The More Expensive the Toy

You were excited as a kid to get the toy that everyone in your class wanted. It had flashing lights, made noise, and was the coolest thing you had ever seen. It was also a lot more expensive than anything else you had ever received from your parents as a gift. You begged for months, promising better performance in your chores, better treatment of your siblings, agreeing to never complain about the food on your plate, vowing to always get your homework finished early, all to pave the way to receiving the desired present.

When the long-awaited day finally arrived, you opened your perfect gift and couldn’t complain—everything looked like it was supposed to. You tried it out, running it through all the operations listed on the box, and it exceeded your expectations. As you tested its limits, your parents gave you a gentle caution, “Please be careful with it. It cost quite a bit, so you don’t want to ruin it.”

You nodded, but inwardly laughed off their concerns. After all, this was supposed to be the toughest toy of its kind on the market. In the ads they showed it doing all sorts of things that would easily break other playthings of the same type. As you pushed the boundaries of its capabilities, something your grandmother once told you came into your mind: “Remember that the more expensive the toy is, the easier it breaks.”

You again scoffed to yourself, bound and determined to completely enjoy your new acquisition until it finally wouldn’t work any longer. That eventually did happen—sadly just three days after you first received it. Through your tears your parents explained that because of how complicated your new toy was, there were many things on it that could break, and the damage that you had done to it simply wasn’t fixable.

You looked over at your baby brother playing with your old construction blocks that had been passed down to him and thought back fondly on all the many happy hours you had spent with those much simpler objects. You realized that grandma was right and vowed then and there to always take good care of your possessions, never using them in ways they weren’t intended.

Best Practices of Press Brake Operation

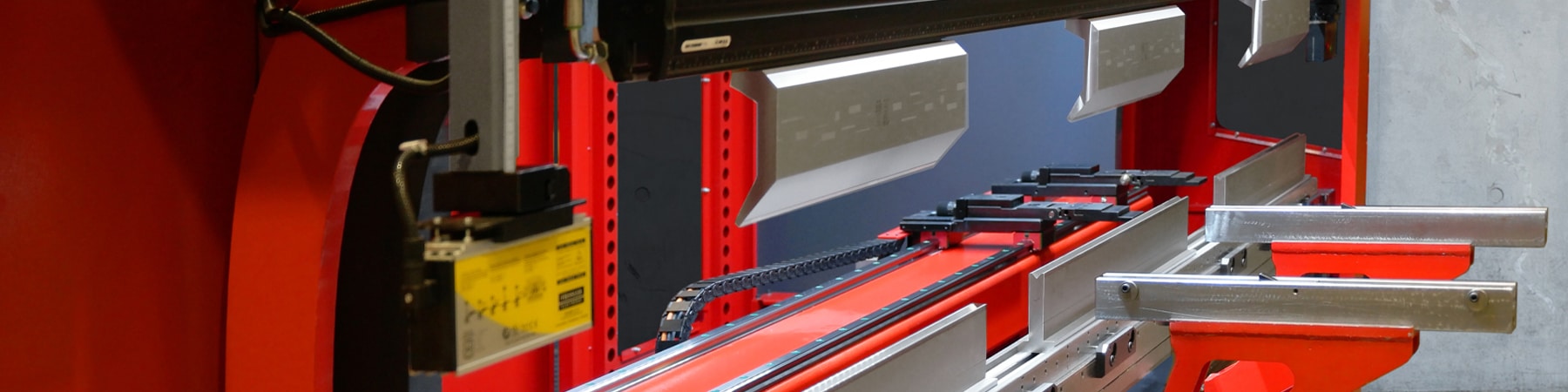

The hydraulic Y1/Y2 CNC press brake sitting on your shop floor may well be the most expensive toy you’ve ever owned. Much like your treasured plaything of yesteryear, it too has outlined procedures for proper use and limits that cannot be safely exceeded.

The following are a few of the commonsense guidelines that unfortunately are far too often ignored by press brake owners and operators alike:

- Respect the Rated Tonnage. Unlike the old mechanical press brakes that could often generate loads exceeding their rated capacities, today’s hydraulic machines should be operated well within their advertised specs. Too much tonnage applied too often can damage a press brake. If you need to bend 10 feet at 100-tons most of the time, don’t purchase a 10′ x 100-ton press brake, go a couple sizes larger. The maximum capacity of a press brake is simply what it can be operated at on rare occasions, not what it should be pushed to daily.

- Determine the Required Bending Load. Operators should understand the load needed to make each bend, based on factors such as the type of tooling required, the length of the bend, and the properties of the metal itself, including thickness. This will allow an operator to properly distribute the load on the bed to avoid damage to the machine or tooling. Full tonnage should never be applied to a job that doesn’t cover at least 60% of the distance between the housings. Attempting to do so with a smaller workpiece might permanently deflect the ram and the bed and may even damage the hydraulic cylinders.

- Inspect the Tooling. Using damaged punches or dies could result in ruined workpieces, broken tooling, harm to the operator and bystanders, or even damage to the press brake itself. Improper tooling can wind up being embedded into the ram or bed or cause an issue such as a ram upset (when the ram is permanently deflected). Always inspect punches and dies for cracks or dents before use and clean them regularly, applying oil to deter rusting. Be sure to understand the load limits of your tooling by consulting the manufacturer or supplier.

- Complete a Pre-Job Check. Performing a quick but methodical inspection of critical aspects of a press brake prior to each job is essential for safeguarding a smooth operation. A checklist should be established by the shop manager that can be followed to ensure thoroughness, from double-checking the specs of the job and confirming machine parameters to seeing that the tooling is seated correctly.

- Prevent Part Collisions. Every press brake operator knows the perils of part collision, the dilemma of a flange being bent that is too long for the allotted space, causing it to impact on the punch, clamps, ram, bed, or even the back gauge. This is especially common when bending a deep U-shaped part like a box. Various precautions can be taken depending on the job, such as using taller tools, a punch extender, a die riser, low-profile die holders, or temporarily removing a manual crowning system. If your CNC control unit allows the bend to be simulated before the job is run, the operator should always take that step to reveal any potential collisions or other problems.

- Follow All Scheduled Maintenance. It’s called preventative maintenance for the simple fact that it can usually prevent issues that would require emergency maintenance when your workflow can least afford it. Operators and shop technicians alike should be aware of the maintenance schedule and be capable of properly performing those tasks when they are needed. The level, quality, and temperature of the oil in a hydraulic press brake should be checked regularly. Other essential maintenance tasks include lubricating moving parts, cleaning surfaces, and replacing filters. An extra copy of the press brake manual should be created and stored away from the work area in case the original is lost or damaged.

Press brake operators should also watch—and listen—for anything during a bending job that doesn’t seem right. Any suspected problem, no matter how small, should be investigated to see if there is a difficulty that requires a resolution. As simple as their functions may seem at times, press brakes are very complicated machines that can have a variety of challenging issues arise that effect their performance or longevity.

You’ve invested quite a bit of money in your press brake. Be sure that you and your staff invest the time, care, and common sense required to keep it running smoothly for many years to come.