The Impact of the Laser

Lasers have contributed to the improvement of modern life in many ways. Lasers can measure distances and be used to gauge environmental issues like cloud coverage or airborne pollutants. The precision of a laser beam makes it an effective surgical tool, and lasers are used in everyday items, from laser pointers to DVD players.

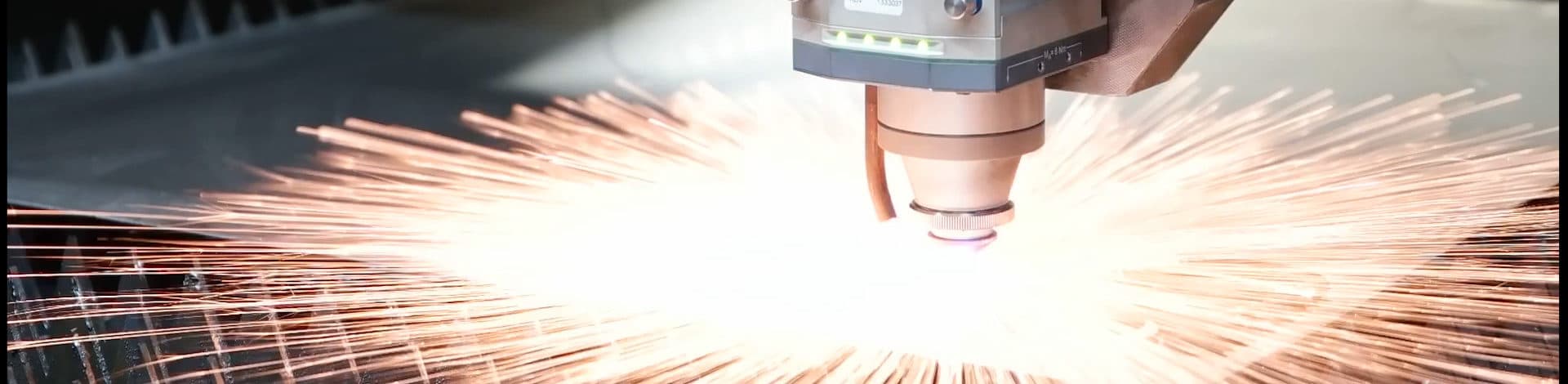

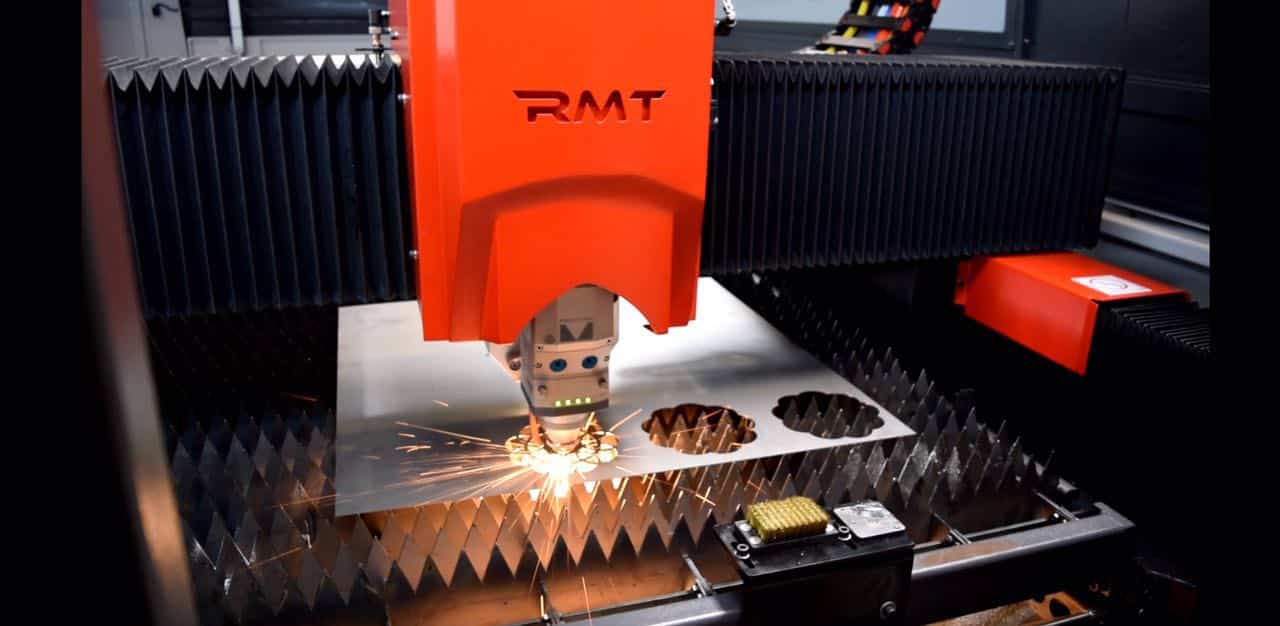

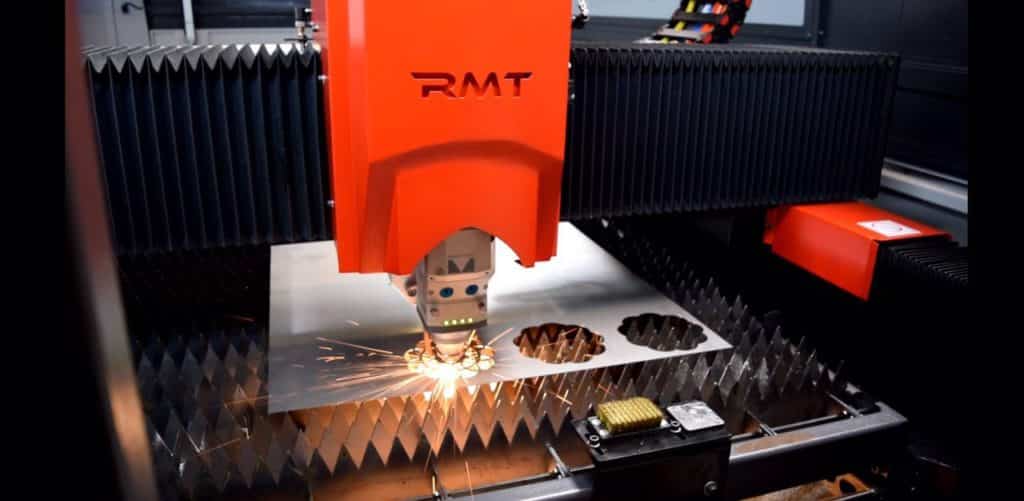

