Give it to Me Straight

When the band saw was invented, craftsmen were excited to have a tool that could deftly cut through wood—and later metal—so readily. Any time a workpiece needed to be severed at a specific point, the shop’s bandsaw could be powered up to make the cut. Provided it was a straight cut, that is. Workers in wood and metal found they needed quite often to make a 45° cut in their material to form corners for framing work, so bandsaw manufacturers rose to the occasion and created bandsaws that could miter to one or more degrees to fit the bill.

One might assume that the dawn of the mitering metal bandsaw would also be the death knell of the straight cut saw—after all, miter saws also make 90° cuts, so wouldn’t all metalworkers prefer to own a saw that could do it all? Apparently not, since there continues to be a steady stream of straight cutting bandsaws being sold, despite all the single and double miter saws flooding the market.

Advantage of a Straight Cut Bandsaw Over a Miter Bandsaw

For the shop that doesn’t require anything other than a 90° cut, the benefits of buying a non-mitering bandsaw are threefold:

- Lower Cost

- Greater Stability

- More Compact Machine

To add an angle-cutting feature to a bandsaw costs money, and while it might not be that much of an increase to its price tag to allow a small 9″ or 12″ saw to miter, the investment for that option grows proportionately with the size of the saw that is being manufactured.

Mitering means moving. Having a major section of a bandsaw that can be repositioned to different locations around the frame or base of the machine introduces potential compromise to its overall stability. No matter how securely the head or base can be locked into position, it’s still not as solid as a reinforced and stress-reduced weld would be. Vibrations—and bandsaws make plenty of those—can still work things loose.

Additional components are required for a mitering option, increasing the size and weight of the bandsaw. Multi-angle bandsaws require a larger footprint to miter cut and often take up more floor space than their non-miter counterparts, even if they are never changed from their “home” position. One might not think about a giant 20′ long x 8′ wide bandsaw in terms of being “compact,” but adding more size and weight to such a machine when it isn’t needed is fundamentally wasteful.

A business like a steel service center that only makes 90° cuts in 60″ round or square stock, or does bundle cutting in large volumes, needs as stable a bandsaw as possible, preferably one without unnecessary cost, size, or weight.

Straight Cut Bandsaws from RMT

Many metal fabricators do require miter cutting capabilities. That’s why here at Revolution Machine Tools we offer well over a dozen different types of single and double miter bandsaws to supply their needs. Still, we would never dream of neglecting our customers who want automatic and semi-automatic straight cut bandsaws. That’s why we offer the following RMT saws that range from 9″ to 60″ in cutting capacities:

- 9″ S-SMART P 9-9 Automatic Pivot Type Straight Cutting Bandsaw | Cutting capacity of 9″ round or square; 9″ x 9.4″ rectangle

- 12″ S-SMART P 11-12 Automatic Pivot Type Straight Cutting Bandsaw | Cutting capacity of 12.6″ round; 11.8″ square; 11.8″ x 12.6″ rectangle

- 13″ S-SMART CS 13-14 NC Automatic Column Type Straight Cutting Bandsaw | Cutting capacity of 13″ round or square; 13″ x 14″ rectangle

