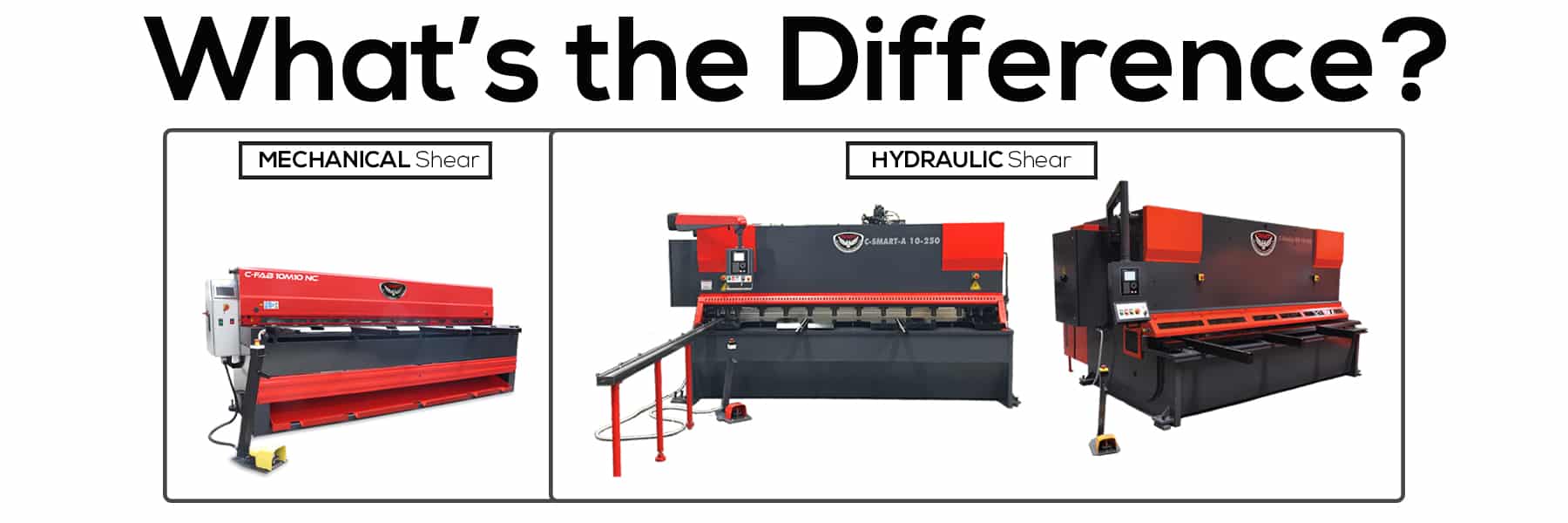

Which Shear Is the Best?

You are considering purchasing a new plate cutting shear for your metal fabrication shop and wonder which shear is the best—mechanical vs hydraulic shear? The answer is a confusing but simple “Yes.”

Asking which shear is better is like asking whether a mechanic or a doctor is better. You might be quick to answer, “a doctor,” because of his advanced schooling, but if your car is broken down in the middle of the desert, having a mechanic on hand would probably be the correct solution for your situation. The same logic applies to shears, or any other metalworking equipment—you get the one that takes care of the problems at hand.

