Some Well-Rounded Metalworking

While most metal fabrication operations today likely involve flat sheets or plates of metal being cut or bent, there is still quite a bit of work done on more three-dimensional pieces and profiles like angle iron, tubes, and pipes. Even the ancient world saw a significant amount of metal pipe being connected for the transportation of water, with lead pipes used two millennia ago in the Roman Empire and copper pipes appearing over two millennia before that in ancient Egypt.

In the modern world, Revolution Machine Tools offers one of the widest selections of metal fabrication machines on the market, so it shouldn’t be surprising that they carry a diverse selection of metalworking machines directly related to the tube and pipe industry.

RMT’s Tools of the Pipe Trade

The crowning gems in RMT’s lineup of pipe-working machines are their RMT Pipe Spool Master™ Series that can perform such functions as beveling, threading, and facing pipe, and do so while the pipe is held completely stationary. These revolutionary machines clamp a pipe of any length securely while the easily interchangeable tooling spins around the pipe end to perform its required function. These ‘reverse lathes’ are available in 11 models:

- RMT PSM-8 Pipe Spool Master™ manual beveling machine for 1″ to 8″ OD, 5″ Z-axis stroke.

- RMT PSM-16 Pipe Spool Master™ manual beveling machine for 3″ to 16″ OD, 6″ Z-axis stroke.

- RMT PSM-32 Pipe Spool Master™ CNC beveling, boring, and facing machine for 6″ to 32″ OD, 7″ Z-axis stroke (optional upgrade to up to 24″).

- RMT PSM-40 Pipe Spool Master™ CNC beveling, boring, and facing machine (optional upgrade to allow threading) for 12″ to 40″ OD, 7″ Z-axis stroke (optional upgrade to up to 24″).

- RMT PSM-48 Pipe Spool Master™ CNC beveling, boring, and facing machine (optional upgrade to allow threading) for 12″ to 48″ OD, 7″ Z-axis stroke (optional upgrade to up to 24″).

- RMT PSM-60 Pipe Spool Master™ CNC beveling, boring, and facing machine (optional upgrade to allow threading) for 16″ to 60″ OD, 7.87″ Z-axis stroke (optional upgrade to up to 24″).

- RMT PSM-80 Pipe Spool Master™ CNC beveling, boring, and facing machine (optional upgrade to allow threading) for 32″ to 80″ OD, 7″ Z-axis stroke (optional upgrade to up to 24″).

- RMT PSM-24E Pipe Spool Master™ CNC pipe elbow beveling, boring, and facing machine (threading is available with a control upgrade) for up to 24″ OD. Includes powered CNC rotary indexing vice.

- RMT PSM-36E Pipe Spool Master™ CNC pipe elbow beveling, boring, and facing machine (threading is available with a control upgrade) for up to 36″ OD. Includes powered CNC rotary indexing vice.

- RMT PSM-TGB-14 Pipe Spool Master™ CNC threading, grooving, and beveling machine for pipe up to 14″ in diameter. 16″ Z-axis stroke (optionally expandable up to 24″).

- RMT PSM-TGB-24 Pipe Spool Master™ CNC threading, grooving, and beveling machine for pipe with a diameter of just over 24″. 23.6″ Z-axis stroke

To be very literally on the cutting edge of tube and pipe fabrication, consider a tube cutting fiber laser from the RMT KYSON™ Series. With up to five axes of control, these extremely precise fiber lasers can work with a variety of profiles, including round tubes, ovals, square tubes, angle iron, and more. Currently available models can process workpieces with diameters up to 10″ (in round tube) and lengths over 20′, and some models feature fully automatic loading and unloading systems.

