Why buy a plate roll from Revolution Machine Tools instead of those offered by the competition? The answer is easily summed up in three words: Quality, Variety, Service.

RMT Means Quality

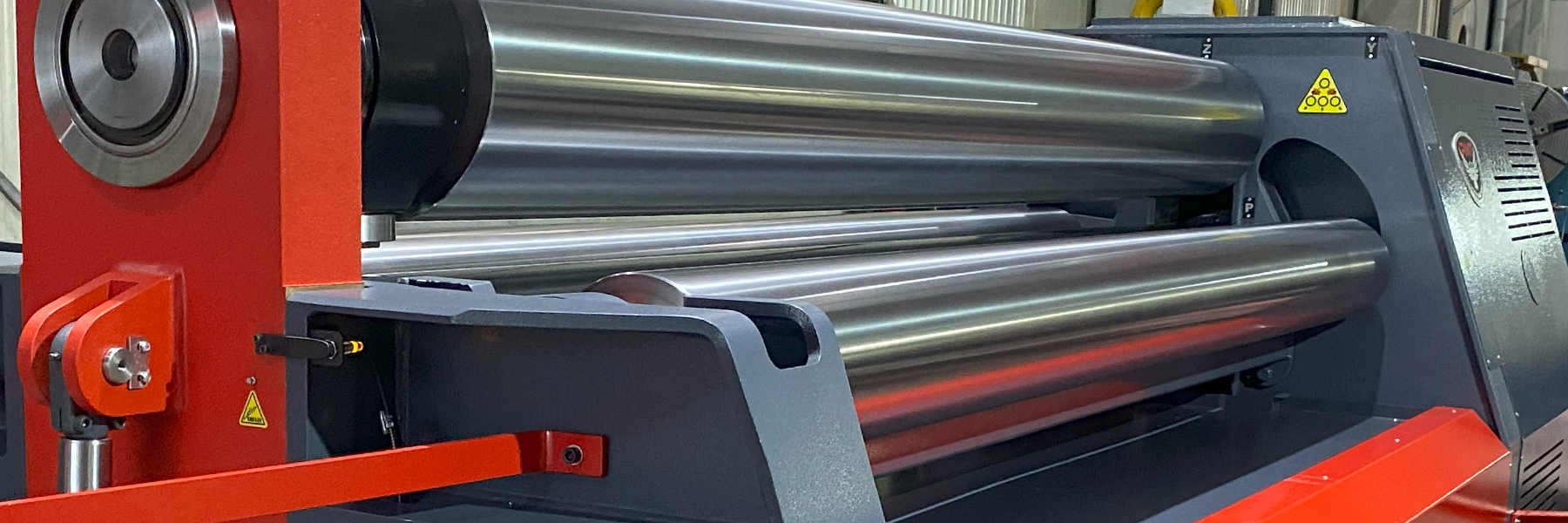

Plate bending machines sold by Revolution Machine Tools have been designed from the ground up by veteran engineers. They incorporate the best materials available into machines built with an eye to functionality. The state-of-the-art technologies perfected by RMT Research and Development teams result in cutting edge plate rolls that deliver unparalleled accuracy and industry-leading precision.

RMT plate rolls are highly efficient machines designed to offer the end user the most seamless manufacturing experience imaginable. Power and speed don’t take second place to safety, however, with these rolls offering built-in safeguards that match or exceed industry standards, such as their pressure safety valves.

Most RMT plate rolling machines come standard with specially designed high-tensile forged steel rolls with larger diameters for greater strength. Crowning compensation is machined in by high-precision CNC lathes to prevent the deformation that often occurs during the pre-bending process with most other rolls on the market. The rolls also feature working surfaces that are induction hardened to HRC 54-58, allowing for the tightest diameter rolling available.

The 4-roll machines offered by RMT are hydraulically powered and use high-speed response Parker valves to maintain precision. The electrical systems are built with world-renown components like Siemens, Schneider, Phoenix and Opkon. These high-quality components not only last longer, but if they do eventually go out, replacements are readily available off-the-shelf at local suppliers, reducing machine downtime.

RMT plate rolls can be custom-built for specific project requirements, and standard machines have a fleet of available options that make them extremely adaptable. Some of these options include:

- Side and overhead supports to help prevent distortion in large cylinder bending.

- Cartesian-type overhead supports for forming rectangular tanks.

- Dual knuckle side supports for custom applications.

- Gas shock absorbers to prevent welded work pieces from damaging rolls.

- NC and CNC controls.

- Variable speeds.

- Oil coolers and heaters.

- Wired or wireless remotes.

- Automation systems.

- Automatic central lubrication.

- Changeable top rolls for smaller diameters.

- Special roll crowning.

- Material handling options.

RMT Means Variety

Some manufacturers may boast that they have a metal roller for every need, but Revolution Machine Tools can actually stand behind such a claim. From small sheet metal shops needing a quality slip roll to aircraft manufacturers needing specialized equipment to grain silo producers needing incredibly huge machinery, RMT offers rolls to meet almost any requirement.

