The Heavyweight of Light Welding

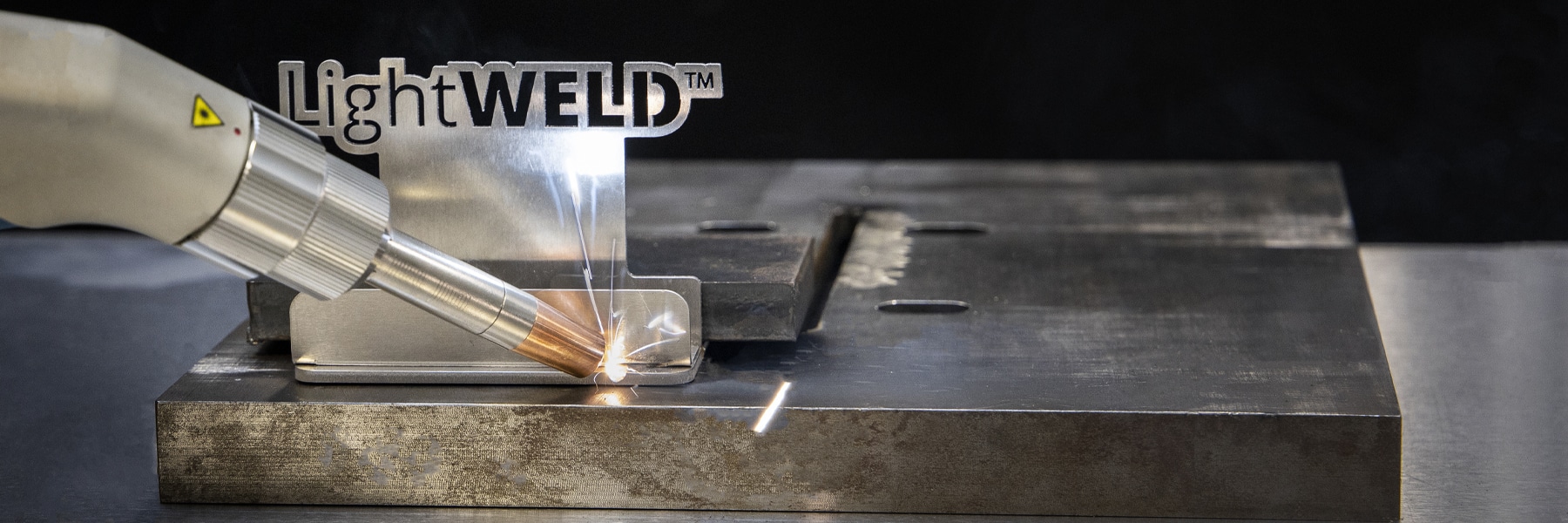

Revolution Machine Tools partnership with IPG Photonics allows RMT customers access to the LightWELDTM line of fiber laser welders; including the LightWELD XR laser. The three models in the line give fabricators a faster and more efficient way of welding their parts together than traditional welding methods can provide.

For cost-conscious metalworkers, the LightWELD 1500 can weld up to about 5/32″ (0.157″ or 4 mm) of mild steel, stainless steel, galvanized steel, and aluminum (3 series and 5 series). For those needing pre-weld cleaning and/or post-weld cleaning capabilities added to those capacities, an upgrade to the LightWELD XC is available.

For the serious fabricator, however, the powerhouse of the bunch—the LightWELD XR fiber laser welder—is the one and only choice.

Capabilities of the LightWELD XR Fiber Laser Welder

Along with pre-weld and post-weld cleaning capabilities, the LightWELD XR provides the power to weld a variety of different metals:

- Aluminum (3 Series) – 1/4″ (6.35 mm)

- Aluminum (5 Series) – 1/4″ (6.35 mm)

- Aluminum (6 Series) – Nearly 1/8″ (0.118″ or 3.0 mm)

- Copper – Nearly 5/64″ (0.079″ or 2 mm)

- Galvanized Steel – 1/4″ (6.35 mm)

- Mild Steel – 1/4″ (6.35 mm)

- Stainless Steel – 1/4″ (6.35 mm)

- Titanium and Nickel Alloy – Over 3/16″ (0.197″ or 5 mm)

The LightWELD XR can also weld dissimilar metals together, like copper and aluminum.

