A Press Brake for Every Occasion

As one might expect of the owner of the PressBrake.com website, Revolution Machine Tools knows a little bit about press brakes, and the machines they offer their customers reflect that knowledge. The combined years of experience that their team brings in engineering, selling, operating, and maintaining press brakes has given them the edge over their competition to produce some of the very finest press brakes available in the modern marketplace.

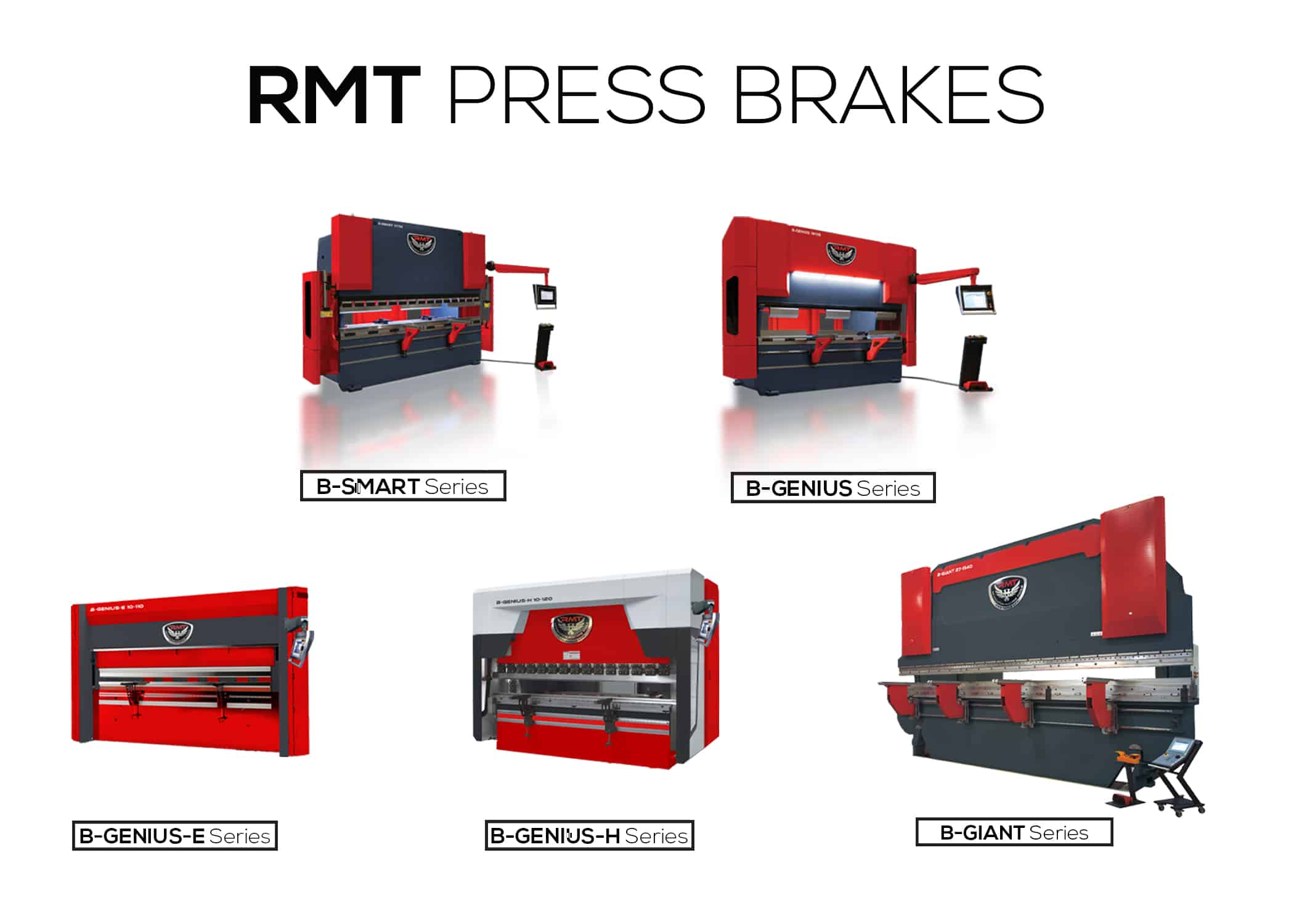

Whatever your specific metal-bending needs, RMT has the perfect solution in the wide variety of models available in their multiple press brake lines.

RMT’s B-SMART Series Press Brakes

“I need to buy a basic press brake,” a fabricator might be heard to say. “Does RMT have anything for a shop that’s just starting out?” Well, there’s no such thing as a “basic” machine in any of Revolution Machine Tools’ lines, especially when it comes to their press brakes—every model is a highly-engineered precision instrument designed with the latest technology so it can accomplish its task flawlessly. However, if a customer was in the market for a “starter” brake, perhaps something with a few less bells and whistles to be affordable to a new business, that press brake would be found in RMT’s B-SMART series.

