The Bigger They Are, the More They Need Maintenance

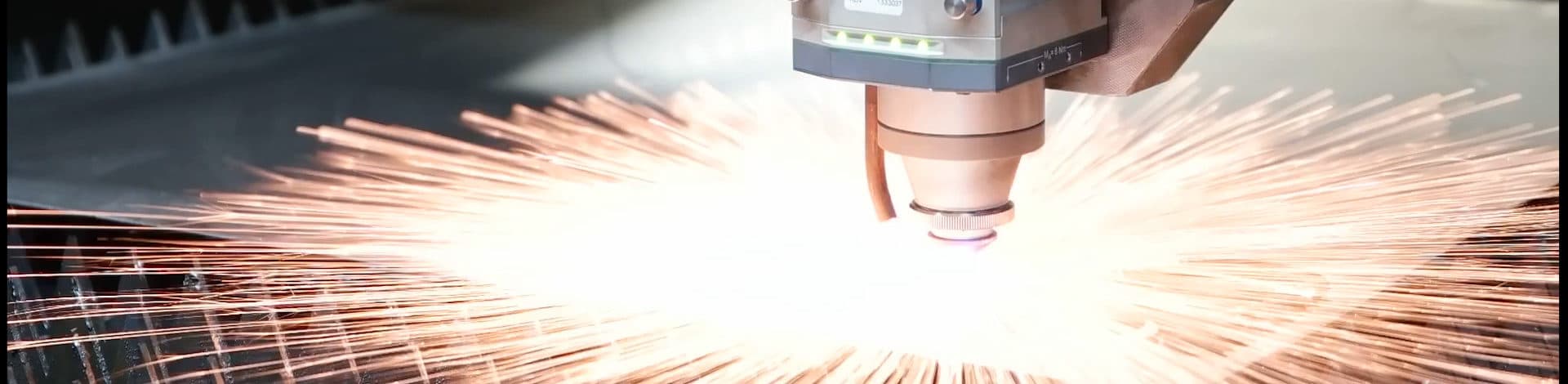

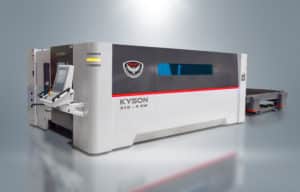

Your fiber laser may well be the most complex—not to mention the most expensive—piece of equipment in your fab shop, but it could also be the most neglected as far as regular preventative maintenance goes. At least that could be the case when compared with the upkeep your staff puts into machines that have more direct physical contact with their workpieces, such as press brakes, plate rolls and shears.

“What’s to maintain?” you might ask. “After all, a beam of light cuts the metal and out rolls a finished part, easy-peasy. Just keep the moving parts greased and everything takes care of itself, right?”

Wrong. The old boxing idiom, popularized by 5’1″ Barbados Joe Walcott around 1900, states, “The bigger they are, the harder they fall.” This saying can also find application in the world of fabrication equipment too—the more complex a machine is, the larger and costlier the problems you’ll likely have on your hands should it go down.

Keeping the moving parts greased is the first step of proper laser maintenance of course. You should grease all grease points on the machine according to the manufacturer’s recommended schedule. Some locations that require panels to be removed in order to grease them should be approached carefully, or possibly postponed until your next visit by a factory-trained technician. You should also check the on-board greasing unit of your fiber laser to make sure it has grease in it.

Earth, Air, Fire and Water

The saying, “cleanliness is next to Godliness,” applies more to your fiber (or other) laser cutter than virtually any other machine in your shop, but if yours is a typical fab shop, then the reality might be that “cleanliness is next to impossible.” Still, with as large of an investment as you made in your laser, you will want to keep it in an area of the shop that’s as dirt-free as possible, if not in a separate room or enclosure. You will also want to clean its components on a frequent basis, daily in some cases.

Daily, weekly and monthly cleaning of your fiber laser will take a little time away from its operation, but your productivity will increase in the long run as your machine continues to operate at its peak performance level, having fewer hiccups and downtime along the way. While the following contains suggested schedules for cleaning and inspecting the different systems, you should always follow the recommended schedules from your fiber laser manufacturer.

A colorful way for an operator to keep a mental checklist of all the areas that need routine cleaning and inspection on a fiber laser might be to classify them according to the classical elements. The term “classical elements” doesn’t refer to the more than a hundred chemical elements denoted by today’s knowledge of atomic structure, however, but rather the elements as understood by many diverse ancient civilizations—earth, air, fire and water.

- Earth in the classical sense can refer to not only soil and rock, but also metal. In our checklist’s case, it refers to the scrap, slugs and slag left behind after the cutting operation.

- At least daily—and preferably after each job—clean out the bins, drawers or conveyor trays that collect all the scrap and slag that drop during each operation. Never allow the slag drawers to overload or they can interfere with the operation of the laser.

