When Only a Cold Saw Will Do

The bandsaw will probably always be a fab shop’s go-to metal cutting machine, mainly because of its flexibility in being able to handle a wide range of material types and sizes. For certain jobs, however, a cold saw with its solid circular blade, such as the S-Genius HSC4 Cold Saw would be a preferred choice. Precision job shops will often opt for the accuracy that a cold saw with its tight tolerances will provide, especially for cutting smaller parts. Cold saws leave an extremely clean cut on the finished part, and—as their name implies—cut a lot cooler than bandsaws do, a benefit when working with certain heat-sensitive materials.

Revolution Machine Tools, while offering over two dozen models of bandsaws to handle most jobs encountered by their customers, also made sure to include in their inventory a half-dozen different cold saws for those whose work might require one.

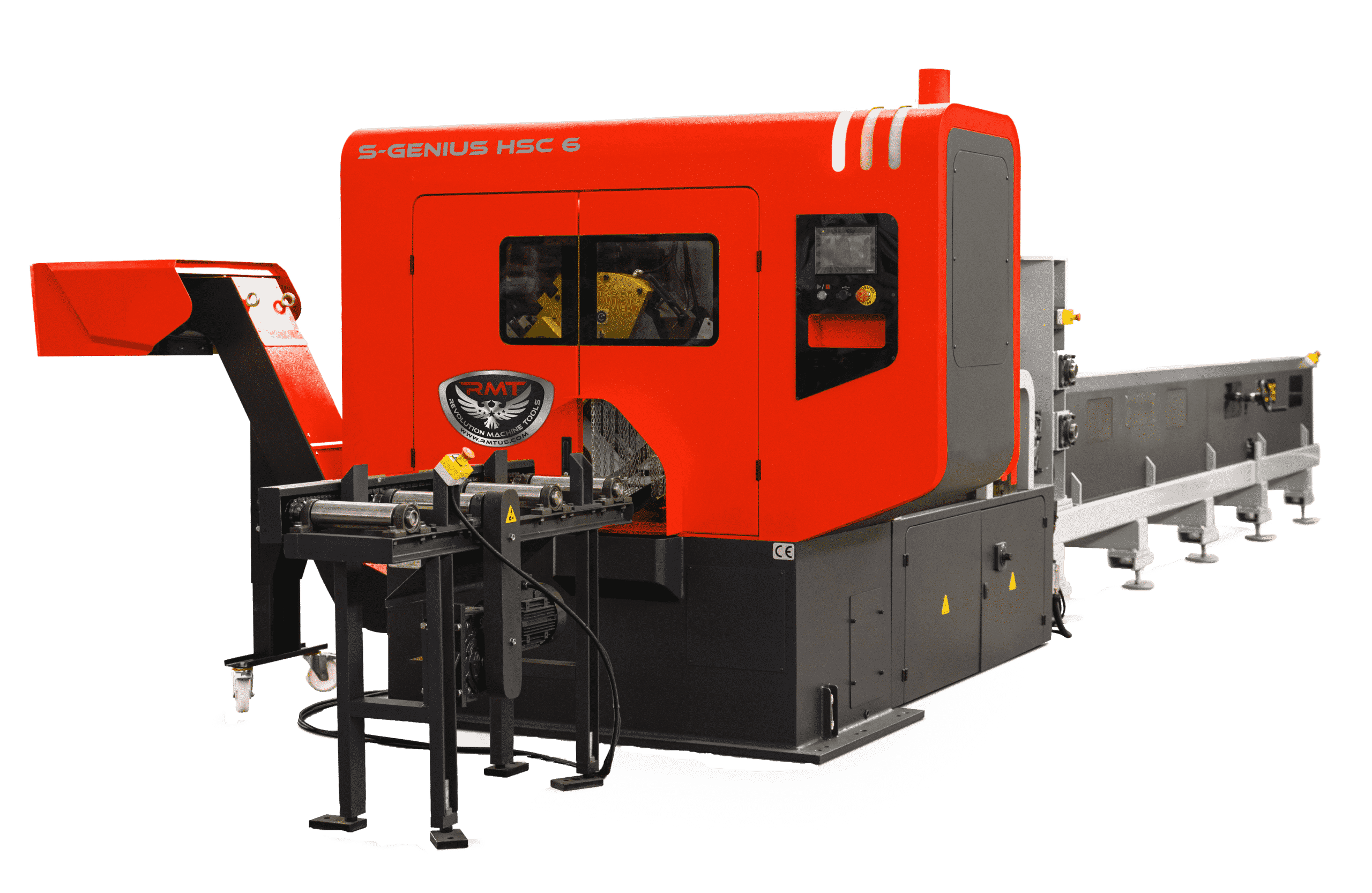

Like most machines they sell, RMT’s cold saws are divided into different series for easier classification. The S-FAB CLD series includes three models of semi-automatic heavy-duty circular cold saws, with round cutting capacities up to 4.5″. For more demanding users, RMT also offers the S-GENIUS HSC series of automatic servo feed cold saws. The saws currently in this series are:

- The HSC3 with a round cutting capacity up to 3″.