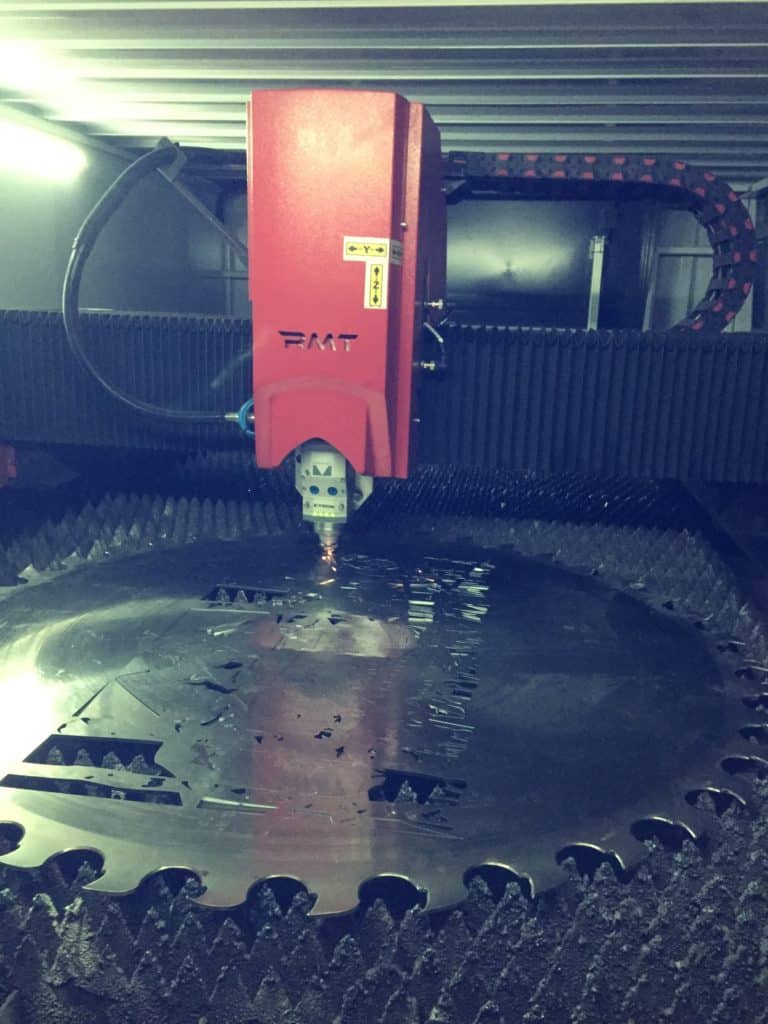

In the metalworking field, lasers have found a variety of uses, like noting exact dimensions or deployment in light curtains to help safeguard press brake operators, but by far the most common application of the laser in a shop is in high-powered metal fiber laser cutting. The advent of the fiber cutting laser forever changed the look and operation of large production metal fabrication facilities and has had a lasting impact on many smaller shops as well.