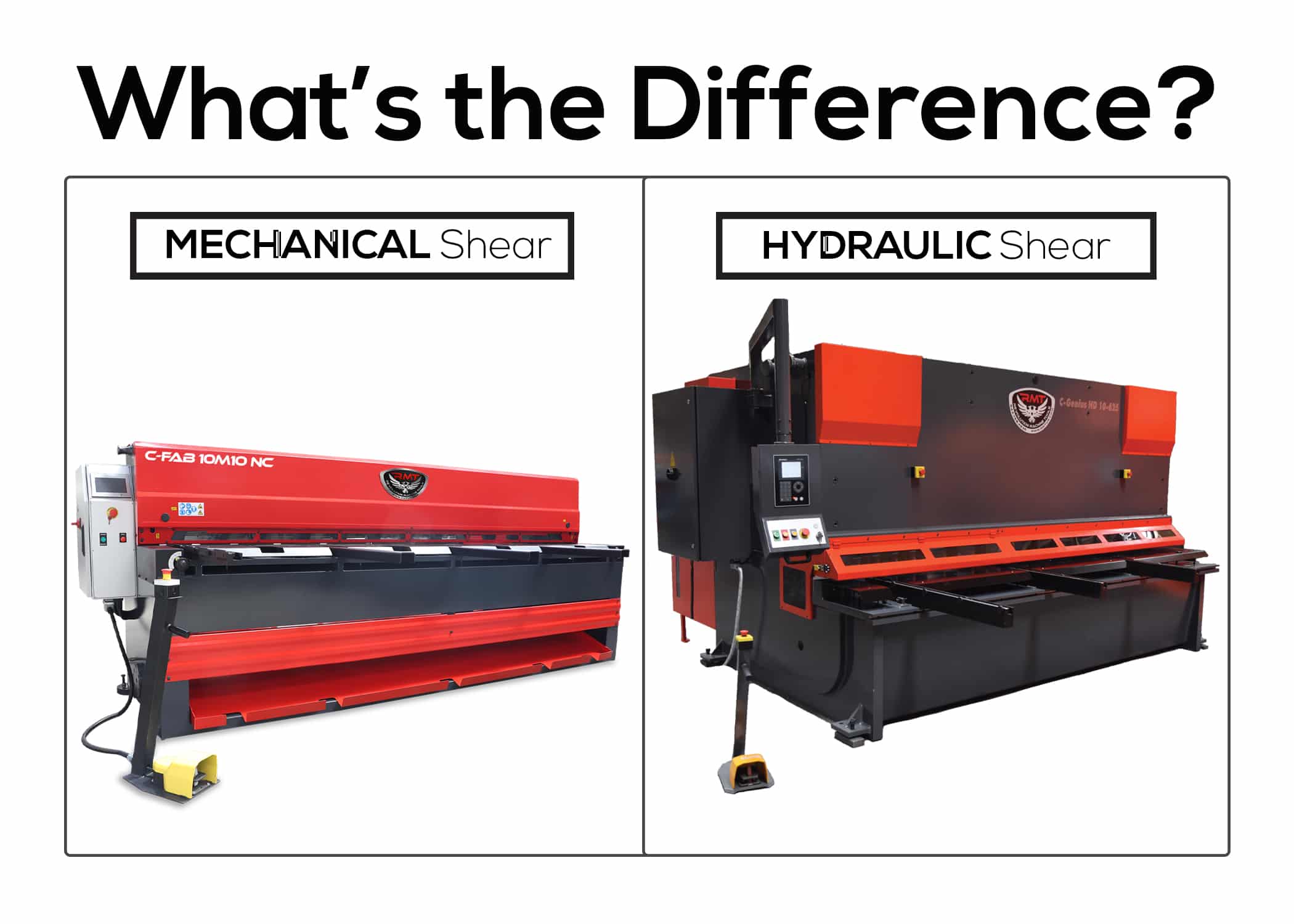

The difference between the two shears is in their mode of transmission—a mechanical transmission versus a hydraulic transmission. In fact, a better analogy might be looking at the differences between automobiles with manual and automatic transmissions—each has advantages and disadvantages compared to the other, so it really comes down to a matter of preference. The shear buyer also must look at the benefits and drawbacks of each type of machine and make an educated guess as to which will work best for their upcoming projects.

Advantages of Mechanical Shears

While the working noise of mechanical shears is incredibly loud, overall, they are quieter as they don’t have the constant noise generated from a continually running hydraulic system. In full-cycle mode they cut more rapidly through metal than hydraulic shears, so if you don’t need to shear anything thicker than 1/4″ plate and won’t be needing to run the shear all day long, a mechanical shear might be your best choice.

Other benefits of mechanical shears include:

- Cooler | Hydraulics run hot and require cooling, something that isn’t a problem with mechanical shears. This also means they don’t waste as much energy.

- Greener | If you want to be more environmentally friendly (and project that image to your customers), mechanical shears don’t require any hydraulic oil, and therefore they don’t produce any hydraulic waste in the form of oil or filters.

- Simpler | Mechanical shears have simpler mechanisms to learn, operate and maintain.

- Sturdier | The robust construction of mechanical shears with their heavy frames and castings makes them more shock resistant than shears with hydraulic cylinders. Mechanical shears can better absorb the jolts that comes during the shearing process.

Advantages of Hydraulic Shears

While its working speed is slower than a mechanical shear, a hydraulic shear can be continuously operated, making it perfect for high production facilities (mechanical shears need to rest between batches of cutting). They are also usually more compact than their mechanical equivalents, saving shop space.