- The HSC4 with a round cutting capacity up to 4″.

- The HSC6 with a round cutting capacity up to 6″.

Our focus here is on the HSC4 cold saw, by far the most popular saw in the series.

Features of RMT’s S-GENIUS HSC4 Cold Saw

With a round cutting capacity from 0.78″ to 4″, the HSC4 cold saw was designed to provide the most efficient cutting of stock and tubes available in the industry today. It features an extremely accurate 14″ high speed cold saw blade that can make thousands of cuts before ever needing sharpening or replacing. The blade costs pennies on the dollar compared to standard bandsaw blades that break or wear out performing the same tasks.

This automatic servo feed saw allows up to 31.4″ of part feeding per stroke. Adding the optional 20′ automatic material handling table greatly improves a shop’s workflow and is recommended by Revolution Machine Tools to their cold saw customers. The automated table loads the material for the operators, allowing them to focus on each cut, increasing productivity with greater part repeatability. The combination of the HSC4 cold saw with the automatic material feeding table creates the perfect precision-cutting workhorse for any high-volume job shop.

Standard equipment for the HSC4 cold saw includes: a saw blade brush, a chip conveyor to keep the work area clean, automatic hydraulic clamping, a hydraulic vice with a maximum 4.7″ opening, an adjustable blade stroke, and an enclosed cabinet for safety and style. The HSC4 is designed with carbide blade guides to prevent wandering, further improving accuracy on every cut. An automatic discharge tray is programmed to feed the finished parts into the correct bins.

Like most machines sold by RMT, the HSC4 can be run by a single operator, thanks to the handy touchscreen interface on the control panel. The user-friendly interface is programmable for batch cutting up to 100 jobs with 50 sequences per job.

The S-GENIUS HSC4 sports a 15 HP main motor and a 3 HP hydraulic motor. It features a heavy-duty gear box and has an inverter and a speed controller, with cutting speeds from 131 to 918 feet per minute. Revolution Machine Tools utilizes the highest level of world-class controllers and electrical components on this and all their machines, not only helping to ensure quality production, but also making it easy for customers to find replacement parts off-the-shelf wherever they live.

Formerly an optional add-on, each HSC4 saw from RMT now comes standard with a micro-spray cooling system. This high-end lubrication system increases the life cycle of the machine while helping deliver a smooth, cool cut. An optional upgrade preferred by many customers of RMT is a DropsA air/oil clean lubrication system. The hybrid air/oil system injects small droplets of oil at regular intervals into a continuously flowing stream of air. This minimalistic approach to lubrication from DropsA eliminates the mess of regular saw coolant while providing a very effective solution for cooling and lubricating the saw, delivering precise amounts of oil exactly where it is needed.

A standard two-year warranty and the availability of RMT’s in-house service and parts teams add even more peace of mind on top of RMT’s guarantee of quality workmanship.

Fast, accurate, and easy to use, the S-GENIUS HSC4 cold saw is a cost-effective way to deliver precision cuts in metal, time after time.

A Customer-Approved Cold Saw

Speaking of the S-GENIUS HSC4 cold saw from RMT, a customer from the Midwest commented, “Kyle Jorgenson and his crew set us up with this machine, and it has increased our productivity in our saw bay.” Referring to a crate of short, solid cylinders, he continued, “This was a repeat order for us. We always cut a thousand pieces through our bandsaw and that job would typically take three and a half days and two bandsaw blades. This job on the RMT cold saw takes four hours now for a thousand pieces of 2-5/16″ cold rolled round 1045 [steel]. [It has] excellent productivity.”

Picking up one of the small blanks, the customer added, “These parts go into a CNC lathe and get the center cored out and faced to turn into a bushing. When we were cutting them on the bandsaw, if the condition of the blade wasn’t observed, the cut would get out of square, and we’d have chucking issues in our machining centers. Now that we’re using the RMT cold saw, that’s no longer an issue.” (Finn-Kool Testimonial video regarding the RMT High Speed Carbide S-GENIUS HSC 4 Cold Saw)

Say, Why Don’t You See a Saw from RMT Today?

The metalworking machinery consultants at Revolution Machine Tools are always available and eager to give interested customers a demonstration of the RMT cold saws, bandsaws, and other metal fabrication machines they offer. If you are looking for the very best solution for working with metal for your projects within your budget, the experts at RMT will provide the answers you need. Give them a call today and get a competitive quote on your next cold saw.