Make Ready for Your Machine

The purchase has been finalized; the ink has dried on the agreement; the down payment has been made. You are now committed to take possession of your brand-new metalworking machine (or newly acquired piece of used equipment). Being past the point of turning back without incurring a costly restocking fee, there is only one option available to you moving forward: get your shop prepared and ready for the new machine!

Buying your equipment was the easy part. Getting the machine delivered, installed, running, and bringing in income for your shop is what takes some effort. Even if you’ve cleared a spot for it, your new machine tool or piece of metal fabrication equipment won’t be ready to go “out of the box,” like your last stereo or toaster oven. Serious preparations must be made in your shop, or you will be in for some considerable headaches once the machine arrives.

Preparing Before Purchasing

The sad truth is, if you don’t start preparing long before you make your purchase, you may have to wait a while to operate the machine—or even to install it. (And in rare cases, you may be prevented from installing that machine at your location at all.)

The fundamental question to ask before you start shopping for your latest toy is simply, “Can my shop sustain this machine?” Every possible consideration needs to be studied:

- Is the machine too big to fit through my shop door?

- Is the machine too large or heavy to be rigged and moved within my facility?

- Will the foundation of my shop support the machine’s weight and vibrations?

- Can the correct voltage be run to power my machine and its accessories?

- Are there any environmental issues to consider, such as being able to vent the machine?

- Are there any zoning ordinances to look at, such as noise restrictions?

Be sure to learn if there are any potential roadblocks to receiving, installing, and operating the equipment at your location before you buy. Resolve the problems if you can do so; postpone the purchase if you can’t.

Consulting the Crew

You’re the boss. You want a specific machine, you are pretty sure you can justify your need for that machine, and you’ve worked out all the financial details to make sure it fits within your budget. However, an essential question to ask yourself is, “How well did I consult with my team on planning this purchase?” It doesn’t matter how skilled a fabricator you are, or how loyal to you your employees may be, if you don’t consult with the people who will be working near or operating the equipment on a day-to-day basis, you are guaranteed to overlook some critical issues. Even if your entire staff agrees that your shop needs to acquire the Acme Wingnut Bender 3000, you should confer with them on several significant concerns, including:

- Shop space. You think to yourself, “We’ll just move the old shear to the corner to make room for the new machine.” Asking your team their thoughts may shine some light on likely difficulties such a move might make for other processes in the shop.

- Workflow. You’ve got the perfect spot picked out for your new machine. It’s nice and central and you’ve figured on having plenty of space around it to support employee movement. Did you calculate for all aspects of workflow, though? How convenient will it be to load blanks into the machine? How about unloading parts? Is there easy access to finishing equipment? Is there enough room for all support machinery? Asking your operators and other workers for their input may help you further increase the productivity you expect to get from your new purchase.

- Training. How many of your employees are trained for this type of equipment? How many are willing to cross train on the machine? How dedicated are your people to reading the manual and avoiding shortcuts? Some frank discussions may give you a good idea on how quickly you will have trained operators on board and ready to go.

Implementing the Installation

Once you know that your shop can support the equipment you are buying, you should begin lining up all the necessary preparations to assure a largely worry-free install. Key things to look at include:

- Foundation. Just because your shop’s foundation will take the weight and movement of incoming equipment, there other aspects of it to look at. Is the floor perfectly level? If not, that will have to be accounted for when the machine is leveled and aligned. Will your new machine require a pit? The time to order up the concrete cutting is not while it’s sitting on the flatbed, ready to come in the door. Will the equipment require any additional reinforcements, such as the installation of anchor bolts? Knowing how your machine will interact with your shop’s floor and foundation is a necessary step for having a successful install.

- Utilities. Unless your new machine is a hand-crank slip roll, you almost certainly will need power. Have a professional electrician ensure that your shop has the proper capabilities to support the load that will be drawn by the new machine, including all support equipment. The location of existing and new lines to your shop may be a factor in deciding where your machine needs to be positioned. Are there any other utilities, supply lines, or waste removal considerations that need to be looked at ahead of time? Certifying that everything that needs to be hooked up to your new machine is already in place will make for a much smoother install.

