Picking the Right Bandsaw

“I’m going to buy a horizontal bandsaw for my shop,” the new metalworker told his fabricator friend one evening at dinner.

“What kind of a bandsaw?” the friend asked.

“A metal-cutting saw, of course,” said the novice.

“Yes, but there are many kinds. The first questions you need to ask are what metals you are going to cut and how big of a workpiece you will need to accommodate.”

“Well, I’d want to get something that could handle just about anything.”

The fabricator smiled and said, “You’ll need to narrow it down a bit more, and there are lots of other factors to consider. For example, do you need variable blade speeds?”

“Uh, sure.”

“Do you need the saw to be able to miter?”

“Um…”

“What about bundle cutting?”

The new metalworker just gave him a blank stare.

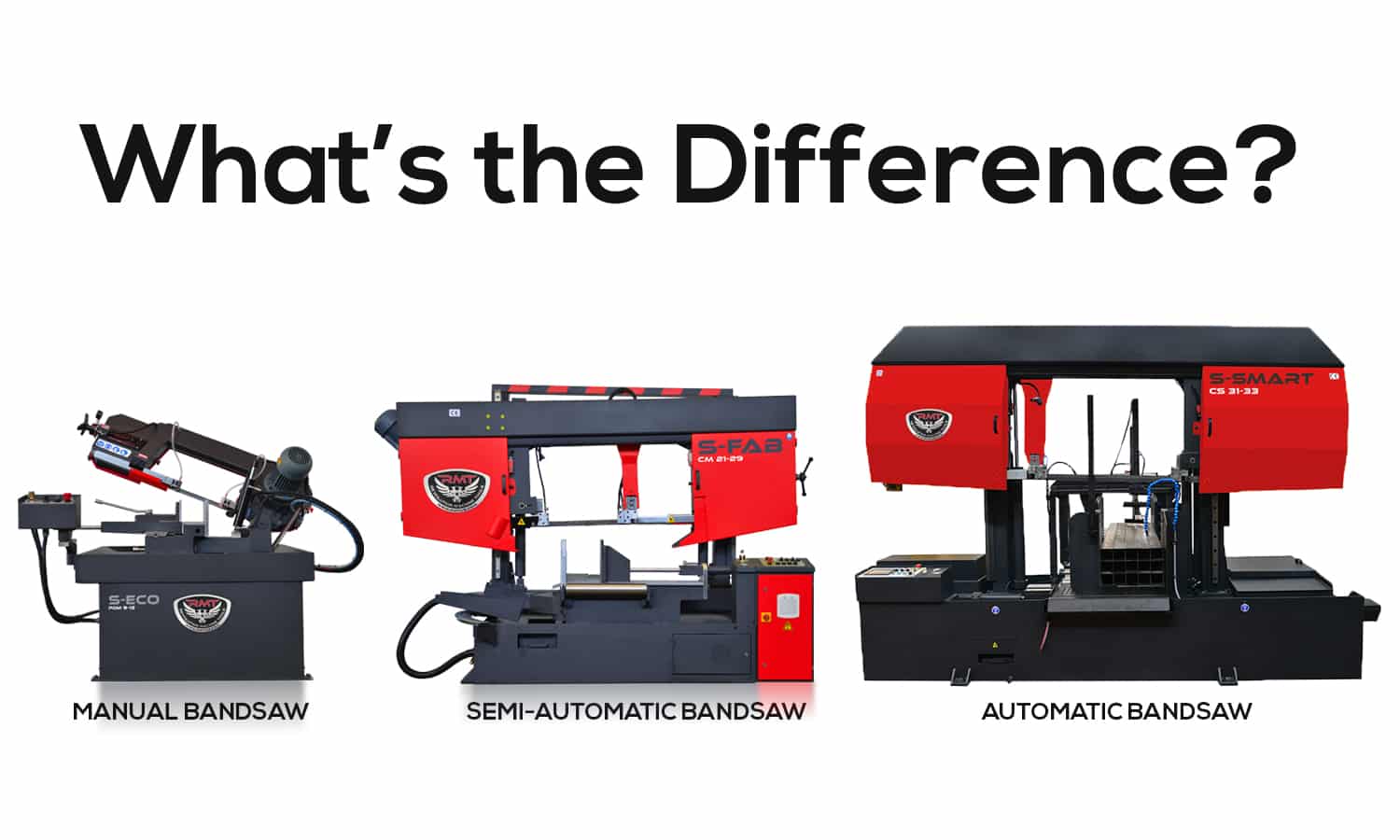

“Let’s just start with how the saw operates. As a beginner, you won’t need anything as fancy as an automatic bandsaw and can probably get by with just a manual.”

