Plasma and Lasers—Aren’t They Basically the Same?

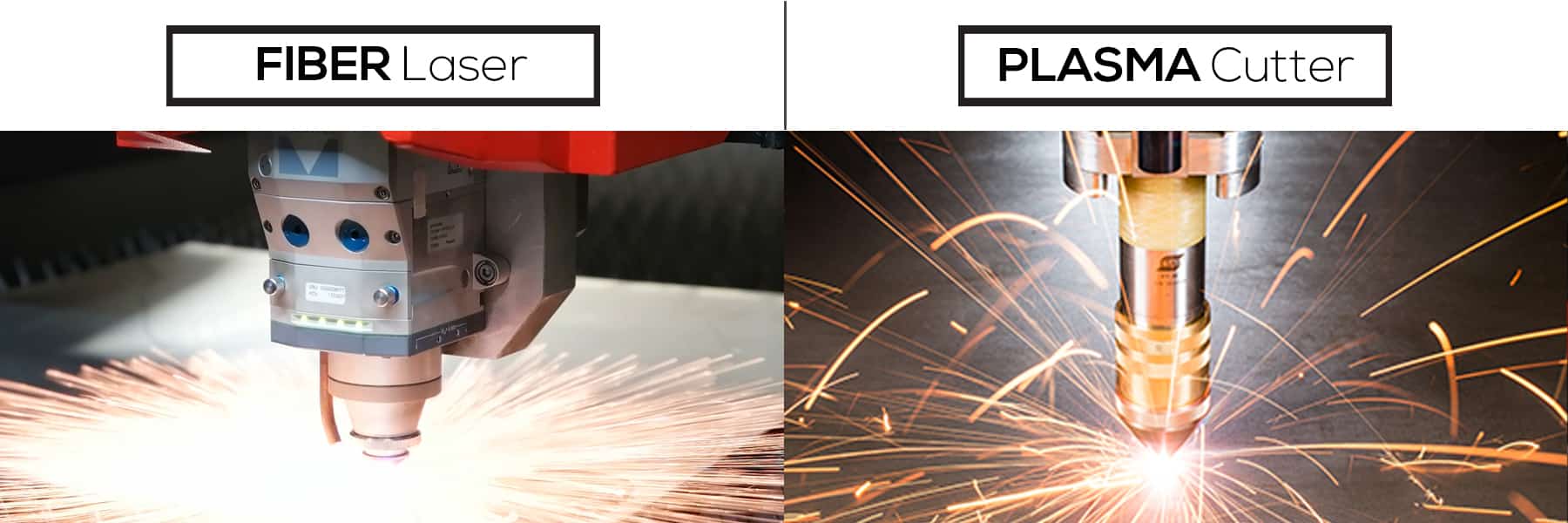

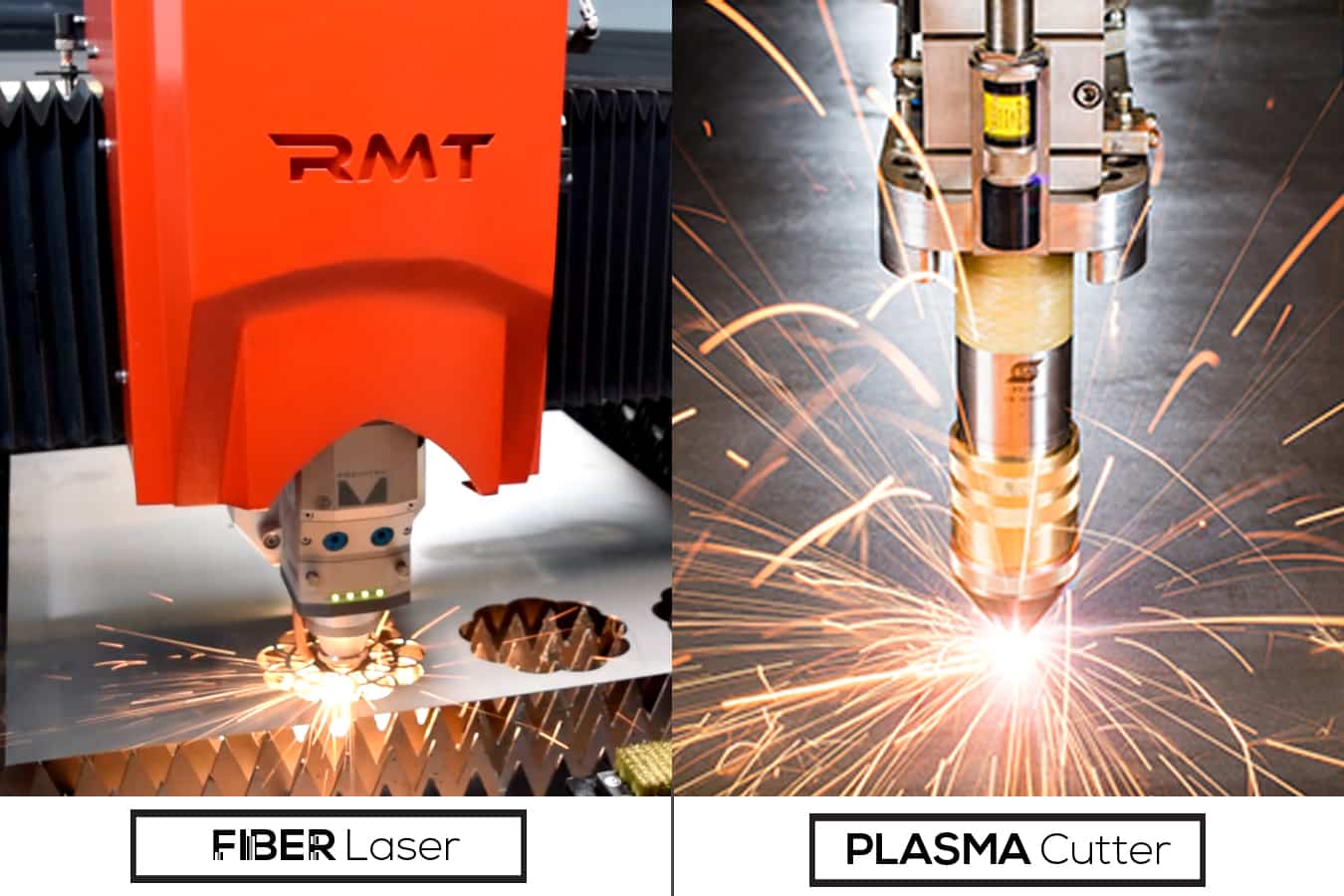

Both plasma cutters and fiber lasers cut metal with heat, and they usually involve a cutting head that moves on an assembly above a table holding a large workpiece, but that’s about as far as the similarities go.

A plasma cutter uses a combination of inert gases and compressed air that is forced at high speed through a very constricted opening in a nozzle. The power supply is wired to an electrode in the nozzle and to the workpiece, allowing an electric arc to pass through the gas between them, ionizing it and transforming it into the fourth state of matter known as plasma, which is distinct from the other three (solid, liquid, and gas). The superheated plasma can cut through conductive metals that have a low melting temperature, such as mild steel, stainless steel, and aluminum. Plasma cutters work extremely well in cutting thick metal.

A fiber laser uses solid state diodes to generate light that is introduced into a spool of optical fiber implanted with rare earth elements. The light causes the atoms of these elements to release photons that are in phase with the photons in the light, amplifying it. The light continues to amplify as it bounces back and forth through the fiber before being released as a high-power beam that is focused onto the surface of a workpiece to cut it. Fiber lasers are ideal for cutting thin metal.

Comparing Fiber Laser and Plasma

Which is better, a plasma cutter or a fiber laser? That’s sort of like asking whether a shovel is better than a teaspoon. While they can perform some of the same jobs, each is better suited to certain tasks. Here is a comparison between the two in several different areas:

- Accuracy. Fiber lasers are at least twice as accurate as plasma cutters, with a positioning accuracy of up to 0.05mm and a repositioning accuracy up to 0.02mm.

