Selection Is Everything

Sometimes you need to quickly replace a press brake that’s permanently gone down to get back to an important job and you don’t have the luxury of being picky. Most of the time, however, you can invest the proper amount of preparation in planning such a significant purchase for your shop.

A quality press brake distributor won’t treat you like a naïve country bumpkin who just arrived at a used car dealership in the big city and try to sell you “a real beauty” that he’s been wanting desperately to move from his lot. The foremost equipment wholesalers and retailers will offer a wide array of precision machines with a range of different features and options to satisfy the needs of the most discriminating metal fabricators.

The best dealers will also take the time to understand you as a customer and learn the ins and outs of your operation and production to suitably match you to the press brake that will bring you the best return on your investment and be a boon to your business in coming years.

Revolution Machine Tools is one such press brake seller, a company that offers a massive lineup of quality machines yet sits down in person with each customer to evaluate their exact needs and provide them with the solution that best works for their situation.

What Size Press Brake Do You Need?

Revolution Machine Tools lists nearly five dozen different press brake models with capacities to fit just about any standard fabrication job (and the ability to produce custom brakes to meet the requirements of the non-standard ones).

Bending force capacities run from 50-tons to a whopping 20,000-tons, while bending lengths in standard models run from a 5′ long electric brake to 40′ long hydraulic machines. In addition to longer custom models, RMT press brakes are designed to be run in tandem, meaning that two (or three, or even four) brakes can be aligned side-by-side for longer jobs and be operated simultaneously through one CNC screen.

What Style Press Brake Do You Want?