Advantages of the Laser-Equipped Shop

Not every metal fab shop needs a laser—some small operations with limited functions are just fine without one. The shop that wants to grow and be viable in an ever-growing competitive marketplace, however, soon learns that laser cutters can give them the advantage they need.

While not an inexpensive machine, a laser offers an impressive ROI—return on investment—that will easily justify its purchase and upkeep by the increased flow of business it can potentially bring to almost any forward-thinking metal fabrication operation.

Since their introduction, carbon dioxide, fiber, and other lasers have given fab shops many advantages over the traditional metal cutting machines on their floors:

- Lasers have a small cutting area, with the beam focused to a diameter much smaller than the hole of any drill or the cut width of any saw. This allows for extremely fine detail work unavailable with traditional metalworking machines.

- Lasers can have an accuracy of +/-0.1 mm, offering high precision parts that don’t need an after-treatment, like thermal cutting requires.

- Lasers can have a repeatability of +/- 0.05 mm, guaranteeing nearly identical parts each time.

- Lasers leave only a small burr that may not even need to be removed.

- Lasers can cut a wide variety of metals, as well as a wide range of non-metallic materials.

- Laser cutting is much faster than mechanical or other heat-based cutting methods, especially when complex cutting is needed.

- Laser cutting is more energy efficient than plasma cutting for medium to thin sheet metal.

- Lasers create a very small heat-affected zone, meaning less deformation to the workpiece than some other cutting methods.

- Laser cutting doesn’t apply high physical forces to a workpiece that could potentially deform it, unlike shears, waterjets, and other cutting methods.

- Lasers have less waste and mess than some methods, such as waterjet cutting.

- Lasers have less noise pollution than most other cutting methods.

- Lasers don’t require a change of tooling for different cuts.

- Lasers have no tool wear due to their contactless cutting.

- Lasers are scalable, with the same machine possibly being able to micro cut surgical implements as well as shape structural steel.

- Lasers can easily be set up for automation. Many machines run on a dual interchangeable platform, allowing operators to load and unload one platform while the workpiece on the other platform is being cut.

- Tube lasers can cut a wide variety of profiles, from tubes to angle iron to open channels.

- Laser cutting machines can also be utilized for laser marking.

Advantages of Fiber Lasers over CO2 Lasers

While all laser cutters benefitted the shops that upgraded to them, when fiber lasers became available, those that changed over to them found they delivered some distinct advantages over CO2 and other traditional lasers:

- Fiber lasers can be built to have more power than CO2 lasers. Their solid-state resonators can generate almost limitless power.

- Fiber lasers offer faster cut speeds than CO2 lasers. They have a higher beam quality so they can cut through thicker metal more quickly.

- Fiber lasers can cut reflective material like aluminum, copper, and brass, something that is dangerous to do with a traditional laser.

- Fiber laser beams leave a narrower kerf and less distortion due to expansion of the workpiece, allowing for tighter nesting and better material utilization.

- Fiber lasers have lower operating costs than other lasers, with a 20–50% savings over CO2.

- Fiber lasers offer lower maintenance expenditures in both time and money. They have fewer moving parts than CO2 lasers and require only minimal maintenance and rare part replacement.

- Since fiber lasers don’t have mirrors like CO2 lasers, the need for repeated adjustment and alignment is eliminated.

- Fiber lasers are easier for operators to learn, lacking the complex adjustments needed with CO2 lasers.

- Larger table sizes can be accommodated with fiber lasers due to the lack of mirrors—they just need a longer delivery fiber.

- More compact table sizes are possible with fiber lasers since fiber optics can be bent or coiled.

- Some fiber laser cutting machines feature combined plate and tube cutting capabilities, an option not practical with CO2 laser systems.

The Cutting-Edge Shop

Each new metalworking technology that has been introduced has given craftsmen a distinct advantage over their predecessors. A giant step was taken in the 1980s with the dawn of CO2 lasers and the benefits they brought, but that was nothing compared to the leap forward in the industry that came with fiber laser cutting technology and its ground-breaking developments.

The age of the fiber laser hasn’t been a stagnant one, either, with additional advancements being continually announced in the field. While it took CO2 lasers two decades to reach a 4-kW cutting power level, that was something fiber lasers reached within five years of their introduction. The 10-kW boundary was crossed less than five years after that—a range CO2 lasers can’t match—and now 100-kW and larger fiber lasers are available for use in heavy industry.

Most fab shops, however, get by easily with a laser that’s far less than 10-kW, giving them just the right speed, accuracy, and power for almost any fabrication job they encounter. With dropping prices and the availability of smaller machines, most fab shops in the next generation will likely sport fiber laser cutting of some sort.