The RMT R-ECO Series are economical initial pinch rolls that are designed for bending small parts. These reliable machines feature sturdy frames, powerful chain and gearbox drive systems foot pedal controls, safety features, and are powered by electric motors designed to eliminate drift. They are available in lengths up to 10′ and capacities up to 3/8″.

The RMT R-FAB Series are robust initial pinch 3-roll machines ideal for shops needing to produce small to medium parts. Built to last, these hydraulically powered rolls are designed to help keep operating costs low. The R-FAB Series are available in lengths up to 10′ and capacities up to 1/2″.

The R-SMART Series are the standard 4-roll plate rolls offered by RMT, but there is nothing ordinary about them. These hydraulic workhorse rolls were specially designed to meet the requirements of the most demanding applications, and to do so at production speeds unknown previously in the industry. The rolls move in a planetary configuration—the side rolls move in arcs up towards the top roll—and machines are available up to 13′ long with capacities up to 5/8″.

The RMT R-GENIUS Series of 4-roll plate rolls go beyond the mark in offering extreme precision for fabricators that need it and are fully CNC equipped. The crown jewels of RMT’s plate roll line, R-GENIUS hydraulic plate rolls are the culmination of decades of machine-building experience. The rolls move in a rectilinear configuration—the side rolls move in straight lines towards the top roll—and models are available up to 20′ long with capacities up to 3-3/8″.

The R-HYBRID Series are RMT’s entry in the variable-geometry plate roll market. These 3-roll machines feature bottom rolls that move horizontally in relation to the center of the machine, changing the geometry of how the rolls operate depending on the job. A wider stance on the bottom rolls allows heavier plate to be rolled with less crowning deformation due to deflection, while a narrower position permits thinner material to be rolled to a tighter diameter. The bottom rolls act like a variable V-die in a press brake—with the top roll acting like a press brake ram—making this a truly hybrid piece of metal fabrication technology. Suitable for medium and thick plate bending, the R-HYBRID Series is available in lengths up to 13′ with capacities up to 2-3/8″.

RMT’s F-FAB Series are designed for fabricators needing multiple radius bending, like manufacturers in the aerospace industry that produce aircraft wings, helicopter propellers and fuselage panels. These motorized variable-geometry 3-roll machines bend aluminum, sheet metal and even ultra-high yield point titanium-alloyed sheets to the required cylindrical, tapered or hyperbolic shapes. Available up to 20′ in length with capacities up to 12 gauge in 6242 titanium, F-FAB aircraft rolls can also be custom-designed by RMT’s R&D teams for specific customer projects.

The F-SMART Series are numeric-controlled, servo-driven variable-geometry rolls designed for aircraft fabricators requiring extreme precision. RMT’s portable NC control unit moves with the operator to allow them to monitor the forming process anywhere in the work area.

Besides the standard rolling machines listed above, Revolution Machine Tools has also developed many unique, custom solutions for aerospace and other key industries, including the following types of plate roll systems:

- Automatic Liquid Tank Bending Lines

- Automatic Vertical Coil-feeding, Edge-cutting, Bending and Welding Systems

- Corrugated Sheet Bending Machines

- Isogrid & Orthogrid Panel Rolling Machines

- Pipe Bending Rolls

- Space Rocket Fuel Tank Roll Benders

- Traffic Barrier Bending Rolls

- Vertical Bending Solutions for Silos and Vertical Tanks

- Wind Tower Bending Lines

RMT Means Service

Revolution Machine Tools stands behind every machine sold, providing outstanding service even before the sale, and continuing to do so until the equipment is eventually retired after a long life.

Before an RMT sales representative even begins discussing possible plate rolls, he or she will make an on-site assessment of the customer’s production floor to determine what equipment to recommend based on layout, material handling needs and machine rigging requirements. RMT can verify adequate electrical, pneumatic or hydraulic requirements and will assess if surrounding equipment could cause any electro-magnetic or vibrational interference. RMT will also offer to install and test the plate roll, if the customer wishes.

RMT maintains a team of expert full-time service technicians to assist customers—and even non-customers—with repairs, scheduled maintenance and machine upgrades. The service team stands ready around the clock every day of the year to keep RMT machines running at peak efficiency, and customized preventative maintenance plans can be implemented to extend the life of every machine and avoid downtime.

Revolution Machine Tools also has a stocked Parts and Tooling Department onsite with trained specialists who can provide the highest grade of tooling, consumables, accessories and repair parts to make any brand of fabrication equipment or machine tool run even better than they were originally intended to do.

Above all, once a customer establishes a relationship with RMT, they’ve got a friend for life in the industry who will have their back and make sure they get the right machines for the right jobs at the right price, each and every time.

For a variety of quality, supported plate rolls that will fulfill all your production goals and needs, please give Revolution Machine Tools a call today!