Filling a Need in Tube Laser Cutting

Brad Kalmar had been working in the machine tool and metal fabrication industry in northern Utah and observed that there were quite a few shops in the area that offered thermal cutting services—provided their customer base only needed flat metal cut, such as sheet metal and plate metal. “I was in sales, traveling back and forth, and noticed that there are probably 250 to 300 high-def plasmas, fiber lasers, and CO2 lasers from Nephi to Brigham City,” Brad said. “There were five tube lasers,” he added.

Seeing the shortage of shops with tube cutting fiber lasers in the market allowed Brad to recognize a potential opportunity. “I started looking at it, thinking, ‘Well that wouldn’t be a bad business,’” he said, deciding to go ahead and start his own laser cutting operation. He ordered the machine, had it installed, and opened the doors of Kalco Laser in January 2020 in Midvale, Utah.

The future looked bright—until the first cases of the Coronavirus reached the USA a couple of months later. “Covid was not a great year to start a business,” Brad noted. “There were complications with people trying to decide what was going to happen, what the future was going to look like, so it was a tough year, but we got through it. It was a good learning experience.”

His perseverance not only allowed him to keep the lights on during the pandemic, but to grow his business at the same time. “So far it’s been good. I just wanted to be able to offer tube laser cutting to people here in the Salt Lake area, and now we ship parts all over, to Wyoming and Colorado and places like that. It’s getting busier.”

Finding Ideal Clients

Kalco Laser is a small business—in every sense of the word. “Right now, it’s me and my son Colton. It’s just the two of us,” Brad remarked. “We’re small, low key. We have hopes of growing, but we’ve just got to grow at a rate that we can control and handle and what the market will bear.” Most of Brad’s marketing efforts have been online, with Instagram being a favorite way to reach prospective customers. “That’s how they found us,” Brad said of the bulk of his patrons.

“We’d love to cut more parts for people,” Brad commented, adding, “I’m a little picky on my clientele. I want to help people, but I want people who want to be helped, too. I mean, if I’ve got somebody that just can’t provide a 3D file, I’m not your guy. We do offer CAD service, but if you’re not willing to pay for it, I’m not your guy. If they can draw their part in some type of a CAD program and produce a STEP file/CAD file and can tab-and-notch and all of that, we can do it, so they just get their parts and they all just fit together and there’s no measuring.”

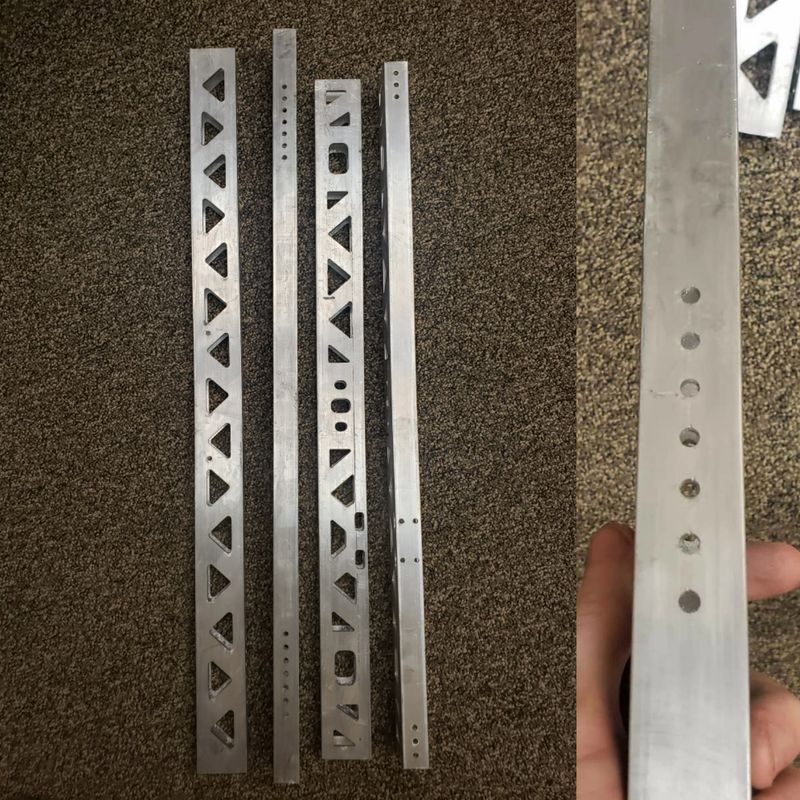

Many end users of cut metal tubing are unaware that a tube cutting fiber laser can create precise notches and tabs to easily connect mating parts during assembly, saving on the fixturing and jigging times needed after using traditional machining methods. “It’s been a learning experience trying to educate people on what a tube laser can actually do for them and how I can benefit them. I deal with a lot of people that are just set in their ways; they have a bandsaw, and they have a mill to drill their holes, but they never think about tab-and-notching and a lot of the other things that we can do to improve a customer’s part,” said Brad. “We can add features to the tube to help them put their stuff together better.”

Helping Customers Be More Productive

Customers have seen the savings in time, money, and manpower once Brad trains them to create their own CAD files with tab-and-notch programming included. “I have a customer that makes a CNC woodworking machine and all of his parts he’s designed that way,” said Brad. “He used to have a welder that would cut on the bandsaw for three days and weld for two. Now his welder welds five days a week and never touches the bandsaw—everything is cut for him, everything fits, everything is all located.”