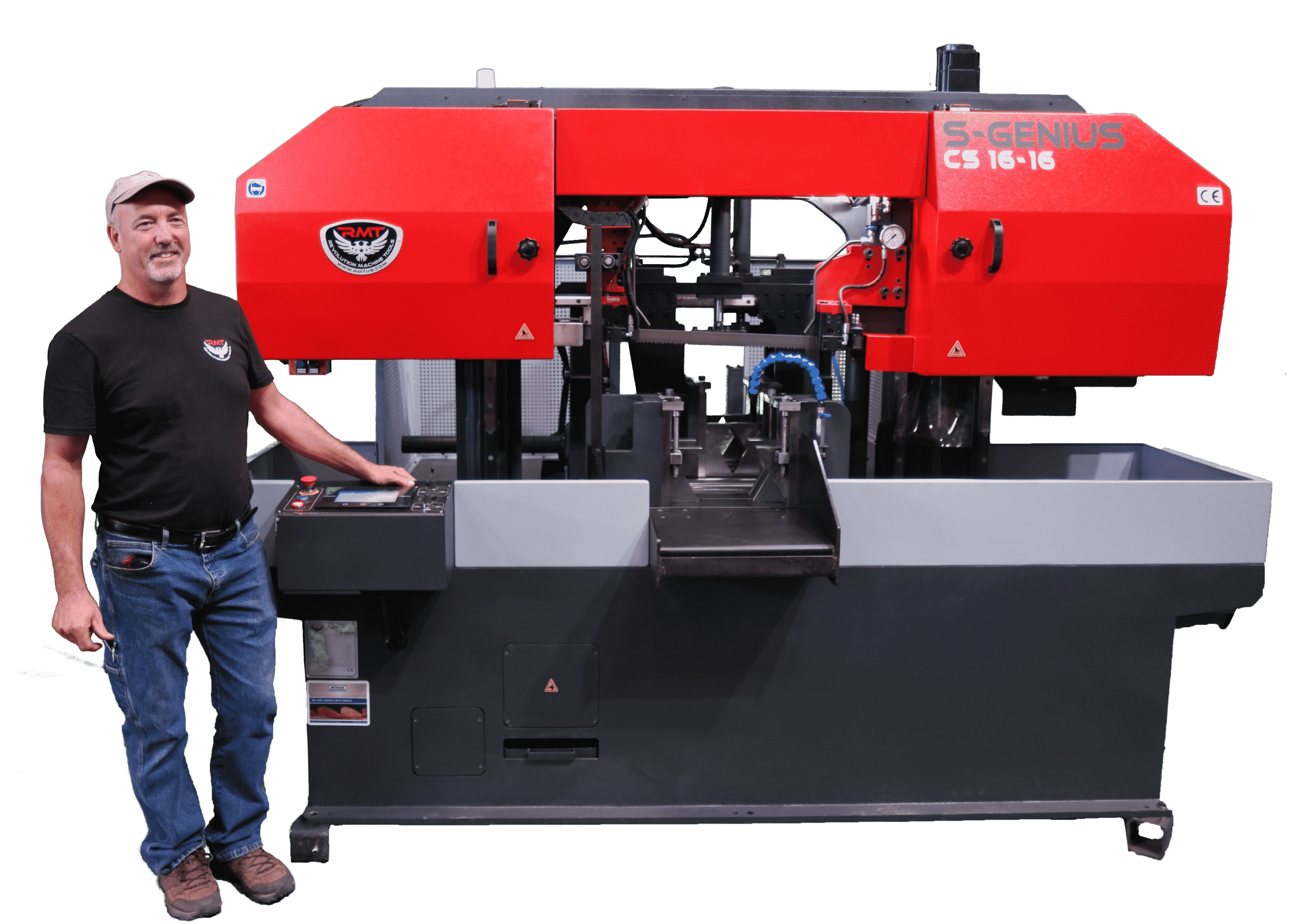

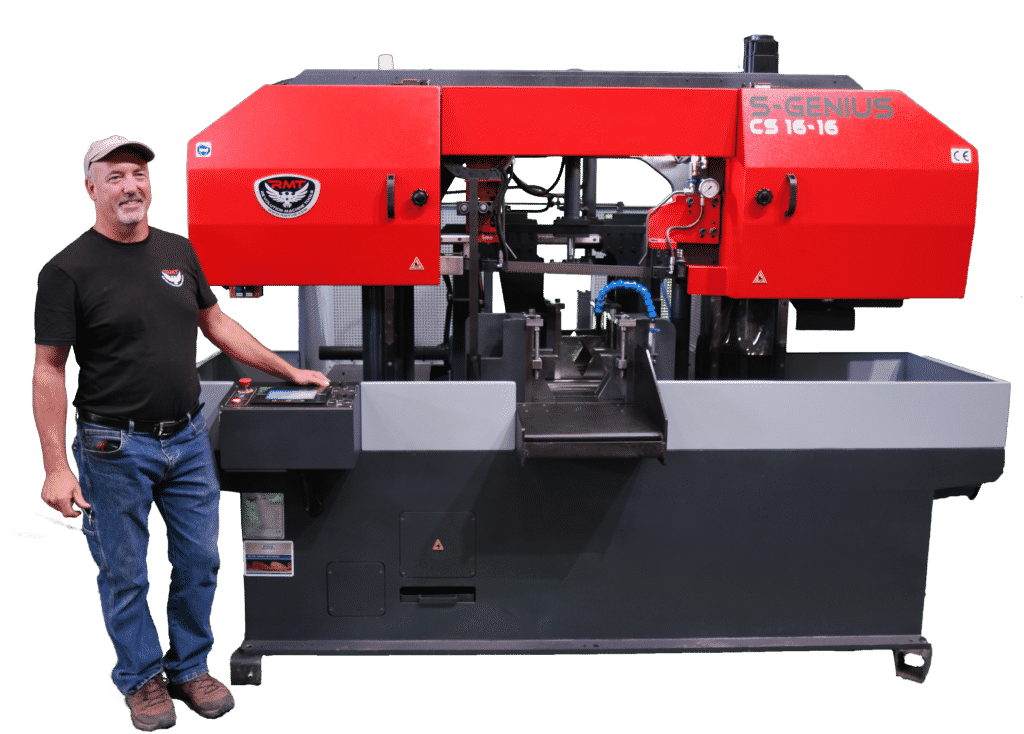

- 16″ S-GENIUS CS 16-16 Fully Automatic Servo Column Type Straight Cutting Bandsaw | Cutting capacity of 16.5″ round or square; 16.5″ x 16.5″ rectangle

- 18″ S-SMART C 18-24 Automatic Column Type Straight Cutting Bandsaw | Cutting capacity of 18.1″ round or square; 18.1″ x 24″ rectangle

- 22″ S-SMART C 22-26 Automatic Column Type Straight Cutting Bandsaw | Cutting capacity of 22″ round or square; 22″ x 26.4″ rectangle

- 22″ S-GENIUS CS 22-23 CNC Fully Automatic, Servo Column Type Straight Cutting Bandsaw | Cutting capacity of 22.4″ round or square; 22.4″ x 23.6″ rectangle

- 26″ S-SMART CS 24-42 Automatic Column Type Straight Cutting Bandsaw | Cutting capacity of 26″ round; 24″ square; 24″ x 42″ rectangle

- 32″ S-SMART CS 31-33 Automatic Column Type Straight Cutting Bandsaw | Cutting capacity of 32″ round or square; 31″ x 33″ rectangle

- 40″ S-FAB C 40-40 Semiautomatic Column Type Bandsaw | Cutting capacity of 40.2″ round or square; 40.2″ x 40.2″ rectangle

- 43″ S-FAB C 43-90 Semiautomatic Column Type Bandsaw | Cutting capacity of 43.3″ round or square; 43.3″ x 90.5″ rectangle

- 51″ S-FAB C 51-51 Semiautomatic Column Type Bandsaw | Cutting capacity of 51.2″ round or square; 51.2″ x 51.2″ rectangle

- 60″ S-FAB C 60-60 Semiautomatic Column Type Bandsaw | Cutting capacity of 60.2″ round or square; 60.2″ x 60.2″ rectangle

Setting the Record Straight

Buying a machine with all the optional bells and whistles can be fun, but often isn’t practical. This applies especially with a metal service center or other metalworking facility that just needs to cut down longer stock all day long. Owning a bandsaw that can angle cut and do other tricks is fine, but it’s likely a waste of money to upgrade to a feature that isn’t practical and may never be used. Simply put, if a shop or other business doesn’t need to miter cut, it doesn’t need a miter cutting bandsaw.

Before you invest in your next straight cutting bandsaw or other significant metal fabrication machine, please be sure to give Revolution Machine Tools a call for a competitive quote, along with an expert evaluation of what your facility will require for your projected future metalworking projects.