Other beneficial aspects of hydraulic shears include:

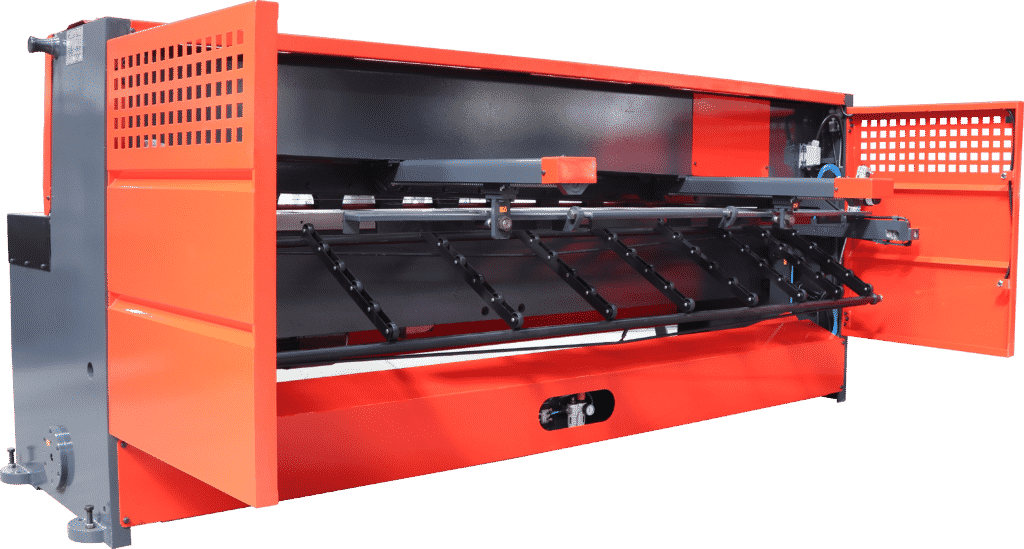

- Accuracy | Hydraulic shears are extremely precise machines with greater accuracy than most mechanical shears. In addition, many hydraulic shears provide for precise adjustments, such as an adjustable rake angle for cutting thinner materials with less twist, or a variable stroke length, which is helpful when short strokes are needed for shearing very narrow material (unlike mechanical shears, which must make a full cycle when cutting). The blade clearance on hydraulic shears can also usually be adjusted very quickly and easily, an improvement over the more difficult and time-consuming process for mechanical shears.

- Capacity | While a mechanical shear can deliver a very fast, powerful downstroke, the cylinders on a hydraulic shear can generate a large amount of pressure, allowing thicker plates—specifically those ranging from 3/8″ to 1″—to be easily sheared, depending on the model of machine. Hydraulic shears are also the better option for longer workpieces.

- Operation | Hydraulic shears, while more complicated, are designed in a way that allows a trained operator to run and maintain them with ease. Their operation is much smoother than mechanical shears.

- Safety | While mechanical shears can be stopped in a cycled downstroke in case of a hand or other object crossing into the cutting zone, hydraulic shears can be set to automatically reverse when stopped. Coupled with a light curtain, hydraulic hold downs and proper guarding, hydraulic shears can be considered safer than mechanical ones. In addition, hydraulic shears are usually equipped with hydraulic overload protection to reduce damage to the machine itself when encountering an obstruction or an oversized workpiece or an overly hard material. If the maximum PSI is reached, a safety valve releases, stopping the shearing action.

Final Considerations

Both mechanical and hydraulic versions have benefits to consider when choosing a new shear for your shop. While the growing trend is to buy hydraulic, all aspects of both types should be weighed carefully. Future expansion should be considered alongside the types of jobs you are currently bidding.

Once you have decided on the type of transmission mode, there are other factors to look at as well. For example, if you’ve decided to purchase a hydraulic shear, will you want to get a swing beam shear or a guillotine shear? Will you want a shear with variable rake adjustment? Do you need a CNC control panel? What sort of material supports will you want to have? Make sure you do extensive research and be sure to consult with an experienced machinery adviser who has your best interests at heart before you commit to a decision.

Regardless of the type of shear you purchase, ensure that you have properly trained personnel on staff to operate and maintain it. Like all tools, a powered metal shear is only as good as the people running it, so spare no expense in training or hiring the right operators and service techs.

Every shop needs a good shear, and the purchase of a quality shear will improve productivity and enhance your bottom line, so find the right one that can grow with your operation over the next several years.