Tube Cutting Methods

Metal pipes have been around a long time, with iron pipes crafted in ancient China and lead pipes in use in the Roman Empire. The basis for modern pipe making was developed in the 19th century, with methods for forming seamed pipes and tubes coming about in the early 1800s and for seamless pipes in the latter part of that century.

While pipes and tubes were originally created for use in the transport of liquids and gases, both round and square tubular steel was discovered to be useful as a lightweight, sturdy structural component. With higher demand for metal tubing in construction and ornamental work, more and more technologies have been brought to bear over the years for cutting and decorating tubes.

Traditional equipment for cutting metal tubes include:

- Manual pipe and tubing cutters that are rotated around a workpiece.

- Hacksaws and reciprocating saws.

- Rotary abrasive saws.

- Bandsaws.

- Cold saws.

- Shears.

- Lathes.

Methods for putting holes and other shapes into tubes for functional or decorative purposes include:

- Tube punching (using a punch with a mandrel-supported die).

- Tube piercing (using just a punch to make a dimpled hole).

- Drilling.

- Milling.

- Tube notching.

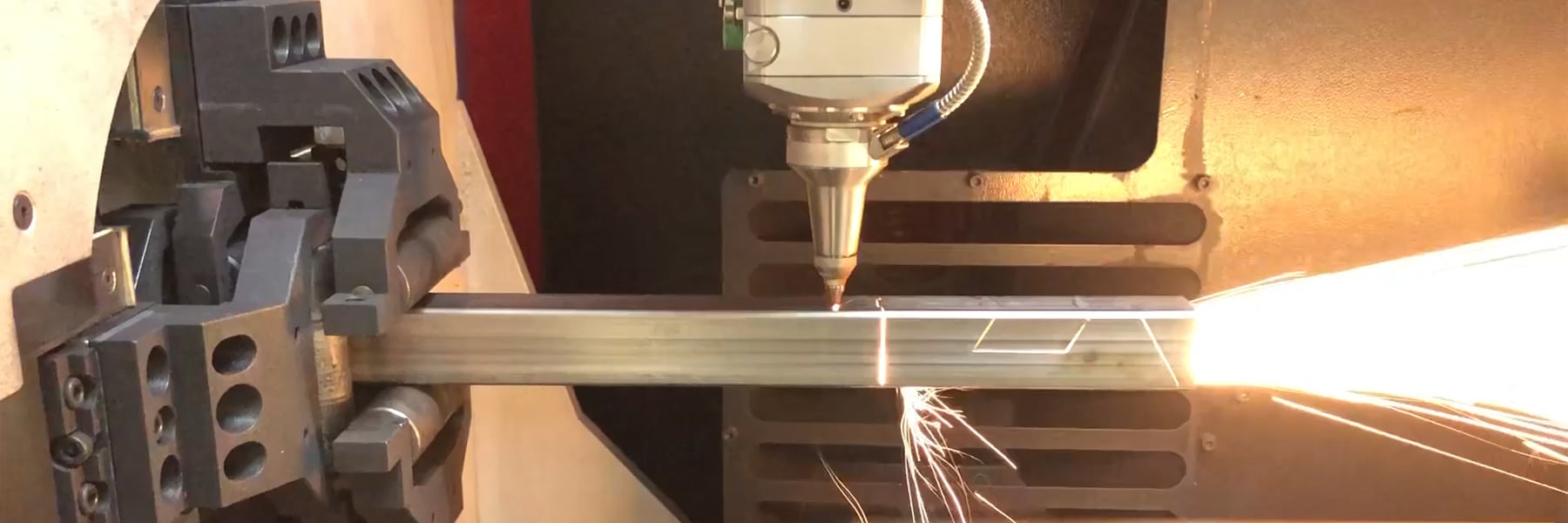

With the advent of plasma cutting, the custom cutting and crafting of metal tubes was tremendously advanced. Then along came metal-cutting lasers, and the science of tube fabrication took a giant leap forward.

Tube cutting fiber lasers are the latest innovation in the field, effectively replacing saws, drills, mills, notchers, and punches for the processing of metal tubing of all varieties.