What the Heck is Pre-Weld and Post-Weld Cleaning?

Pre-weld cleaning is a process to burn away any impurities that could wind up in the weld pool. Contaminants such as rust, paint, or oil could increase the porosity (the percentage of void space) in the weld pool or otherwise cause defects in it.

Post-weld cleaning is a final pass to eradicate any new debris and the soot left behind by the welding process. It can also improve the look of the weld by removing discoloration or other visual evidence of localized heating.

The LightWELD XR fiber laser welder provides high-frequency peak power of 2500 W for pre-weld and post-weld cleaning, with a cleaning scan width of more than half an inch (up to 0.591″ or 15 mm).

When Your Welding Needs a Wobble or a Wire

The LightWELD XR offers both wobble welding and wire welding for those fabricators who seek these features.

The built-in wobble welding function—which oscillates the fiber laser beam back-and-forth at various frequencies—is used to accommodate wider seams to just over 3/16″ wide (0.197″ or 5 mm), as well as to create more aesthetic welds. The wobble function is also helpful for welding parts with poor fit-up. The LightWELD XR has optimized, preprogrammed wobble parameters installed and allows on-the-fly wobble welding control at adjustable frequencies up to 300 Hz.

The optional wire feeding package allows laser welding on poorly fit-up parts. The welding wire not only serves as the electrode in the welding process, but it also becomes filler metal that joins the molten weld pool formed from the melted base metal.

More Benefits of the LightWELD XR Welder

The LightWELD XR handheld fiber laser welder can be operated at the maximum 1500 watts of laser power for 100% of the duty cycle. It can weld parts using all weld joint types, such as butt, corner, edge, lap, and tee. It delivers a beam with higher brightness to weld an extended range of materials, including reflective materials, and do so without part deformation.

Other features of the LightWELD XR include:

- It comes preloaded with optimized welding parameters for the most common materials and thicknesses. The operator can adjust the power up or down to match their travel speed and desired penetration and can save those settings for future work. Regardless of the operator’s skill level, the built-in presets provide the proper settings for high-quality welds time after time.

- Learning is a breeze with the LightWELD XR. Compared to the months or even years it can take to master MIG and TIG welding, the operation of this fiber laser welder can be learned quickly, allowing new users to make high-quality welds in a few hours’ time.

- Its travel speed is up to four times faster than traditional methods like TIG and MIG welding. Fixturing the workpiece is simpler (and often not even necessary), and productivity is further increased, as the post-weld cleaning reduces or eliminates the need for finishing work such as grinding or sanding.

- Since most operations are done without consumables and produce minimal splatter, the LightWELD XR is perfect for welding in any position, such as upside-down welding.

- It offers five modes of operation to accommodate the fabricator’s needs: continuous wave for faster welding with maximum penetration; pulsed welding for less heat input; tack mode for identical tack welds; stitch mode for repeated tacking or overlapping welds; and high peak power mode that provides short bursts of high power for penetrating reflective metals.

Choose RMT for All of Your Fabrication Needs

With the addition of IPG Photonics’ line of LightWELD fiber laser welders, Revolution Machine Tools puts yet another fabrication technique into the hands of its customers. From band saws, shears, and fiber lasers for cutting apart workpieces, to laser welders for stitching them back up again, to machines for bending, rolling, and otherwise forming metal, RMT covers the gamut of fabrication processes.

Call RMT today for more information about the LightWELD XR fiber laser welder or any other RMT product and learn how Revolution Machine Tools can give you a better return on your metalworking machine investments.