and may offer an option of a variable range of speeds.

- Dual horizontal/vertical operation. Small profile rolls usually operate in a vertical position, while big ones just lay down horizontally to accommodate large work pieces that would otherwise hit the ground. Many small and midsize rolls will be designed for dual operation, working vertically for most jobs but being able to be moved to a horizontal position for rolling larger diameters.

- Special apparatus. Are lateral angle guide rolls mounted on the profile rolls you are looking at? Will you want to consider mechanically or hydraulically powered lateral guides that can move to support the work piece as it is rolling (an important feature if you are bending things like spirals)? Will you need a beam pulling apparatus for better bending I-beams? Profile rolls can be equipped to bend scrolls, twist pickets and form helical stair rails, so price out the right optional equipment for your current and future projects.

- Control systems. Will digital readouts work for you, or will you want an NC control system? (Or a more specialized CNC upgrade?) Will you want a portable control unit that can be moved around to view the part from any angle during rolling?

Do you know professionals that you can consult? When buying any new piece of machinery, always talk to trusted people in the industry who have used those machines and know what to look for and avoid. They can advise you from their own experience, sharing horror stories and successes alike.

It is also important to find a machinery dealer that you can trust when it’s time to make the purchase. Do they have a solid track record and a good reputation? How long have they been in business? How long has your particular sales consultant been in the industry? Do they offer both new and used equipment? Do they take trade-ins? Do they have an in-house service staff? Do they sell parts and tooling? How are they set up to take care of you through the life of your machine?

While the technology behind profile rolls will continue to get more and more sophisticated, these machines will always remain a fixture in the metal fabrication industry. Invest in a good, high-end profile roll that will serve you for years to come and will still be worth something when you eventually trade it in on the next generation of cutting-edge metal rolling machines.