Fly Me to the Moon

If you were ever to overhear someone saying that Kyle Jorgenson has his head in the clouds, you shouldn’t jump to the conclusion that they mean it in a bad way. Perhaps it started when he was serving in the U.S. Army as a helicopter mechanic, but the founder of Revolution Machine Tools has long expressed a fascination with aerospace vehicles that soar into the heavens.

When his military service concluded, Kyle rejoined his family’s industrial equipment company where he had worked since he was in grade school. After becoming the head of the machine tool division upon his father’s retirement, Kyle led the team that developed a custom plate roll for a major aerospace firm to use in producing better booster rockets.

Upon starting Revolution Machine Tools, Kyle continued to keep an eye to the sky, spearheading a lineup of high-tech machines ideal for use in the aerospace industry, including RMT’s own specialized rocket fuel tank bending roll.

Rolling Out Aircraft

Boxes don’t tend to be very aerodynamic, which is why aircraft are generally cylindrical in shape. Even though a press brake can be used to create curving shapes through multistep bump-bending processes, most airplane and jet manufacturers prefer to use plate rolls to craft fuselage panels and single-piece cylinders.

Revolution Machine Tools knows a thing or two about plate rolling machines—they offer nearly 90 standard models of hydraulic plate rolls, not to mention motorized slip rolls—so it shouldn’t come as a surprise that their R&D department has worked on cultivating specialized and customized rolls targeted at the needs of specific industries. Whether a customer wants to manufacture traffic barriers, tanker trucks, wind towers, or rocket ships, RMT can provide the machine to do the job.

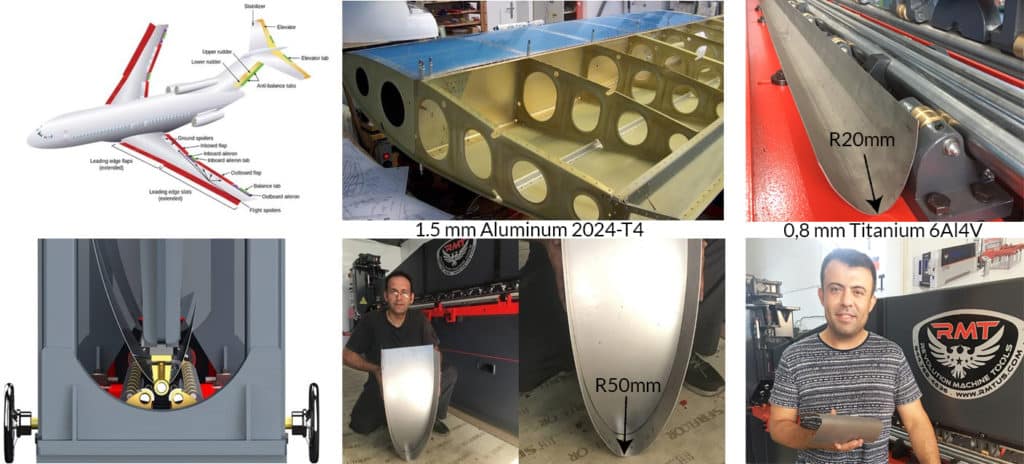

One such significant development is RMT’s isogrid and orthogrid forming technology. Two critical characteristics of aeronautic fuselage components is that they must be both strong and lightweight, an often-contradictory proposition. To solve this dilemma, a waffle-like structure was conceived by aerospace engineers in the middle of the 20th century that would consist of a smooth metallic skin reinforced by stiffened ribs on one side. The original style with triangular pockets is called isogrid, which is stronger, while a pattern of square or rectangular cavities is called orthogrid, which is lighter. Usually milled from a single sheet of a lightweight metal like titanium or an aluminum-lithium alloy, cold spray additive manufacturing techniques have begun to be utilized in some sectors for less material waste during production.

Once an isogrid or orthogrid plate has been manufactured, there remains the task of shaping it to the correct radius for the specific fuselage being assembled, a difficult and time-consuming process. Traditional plate rolls are generally not up to the task of bending these inch-and-a-half thick panels, and the ones that can do so often cause deformities in the structure due to improper crowning. The usual forming method is step-bending the panels on a press brake, but an average aerospace panel can require over 500 steps, and even then, deformations will often occur that need to be painstakingly corrected.

Enter RMT’s R&D engineers, who are finding ways to solve these issues with new bending methods utilizing specialized rolling machines and automation systems. Dynamic crowning that maintains the proper pressure at every point along the bending length minimizes deformations, while a reverse bending feature can readily correct any accidental over-bending. Combining the sensitivity and repeatability of CNC press brake bending with the speed and evenness found in continuous plate roll forming, RMT’s isogrid and orthogrid forming machines meet the challenges of 21st century aerospace manufacturing head on.

Just Winging It

Innovations in manufacturing usually have a pressing need in their industry driving them. Such was the case as the great depression was nearing its end and the United States was looking at the probability of being drawn into the war in Europe. Both the U.S. Army Air Corps (predecessor of today’s United States Air Force) and the civilian aeronautics sector were looking to create aircraft at an unprecedented rate. The nearly fifty-year-old Farnham Manufacturing Company—best known at the time for producing machines used in paper mills—experimented over several years to create and refine a specialized rolling machine that could form the complex curvatures found in the leading edge of aircraft wings.

Introduced in 1940, more than four-dozen Farnham leading-edge forming rolls could be found in the facilities of 21 major aircraft manufacturers by April of the next year. By the time the U.S. entered World War II at the end of 1941, Farnham rolls were being produced at a breakneck rate, a pace that only increased throughout the war. As all good things tend to do, the Farnham company eventually came to an end. Following the war, a series of buyouts and mergers began that would leave the company little more than a footnote in the aeronautical history books by the mid-1980s.

The legacy of the Farnham aircraft rolls remained, however, and original Farnham machines are still in high demand in the market today, though they are becoming sparce as the years pass. During his experience in the metalworking equipment industry over the years, Kyle Jorgenson saw firsthand how used Farnham rolls would virtually fly off sellers’ floors once they were put in stock. Once he had started Revolution Machine Tools, Kyle put his R&D team to work providing a much-needed solution to fill the void left by the classic wing-making machines. “We decided to bring them back,” the RMT founder said. “We have some customers that need them. It’s really hard to find used [Farnham] machines, especially in good condition.”

RMT’s F-FAB Series of aircraft rolls feature more than a dozen models of machines that can form the leading edges of aircraft wings as well as other contoured and tapered parts. RMT also offers their F-SMART Series of rolls equipped with portable NC control units for even better repeatability during production. Specially designed to overcome the high yield point of materials such as titanium, RMT’s aircraft rolls offer the best speed and precision available today in aviation fabrication.

Take Flight with RMT

From the literal cutting-edge technology of their KYSON fiber lasers to CNC press brakes that feature some of the best accuracy and repeatability in the business, Revolution Machine Tools offers world-class metal fabrication tools that can produce the most precise parts in the industry. Whatever component you need shaped from metal, RMT machines will match or exceed the competition.

If you are in the business of building craft that “have slipped the surly bonds of Earth and danced the skies on laughter-silvered wings,” then give RMT a call today and chat with one of their machinery consultants about your upcoming projects. Allow Revolution Machine Tools to show you better solutions for your aerospace manufacturing needs.