- Regularly clean the buildup of slag on the slats in the work and exchange tables. Any dross on the upper edges of the slats should be cleaned immediately after each job to ensure that the next operation will take place on a flat surface for greater accuracy. Specialized grinding tools exist in the market that can assist with this.

- Inspect and measure the height of the slats regularly to make sure they haven’t worn down below acceptable levels through use or cleaning.

- Clean the dust collectors and any other areas where dust builds up to avoid accidentally forming thermite, a mixture of aluminum and an oxide of another metal like mild steel. If ignited, the thermite dust will burn at a high temperature, causing significant damage to the equipment and endangering the shop and its personnel.

- Regularly clean the components of the drive system to remove any laser cutting byproducts or dust that could interfere with the movement of the cutting head through its different axes.

- Air would include not only the normal air flow within the machine, but also the assist gases that help the laser make cleaner cuts, such as oxygen, nitrogen and shop air.

- Fans used as part of the cooling system in laser cutting need to be kept free of debris, as do their filters, which should be checked and cleaned weekly.

- It is essential to also regularly clean the air filters in the electrical cabinet to keep it from overheating.

- If compressed air is used as the assist gas, a monthly check is recommended to make sure the lines are free of moisture and contaminants and that air filtration is working correctly. Proper air pressure should also be checked, and it is highly recommended that a dedicated compressor is used for the laser, so pressure won’t be decreased by other simultaneous operations in the shop.

- If other assist gases are used, they should also be checked regularly to make sure they are dry and free of contaminants. In addition, leaks should be checked for every time a gas bottle is changed, as well as when the operator notes a significant change in the gas usage or power output. The simple way is to apply soapy water to the bottles, connections and hoses, which will reveal leaks by creating bubbles at the leak site. Besides being costly and affecting the cut, assist gas leaks can also pose health risks if not caught.

- Fire refers here to the torch or cutting head of the laser, as well as all systems related to the optics.

- Daily clean the lens, height sensors and other optics of your fiber laser using a microfiber or lint-free cloth. While a fiber laser has fewer optics than the extensive system of a CO2 laser, they still need to be kept free of dust and other contaminants that can interfere with the precision of the cut or even damage a lens.

- Any time maintenance is performed on the optics, including daily cleaning, make sure they are properly aligned to factory specifications for optimal performance.

- It’s generally a good idea to replace any optics with OEM parts designed for your specific machine rather than take a chance with aftermarket lenses.

- Water refers to actual water used in the cooling system, as well as other chemicals and the chiller itself.

- Check the water level of the cooling system daily before starting the laser.

- Check the conductivity of the water at the beginning of the workweek. The water in the chiller can gradually increase its capacity to conduct electricity, which can lead to critical failures in the system. Resin and other additives can be used to deionize the water and reduce its conductivity. Running the chiller for a few minutes before cutting can also reduce the level of conductivity.

- Clean the chiller weekly, along with all components of the cooling system, such as condenser coils. (This should also include the air filters and fans, as mentioned above).

- Any other refrigerants or chemicals used in the system should be changed or replenished at regular intervals and kept free of contaminants.

- The operator should keep a close eye on the chiller’s temperature gauge to ensure that it stays within range while operating. Otherwise, serious damage to the resonator can occur.

Besides cleaning the fiber laser components, the area around the machine should be tidied up at the end of the workday to eliminate any debris, dirt or loose wires that could pose a hazard to either the shop workers or the equipment.

Call the Experts

As one of your most expensive assets, your fiber laser would benefit from having a preventative maintenance agreement in place with a qualified laser service center. Even though it will involve some expense and downtime, the alternative is that your fiber laser will likely go down at a time not of your choosing and will almost certainly incur a far steeper cost to repair when that time comes.

Along with a comprehensive inspection of the fiber laser, some of the procedures performed by technicians during a preventative maintenance visit can include:

- Checking the water level.

- Performing a water treatment flush to remove any bacteria if the water hasn’t been replaced recently.

- Checking the ball screw for backlash in the Z-axis.

- Testing for backlash in the other axes.

- Checking the linear rack and pinions for all of the axes.

- Verifying that all of the motor couplings are in good shape.

- Performing a thorough wipe down of the inside of the machine to make sure there is no debris obstructing any movement or process.

- Removing covers and greasing those areas that don’t require frequent lubrication.

Preventative Maintenance Produces Peak Performance

To maintain the optimal cutting performance of your fiber laser, regular maintenance is a must, just like your annual physical, your six-month dental exam or your vehicle’s routine oil change.

The combination of a preventative maintenance visit by a technician two to four times a year along with daily upkeep by dedicated members of your staff should allow you to enjoy the benefits of your fiber laser well beyond its expected lifespan.