“You mean like a car transmission?”

“Not exactly,” the fabricator replied with another smile. “Let me explain the differences between manual, semiautomatic, and automatic bandsaws.”

He knew it was going to be a long evening.

Manual Bandsaws

Manual bandsaws are the most basic type of horizontal bandsaws. While gravity is often what feeds a bandsaw blade down into a workpiece while cutting, some force is needed to lift the saw head back again. A manual bandsaw requires the operator to physically lift the head after each cut. Manual bandsaws are almost always pivot style saws, meaning their heads are hinged at one side and come down at an angle like a paper cutter. The operator then lifts the saw head back up when the cut has been made.

Despite the additional physical exertion, manual bandsaws are much less expensive than semiautomatic or automatic saws and are ideal for the fabricator who only cuts small diameter jobs or who needs a bandsaw that can be easily transported to a worksite.

Semiautomatic Bandsaws

Semiautomatic horizontal bandsaws utilize hydraulic pistons to raise and lower their heads, saving operators the physical stress of having to raise the head back up after the completion of the cut. Ideal for the fabricator who only needs to make a few cuts in a workpiece, semiauto saws are often designed to complete other tasks in the cutting operation at the flip of a switch, such as clamping the material, starting the blade, running the coolant, and beginning the downstroke at a specific feed rate. The operator must manually reposition the material for the next cut, but most other operations are automatic.

A hydraulic down feed provides consistent pressure during an operation, allowing a more accurate cut (not to mention putting less wear on the blade than would likely be the case with an overeager operator who might force the head downward too harshly during the cut). A semiautomatic band saw can either be a pivot style or a dual column design, meaning the head raises and lowers on columns on either side of the head for more stability. Even though there is a higher price tag for a semiautomatic horizontal bandsaw, they are labor-saving devices that reduce operational costs.

Automatic Bandsaws

Where a semiautomatic bandsaw will make a single cut, raise the head back up, then stop, an automatic bandsaw will just keep working, even if the operator walks off. Following a set program, the saw will automatically feed material into position and then continue to make cuts. It only stops when the program is complete, the material runs out, or if the blade happens to break (which is automatically detected by the machine).

An automatic horizontal bandsaw is equipped with a vice that allows the material to be advanced in the saw between cuts. It will either be a shuttle vice, which travels to pull the material into place in the saw, or the more common powered roller vice, which features vertical driven rollers embedded in each side of the vice to move the material into position. The operator loads the material, sets a limit switch or encoder for the exact length of the cut, enters the number of parts into the controller, and starts the machine. The parts are then cut and collected in a bin automatically, saving the shop time and labor.

While a pivot-style saw can be automated, most automatic bandsaws designed for production work will have a dual column design, especially in the case of CNC bandsaws. CNC automatic bandsaws feature user-friendly controls that can store dozens—or hundreds—of multiple-step programs while optimizing the processing of each workpiece by interacting with multiple sensors in the machine. (It should be noted that while some manufacturers will label their regular automatic saws as “fully automatic,” many will reserve that term for their CNC bandsaws, making a distinction between the automatic and fully automatic bandsaws that they offer.)

Designed for high-volume facilities that need to produce multiple workpieces at the same length, automatic horizontal bandsaws are extremely efficient and accurate machines.

Automating Your Bandsaw Purchase

Make your next bandsaw purchase less of a difficult process by partnering with a trusted machine tool advisor who can guide you through the steps of evaluating what type of bandsaw would be ideal for your current and upcoming projects. The sales consultants at Revolution Machine Tools would be happy to demonstrate the advantages of the manual, semiautomatic, automatic, and CNC bandsaws sold by RMT and provide you with a competitive quote on the machines that best fit your operation.