B-SMART machines come standard with a three axis CNC (Y1, Y2 and X) and are expandable to five axis control. These hydraulicly-powered brakes are available in a variety of capacities, ranging from a compact 6′ by 70-ton model, to a sprawling 20′ at up to 660 tons. B-SMART brakes are designed to have larger daylight, throat depth and stroke to make production easier and more versatile. Two or more machines can be connected and run in tandem, trio or even quad configurations to handle longer parts. There is no need to cut a pit for any standard model B-SMART press brake as they mount flush to the floor.

RMT’s B-GENIUS Series Multi-Axis Press Brakes

“I love the idea of a ‘smart’ press brake,” another metalworker could say, “but I need more control than just three or even five axes. Does RMT carry machines with additional axes controlled by the CNC?” If RMT’s “ordinary” hydraulic press brakes are smart, their IQ increases exponentially when moving up to the multi-axis B-GENIUS series.

Like the B-SMART series, the B-GENIUS brakes are available in 6′ to 20′ lengths with 70 to 660-ton capacities, but these machines come standard with a 7-axis CNC, expandable to 16—or more—axes. The CNC controls the Y1 and Y2 axes for highly accurate ram positioning, along with X, Z1 and Z2 axes, and offers R-axis control through a precision, high-speed servo-driven back gauge. In addition, an automatic CNC motorized wave crowning system gives each brake in the B-GENIUS line even more precise positioning control for improved part quality. The 3D capable graphical control unit simulates the bending sequence and identifies any collision points that exist in the entered program, reducing potential damage to the parts, the tooling, and the press brake itself.

B-GENIUS series brakes are designed to be mounted flush to the shop floor and can be configured in tandem, trio or quad arrangements to accommodate longer projects. They feature large open height, large stroke, and large throat depth.

RMT’s B-GENIUS-E Series Electric Press Brakes

“I’d love to own a B-GENIUS series brake with computer-numeric control over extra axes,” some shop owner might say, “but I’ve decided to go green, both to save the environment and my wallet, so a hydraulic brake isn’t for me.” Naturally, RMT has just the thing for such fabricators with their B-GENIUS-E series of electro-mechanical press brakes.

Standard with a 6-axis CNC (Y1, Y2, X, R, Z1 and Z2), optional additional axes are available, such as X1 and X2, X1 and X2 for light pole production, R1 and R2, X Prime (Delta X) and several others that can give the user the most minute control over the extremely quiet operations of the B-GENIUS-E press brakes.

Available in 5′ to 10′ bending lengths and capacities ranging from 50 to 120-tons, the B-GENIUS-E press brakes consume approximately 69% less energy than their hydraulic equivalents, with 98% energy savings in standby mode. Besides lowering the electric bill, the lack of hydraulic systems in these brakes translates to savings in other areas: no costly hydraulic oil (or having to pay for its disposal); no maintenance costs for repairing hydraulic system components or replacing things like filters and seals; no dealing with work area contamination from leaking oil.

RMT’s B-GENIUS-H Series Hybrid Press Brakes

“Okay, I’d love to save money and the planet with an electric brake,” our hypothetical fourth metal bender may muse someday, “but I really want the power of a hydraulic brake. Can RMT help me out?” Anticipating such a request, Revolution Machine Tools makes available the best of both worlds with their B-GENIUS-H hybrid press brake, offering fast operations using servo motors combined with a highly efficient hydraulic pump.

These 7-axis CNC press brakes (expandable to 14+ axes) are available in 8′ to 14′ bending lengths with 110 to 300-ton capacities and provide extremely precise bending (+/- 0.00003″) even on very small parts with high repeatability. These are the eco-friendly hydraulic brakes, with 65% in energy savings over normal hydraulic machines (while using 95% less oil). The B-Genius-H brakes are also remarkably quiet, operating at a noise level of 63db.

RMT’s B-GIANT Series Big Press Brakes

“Okay, I like the idea that I can run press brakes in tandem to get a longer bend,” our fifth fabricator reflects, “but that doesn’t give me any additional tonnage. I just need a bigger overall brake.” You guessed it—RMT has that area covered as well.

When an ordinary press brake can’t cut it, Revolution Machine Tools has their colossal-sized B-GIANT series machines ready to fill the bill. These behemoths are available with up to a 40′ bending length and up to an astonishing 20,000-ton capacity! In addition, custom machines are also available to be built to order. The machines are designed to be run in tandem, trio and quad configurations, if needed, for even longer bending lengths. The standard 7-axis CNC is expandable to 14+ axes.

The Sky’s the Limit for Bending Possibilities

From a tiny fab shop operating out of a hobbyist’s garage, to a huge multinational manufacturing conglomerate with factories across several continents, Revolution Machine Tools produces press brakes for every imaginable requirement—and the ability to custom build brakes for any yet-to-be-imagined circumstance.

When you need a new press brake, always be sure to call the experts at Revolution Machine Tools to find the perfect machine for your precise bending needs.