- Environment. Have you planned for sufficient lighting, ventilation, temperature control, and other factors of the immediate environment where the new machine will be located? Everything from workflow to the shop’s traffic flow should be deliberated prior to installation.

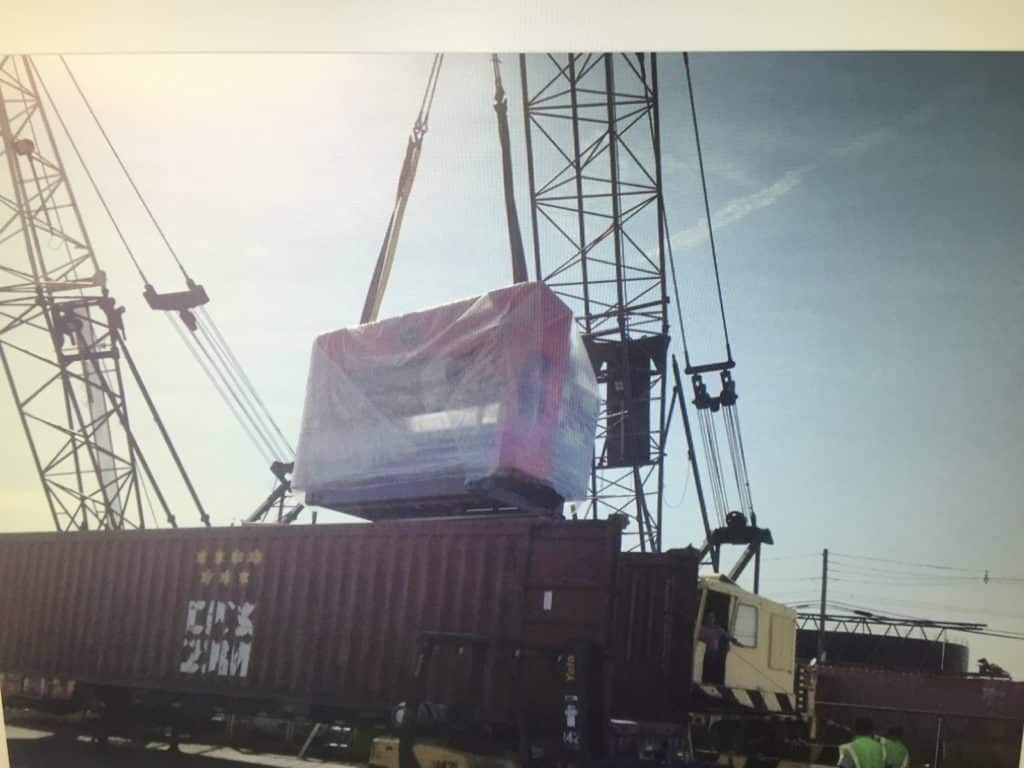

- Logistics. Triple-check every detail of the shipping and rigging of your new equipment. Having a crane vehicle standing by for half a day while waiting for a truck can be costly, so coordinate all aspects of the delivery, unloading, and moving of your machinery to make it as seamless as possible. Are you trading in or selling off an old machine to make way for the new one? If so, you may want to synchronize the departure of the old with the arrival of the new so that the same rigging equipment can be used for both. Keep your shop’s schedule wide-open during the planned delivery and installation times to avoid potential conflicts of space or personnel during the transition.

A Steady State of Preparation

Keeping your shop prepared for new equipment should be an ongoing endeavor. Rushing at the last minute every time a new acquisition is about to come through the door will lead to frustration and potential downtime. There are some things you and your team can do on a regular basis that will keep every future machinery purchase a relatively easy transition:

- Have regular inspections of your shop, both by your own personnel and by trained professionals.

- Keep a clean and organized shop and regularly analyze the workflows for all processes and tasks.

- Constantly monitor your shop for safety issues. Don’t wait for an OSHA inspection to discover potential hazards.

- Certify your staff. Arrange for factory training and other machinery-specific education for your employees. Encourage their attendance in vocational classes to expand their skill sets

With the right preparation, every machine install can be a time of company-wide celebration instead of a dreaded nightmare. Careful planning will pay off with a successful installation time and again.