With fiber laser machines on the rise, the array of machine tools to choose from for your cutting solutions is growing larger by the day. So what should you choose? As Jeff Bezos would say: “The common question that gets asked in business is, ‘why?” That’s a good question, but an equally valid question is, ‘why not?’.” Great advice from a brilliant man. So in this blog post I’ll help to assist you with your “why” and “why not” questions.

All these questions along with others you may have, play a huge part in which machine to choose.

Thickness… Whatcha Cuttin?

Lets just cut the bullcrap, fiber Lasers are without a doubt #1 at cutting thinner materials. How thick you go before losing your efficiency will depend on the KW’s of the laser. There’s a whole array KW of options, but the most common are between 2-6 KW. A KYSON fiber laser 6KW machine hands down outperforms plasma machines up to 5/16″ thick material. Plasma machines do a pretty good job of cutting a wide range of thicknesses and materials. Therefore if your shop is constantly cutting 3/4″ – 1″ thick material you’ll find the fiber laser may not be for you. With the caveat of cut quality, but I touch on that later.

Take Away: If your cutting steel 5/16″ and under Fiber Lasers are for you!

Order of Slag Please

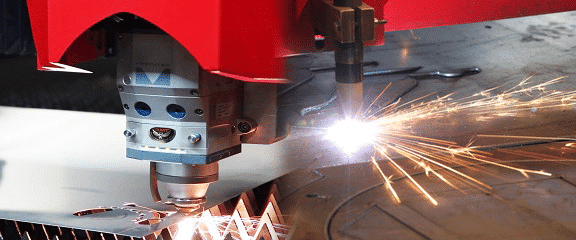

Determining whether or not your cut quality is a factor is extremely vital. The cut quality difference between these two machines is astronomical. Fiber Lasers easily take the cake when it comes to precision cut quality. Today’s fiber optic technology delivers extraordinarily clean precision cuts. Assuming everything is configured correctly, there’s no need to be grinding or tumbling parts at all. Plasma cutting on the other hand usually requires a designated grinder/cleaner to remove the enormous build-up of slag material.

Take Away: Can you handle the slag? No? Plasma Cutting probably isn’t for you.

Loosey Goosey VS Like a Glove

Plasma machines aren’t exactly known for holding excellent tolerances either, but they do get the job done. Most plasma machines will hold tolerances up to a tenth of an inch (0.1). Which is decent, kinda, but fiber laser easily can hold tolerances of a thousandth of an inch (0.001). Plasma cutting also has a much greater kerf (cut line width) than their laser counterpart. You’d be blown away by the cut line fiber lasers can accomplish. For most plate thicknesses the cut is that of a hairline.

Take Away: Laser = Cut Quality Precision

Living on the Edge

Likely one of the last things people consider while buying a metal cutting machine is its overall safety. Don’t be fooled though; it plays a large role in the long-term and short-term use of a machine. Plasma machines cut on an open table, most often using water to gather the fumes and slag. Fiber Lasers come encased and use a high powered dust collector. Which keeps the shop clean and the employee’s safe.

The other real danger with plasma tables is the awkward positions required to perform your job correctly. Such as reaching into the sharp slag covered slats and walking across the same slats to pick up your parts up. Lasers do a much better job at containing the harsh fumes and also providing an easy way of picking up parts off the table. The height and width of the laser tables provide excellent reach and minimal back bending twisting work. Also, minimizing the need to walk across table slats to pick up the out of reach parts.

Take Away: Employees appreciate the cleanliness and safety Fiber Lasers offer

Final Takeaway

Fiber lasers and plasma machines both have their place in today’s shops. The technology implemented in today’s Fiber Lasers is phenomenal compared to their older uncle plasma. All things considered a Fiber Laser brings an excellent value to most shops and provides opportunity to really make your shop production boom! Take a look at the bigger picture and realize there’s a lot to consider before just settling for the cheaper option.