Before Kalco lent a hand, that customer was getting behind. Brad reported that “he was developing a six month or more backlog, and when you tell somebody that it’ll be six months before they can get their machine, they just go buy a different machine. He was losing business, so they were looking to do something to produce more parts faster. His bottleneck was his plate laser and his press brake, so by redrawing his parts and having me cut everything out in tubing, he eliminated that bottleneck.”

Convincing potential customers to give his services a try isn’t always a walk in the park. “Sometimes it’s a hard sell,” Brad reflected. “I’ve got a lot of people that I go to see and ask, ‘Would you be interested in having these parts cut on a tube laser?’ and they say, ‘What am I going to do with Jimmy here, my bandsaw guy? And what am I going to do with Max, he runs the mill and drills the holes? I don’t want those guys to lose their jobs.’ I say, ‘Teach them to weld, and you’ll be better off. Everybody needs a couple of welders.’ So sometimes it’s just a hard sell.”

One customer was buying a sheet of metal that was already punched out, rolling it, then welding it together. Brad showed them how he could take a solid tube and laser cut the same part more efficiently, saving them time and money.

Brad says that his shop produces quite a few parts for the vehicle roll cage industry. He estimates that 50% of his work is for the roll cage market, about 25% doing fabrication for small shops, and another 25% producing OEM parts for manufacturers.

Getting What You Pay for

Brad became familiar with the different manufacturers of tube cutting fiber lasers before he made his purchase. “There’s a lot of guys out there selling flat lasers and tube lasers to people, Brad said. “I swear some of them do it out of their parents’ basement, and so they have no service, they have no support, they have no parts. They are glad to answer an email and say, ‘Contact this company, this is who made your machine and ask them for parts.’ They’ll do that, but there’s no service, there’s no setup, there’s no support. A lot of these guys order a machine, and it shows up, and they wonder, ‘What do I do?’ They get a machine and it’s a month-and-a-half until they get power to it, because they’re trying to figure out what power they need or find out that they need to order nitrogen for it.”

Brad continued, “People don’t realize what they’re asking for when they ask for the cheapest price. They don’t really realize, ‘Well, I’m not going to get any service, I’m not going to get any support, I’m not going to get really good software, I’m not going to get a lot of things, but I can buy this machine for this price,’ and that’s what they seem to care about. They don’t think about, ‘Yeah, but if you don’t get service and support and you have problems, what are you going to do?’ It costs them more to get somebody to come in and try and help them or they spend countless hours emailing someone in China in the middle of the night when they are awake over there.”

He contrasted those kinds of companies with Revolution Machine Tools, where he purchased his RMT KYSON T3X2210 tube cutting fiber laser. “RMT is more of a service-oriented type company where they want to take care of their customer.”

The RMT Advantage

“I decided on a tube laser and purchased one through RMT,” Brad said. “I knew RMT and their service people and salespeople and approached them about a tube laser and they said, ‘Sure, we can do it.’ I knew they sold plate lasers, but mine was the first tube laser that RMT sold.”

He loves the performance of his KYSON-series laser. “I can literally cut a tube off in less than a second where it takes maybe 15 seconds to do it on a cold saw, and there’s also a chance that there might be a burr.”

“The KYSON lasers are good lasers,” Brad said. “With the components that are put into it, it’s a good laser, there’s no doubt about it. The components in the KYSON laser are as good or better than anybody’s, definitely better than the Chinese market ones.”

Brad pointed out that many companies want to keep customers dependent on them for replacement parts and their own proprietary software. In contrast, all RMT machines use world-class components that are easily replaceable off-the-shelf from local supply houses. “You open my cabinets and I’ve got German motors and drives, a Swedish controller, software from Great Britain.”

Brad thinks RMT’s service department is top notch. “It’s tough to make satisfied customers in this industry. RMT will go and they’ll help you get your machine back up and running.” Speaking of a friend in the Pacific Northwest who also owns a fiber laser from RMT, Brad said, “He’s very happy with his machine. It’s a good machine and he has full support from a U.S.-based company. If he needs somebody up there, there will be somebody flying up there tomorrow.”

Brad also loves RMT’s parts and tooling department. “When we need to order parts, we go through RMT. They take care of us. I buy consumables from RMT on a regular basis. They’re good at what they do.”

Due to his positive relationship with Revolution Machine Tools, Brad has happily cut parts for them from time to time. “Because of their willingness to provide such a good product for me, I’m willing to help them do test parts for customers,” he said. He regularly does R&D projects for RMT.

Brad said he recommends Revolution Machine Tools to anyone wanting to buy either a flat or tube fiber laser. “RMT’s been good as far as supporting me and helping me. I think they do a good job. They make good equipment. They try and help their customers with their needs. They’re a good partner if you’re going to get into the business.”

Brad noted that with some of the bigger laser producers—whose machines cost twice as much but aren’t any better—customers are just a number to them. “With RMT, when you’re a customer, you’re a partner,” Brad said.

He plans to keep partnering with them well into the future as he continues to grow his business.