- Detail Work. Fiber lasers are better for intricate work and cutting out small parts.

- Controls. Both fiber lasers and plasma cutting machines can be equipped with a CNC (Computer Numerical Control) for greater control, accuracy, repeatability, and production speed.

- Cut Edge Quality. Fiber lasers yield a very square, quality cut with limited surface roughness and very little deformation. Plasma cutting produces a wider kerf than laser cutting, creating more pierce splatter, and it always leaves some bevel to the cut edge.

- Cut Part Precision. Because of their wider kerf, plasma cutters have limitations on how small a cut they can make on an inside part contour. Fiber lasers are better able to deliver a finished part that is comparable to the dimensions of the programmed part, also leading to greater repeatability.

- Cutting Speed. Fiber lasers can produce very fast cutting speeds, some easily managing 400 inches per minute on thin sheet metal. Plasma cutters can reach higher speeds than lasers on medium and thick plates.

- Engraving. Fiber lasers can engrave metal without cutting all the way through a workpiece, something plasma cutters can’t.

- Heat Affected Zone. Fiber lasers produce a much smaller heat affected zone (HAZ) than plasma cutters. The HAZ on a workpiece is a non-melted area that has had its structural properties change due to exposure to the high temperatures of the cutting process. These changes weaken the area, making it more liable to distort, experience fatigue, or develop cracks in its surface.

- Material Type. Fiber lasers can cut a wide variety of metals, not to mention other materials like plastic, wood, ceramics, and glass. While plasma cutters can only cut materials that conduct electricity, they are very effective in cutting metals with reflective surfaces, something that is dangerous to try with a CO2 laser because of the wavelength of its beam. Fiber lasers, with their much narrower beam, can usually cut reflective metals, but the process generally must be slowed down, using less power, to allow the beam to overcome the reflectiveness of the material in the piercing stage. Once the beam has penetrated the material, it can interact with the more absorptive molten metal and make an efficient cut.

- Material Thickness. Fiber lasers are better for cutting thinner sheets of metal, as they don’t affect the surrounding material as much as plasma cutters do. Plasma cutting is generally superior for thicker plates of metal.

- Operating Cost. Plasma cutters have more consumables that are used up at a faster rate than those of fiber lasers, and often require time consuming secondary operations usually unneeded with lasers to remove slag and otherwise finish workpieces. Added up, plasma machines can sometimes be three to four times more expensive to operate than fiber lasers.

- Purchase Cost. Fiber lasers, while coming down in price in recent years, are a much more expensive initial investment than most plasma cutters.

- Safety. Both fiber lasers and plasma cutters can produce dangerous radiation and harmful dust and gas. It is important that all recommended safety precautions are used with either cutting method.

What Cutting Machine Is Right for Your Shop?

Your circumstances can be very different from those of your closest competitor, so you must carefully weigh all the pros and cons of both methods of high-tech cutting to determine which is the best one for your ongoing projects.

Do you need to start off with as low of an investment as possible? Do you mostly cut thick metal? Do you mostly cut highly reflective metal? Can you get by without the greatest precision for your upcoming jobs? Depending on how you answer these questions, plasma cutting may be the best method for you right now.

Are you willing to pay more now for a greater return on your investment later? Do you mostly cut thin metal? Do you need to cut materials other than metal? Do you need to perform very intricate cutting? Depending on your answers, a fiber laser might be the best way to proceed. While more shops these days are migrating to fiber lasers because of their accuracy and versatility, that doesn’t necessarily make them better for your applications than plasma cutters. A wise approach to determining which technology is the best fit for you is to talk to a distributor that carries both machines, if possible, or at least fiber lasers. Your local laser dealer can let you know if a fiber laser will fit your budget as well as which machine matches all the variables of your standard and potential jobs. If you have a trusted advisor who is willing to take the time to consult with you without trying to pressure you into a sale, you should be able to get a very good idea of your ideal path to future productivity.