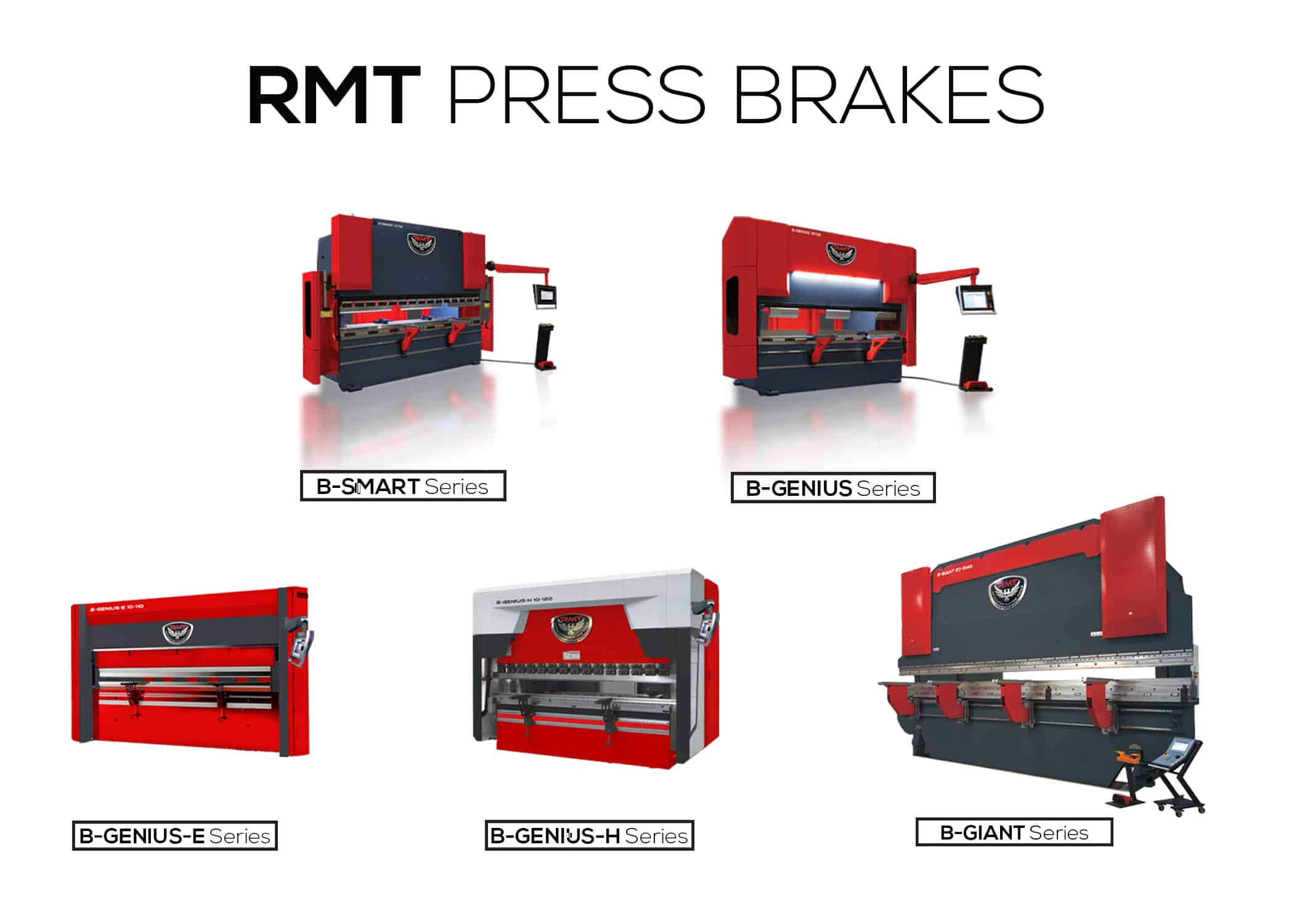

The “standard” press brakes from Revolution Machine Tools can be found in their B-SMART series of precision hydraulic machines that feature a 3-axis CNC (Y1, Y2, X) and can be upgraded to 5-axis capabilities. Models feature bending lengths from 6′ to 20′ and bending capacities from 70 to 660-tons.

For those needing even greater accuracy, a step up is the 7-axis B-GENIUS series of hydraulic brakes which can be expanded up to 16+ axes of control. Models feature bending lengths from 6′ to 20′ and bending capacities from 70 to 660-tons.

Want to go green with an electric press brake? RMT offers their 4-axis B-GENIUS-E series that is upgradeable to include 5 additional axes. Models feature bending lengths from 5′ to 10′ and bending capacities from 50 to 120-tons.

For the eco-conscious and cost-conscious fabricator who just can’t bring himself to give up the bending power of a good hydraulic brake, RMT provides their 7-axis B-GENIUS-H series of hybrid press brakes. These hydraulic/electric machines are available in models with bending lengths from 8′ to 20′ and bending capacities from 110 to 300-tons.

When a big job is needed and tandem brakes just don’t have the necessary tonnage, RMT’s 7-axis B-GIANT series of hydraulic press brakes are up to the job. Available up to 14+ axes of control, the B-GIANT machines feature bending lengths from 10′ to 40′ and bending capacities from 660 to 20,000-tons.

Fabricators looking for the very best press brake performance on the market today can find exactly what they are seeking with any one of RMT’s highly engineered and finely crafted metal-bending press brakes.

What Press Brake Options and Accessories Would You Like?

If you look at a specification list for any press brake from Revolution Machine Tools, it will take you more than a minute to read through every standard feature and included accessory.

While RMT machines come fully loaded, the list of options is just as hefty. From switching out the standard manual safety laser for a motorized version to upgrading the CNC control unit, RMT will add all the bells and whistles that a fabricator could imagine. They will even send your next brake to you from the factory painted in your company’s custom colors if you want.

Your Personal Press Brake Concierge

With nearly 60 models of press brakes to choose from, Revolution Machine Tools’ machinery consultants are available to guide you through every step of your decision-making process, giving you frank and clear answers to all your questions.

In addition, RMT will request to perform an onsite evaluation of your facility, an assessment of your production area that will help determine how well any proposed press brake will work with all other facets of your operation. The rigging, positioning, and installation of the machine will be planned, along with a detailed listing of any requirements that must be completed prior to delivery, such as running proper power and your preferred arrangements for waste removal.

Regardless of your metal-bending desires, the team at RMT will assist you in picking the perfect press brake to improve your production.