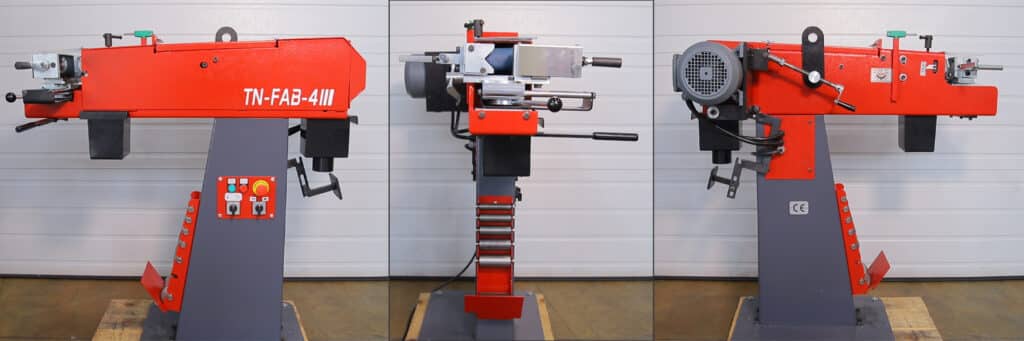

For notching your pipe, nothing does the trick quite like an RMT TN-FAB™ Series Tube Notcher and Sander. This versatile all-in-one machine combines a tube notching and coping grinder, a deburring belt sander, and a bench grinder. The currently available model, the RMT TN-FAB-4™, has three stations that utilize the machine’s spinning sanding belt for the various operations. Seven interchangeable mandrels between 1″ and 3″ are included with this 4 HP dual-speed machine.

Putting a bend in a length of pipe has never been easier since the introduction of the RMT TPB-SERVO™ Series of CNC tube and pipe bending machines. User friendly and easily programmed, the five-axis TPB-SERVO machines provide complete control over each bending operation. Currently available models include:

- RMT TPB-SERVO™ 5X1.5 Tube and Pipe Bender. 1.5″ maximum pipe diameter.

- RMT TPB-SERVO™ 5X2.5 Tube and Pipe Bender. 2.5″ maximum pipe diameter.

If your shop welds or fits up pipe, try a tiltable pipe rotator from the RMT W-TRP™ Series. Your welders no longer need to work their way around a pipe—these ergonomic machines bring the section needing welding to them for less fatigue and greater safety. RMT pipe rotators clamp the workpiece securely and rotates it well above the ground to accommodate pipes with elbows or large flanges. All models in the series have a tilting angle of up to 45° both forward and back.

Available machines include:

- RMT W-TRP 12™ with a pipe capacity of 1″ to 12″ and a weight capacity of 2200 lbs.

- RMT W-TRP 24™ with a pipe capacity of 2″ to 24″ and a weight capacity of 4400 lbs.

- RMT W-TRP 40™ with a pipe capacity of 4″ to 40″ and a weight capacity of 6800 lbs.

Should you wish to roll your own lengths of pipe out of plate metal, Revolution Machine Tools should always be your first call, offering as they do over 100 models of RMT plate rolls. The R-ECO™ Series of motorized initial pinch three rolls are perfect for sheet metal work from 28 gauge to 3/8″ in thickness on workpieces from 3′ to 10′ in length. The R-SMART™ Series of planetary-type hydraulic four rolls are ideal for 1/8″ to 1-3/4″ thick plate in lengths from 2′ to 30′. For the big jobs, the R-GIANT™ Series of rectilinear-type hydraulic four rolls are in order, with their 3/4″ to 6″ capacities and 6′ to 30′ bending lengths. Finally, the R-HYBRID™ Series of variable geometry hydraulic three rolls (planetary configuration) are just right for projects that require heavy bending force, with a top roll that functions like a press brake ram and bottom rolls that move horizontally, much like an adjustable press brake V-die. The hybrid machines work with bending lengths from 8′ to 20′ and plate thicknesses from 3/8″ to 12″. (If you want to bevel your plate before you roll it for easier welding afterwards, be sure to also check out the RMT PBV-FAB™ Series of plate beveling machines.)

To offer customers even more options beyond their RMT machines, Revolution Machine Tools has partnered with Jae Won Industrial Machinery to carry their extensive roster of steel pipe machinery, including their spiral pipe mill lines, coating machines, and JCO press bending lines.

In addition to the sizes of machines listed above, RMT also offers custom machines with larger capacities or designed for specialized projects, so please talk to an RMT machinery consultant about your exact needs. (Note that due to ongoing product development, all specifications listed herein are subject to verification by the customer prior to purchase.)

The Revolution Machine Tools Advantage

Whatever you do with metal, do it better with a machine from Revolution Machine Tools. Along with precision machines for virtually any metalworking task at hand, RMT treats their customers as partners, helping them with everything from suggestions for shop layout to expedite workflow to a service team that is on call around the clock. Please give the RMT team a call today for a competitive quote on your next metal fabrication solution and see for yourself the Revolution Machine Tools advantage.