Why a Fiber Laser Is the Best Choice for Tube Cutting

Some fabricators might tend to shy away from tube cutting fiber lasers because of the price tag, but these highly efficient machines provide an incredible return on investment for their owners. Here are some of the benefits that using a fiber laser for pipe and tube cutting offers:

- Precise Cutting. Tube processed with a fiber laser is cut far more accurately than with other methods, due both to the size of the cutting “tool” (a laser beam) and the minute positioning provided by the CNC system.

- Better Edge Quality. Little to no secondary operation is required with fiber laser cutting. The edges are smooth, and the little slag that’s created is a far cry from the burrs left behind from traditional cutting and punching. Parts come off the laser ready to be assembled.

- Low Thermal Deformation. Unlike cutting with plasma, fiber laser cutting leaves a very small heat-affected zone (HAZ) with almost no thermal deformation of the metal.

- No Stress-Weakening of the Metal. The laser head never makes direct contact with the material, unlike traditional cutting methods that physically impact the metal and weaken the material around the cut through mechanical stress and vibrations.

- High Repeatability. With the precise laser beam controlled by the CNC system, processes can be repeated accurately on subsequent work pieces. This is very important for both small batch processing as well as mass production of parts.

- Fast Cutting. Fiber laser tube cutting is literally hundreds of times faster than traditional cutting methods.

- Angle Cutting. While some tube cutting fiber lasers are 2-axis machines—which are good for cutting pipe to length and other basic operations—many on the market today are 3-axis units, meaning they cut in three dimensions. These tube lasers can cut diagonally through the wall of the tube instead of just straight through at a 90° angle, making them perfect for chamfering.

- Etching. The precise cutting control of a CNC fiber laser allows it to burn a small distance into the surface of a workpiece to etch a design or lettering onto it.

- Wide Range of Materials. A tube cutting laser can process a variety of different metals, and even some non-metallic materials.

- Wide Range of Sizes. The clamping systems of most tube cutting fiber lasers allow them to support pipes and tubes of different diameters, lengths, and even shapes (such as square tubes, angle iron, and other profiles). The nature of fiber laser cutting also permits processing of different wall thicknesses of tubes and pipes.

- Operational Flexibility. With a CNC operation, a changeover to a different size and type of workpiece or cutting pattern can be done in less than a minute in most cases.

- Low Maintenance. The maintenance of a fiber laser is relatively easy and cost effective. Consumables like the nozzle and lens of the cutting head are moderately priced, and unlike blades or other tooling that can wear out quickly, a fiber laser head can keep cutting for thousands of hours with little maintenance.

Filling a Need in the Market

While purchasing a tube cutting fiber laser might not be the right fit for every fab shop, requests for work involving processing metal tubes is on the rise, so it behooves every fabricator to know someone with a tube laser that they can turn to when necessary. If budget allows, however, the fabricator that invests in such a specialized fiber laser could fulfil that very purpose for other shops in their local market.

A short time ago, a salesman was calling on fabrication shops over a range of about 150 linear miles. He noticed that many of them—250 to 300 by his estimate—had some sort of thermal plate processing table in their facility, either a high-definition plasma or a laser. During the same period in the same area, the salesman counted a total of five tube cutting lasers. Being a fabricator by training, the man saw an opportunity and purchased a tube cutting fiber laser from Revolution Machine Tools and started his own company.

A couple of years later, his laser tube cutting services are now in high demand. Approximately half of his time is spent producing parts for customers in the vehicle roll cage industry, while about a quarter is spent making OEM parts for manufacturers. The remaining 25% is filled by doing work farmed out to him from other fabricators in his area who need the services that he can provide. He saw a need in the market and now he’s fulfilling it for himself and other fab shops.

If you perform fabrication work involving metal tubing, consider investing in a fiber laser specifically designed for that purpose. The fiber laser specialists at Revolution Machine Tools would be happy to provide you with more information about the benefits provided by using a fiber laser for tube cutting. Please give them a call today.