The Most Important Press Brake Parts

If you asked some random worker in a metal fabrication shop what the most important part of a press brake is, you might get an answer like “ram,” “hydraulic system,” or “back gauge.” A brand-new press brake operator might even answer “CNC control.” A veteran fabricator, however, would almost certainly respond: “tooling.”

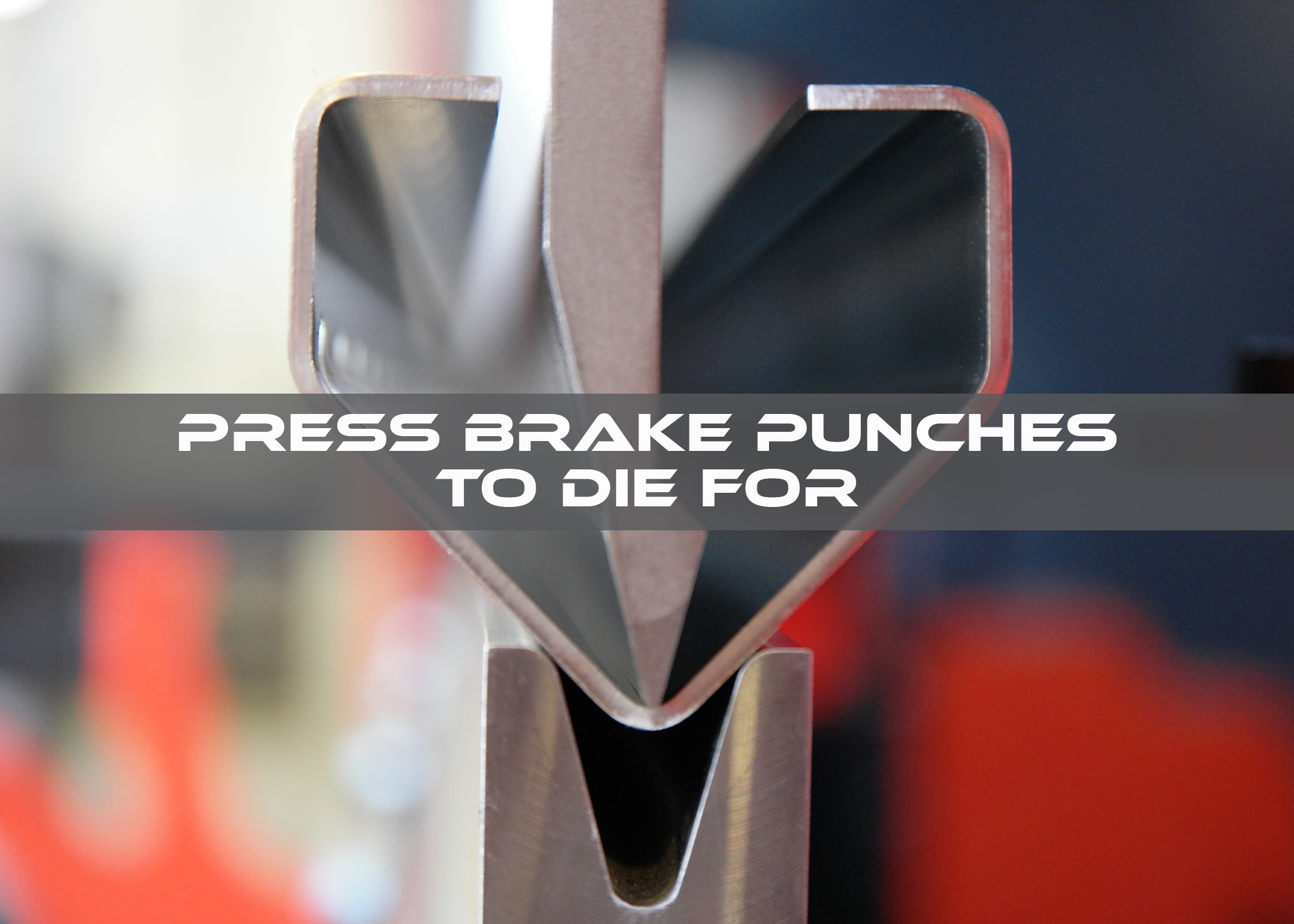

While not technically part of the press brake itself, the tooling—press brake punches and dies—are the elements that touch and interact with the metal being shaped. The machine provides power and measurement, but all of that is to apply the tooling to the metal to make the required bends.

Choosing the Best Press Brake Tooling

The most accurate and powerful press brake on the market is worth little if it is equipped with substandard tooling. Investing in high-quality punches and dies is essential for achieving consistent and precise results while maximizing tool life. Quality tooling may be initially more expensive but has continually proven to be cost-effective in the long run, since it reduces operational downtime, tooling replacement costs, and workpiece reworking.

As you begin the process of selecting tooling for your press brake, some preliminary steps include:

- Knowing Your Press Brake. Familiarize yourself with the capabilities and limitations of your specific machine. Especially note its tonnage, bed length, and stroke length. This information will aid in determining the suitable sizes and types of tooling for your brake.

- Verifying Compatibility and Interchangeability. Check if the tooling you are considering is compatible with your press brake. Ensure that the system aligns with your machine’s specifications, such as the clamping system and tooling length. Additionally, consider the interchangeability of tooling components within your existing setup. Having the ability to switch between different tooling configurations quickly can improve efficiency and productivity.

- Recognizing Your Job Requirements. Before diving into the selection process, it is essential to understand your specific bending requirements. Consider factors such as the material type, thickness, flange lengths and widths, and bending angles. Different tooling configurations are designed to handle various applications, so having a clear understanding of your needs will help you make an informed decision.

- Understanding Your Material. The metal being bent plays a significant role in tooling selection. Different materials have varying characteristics, including hardness, ductility, and springback. Ensure that the tooling you choose is designed to handle the specific material you are working with. For example, using tooling designed for soft aluminum on stainless steel could result in poor bending quality or premature wear.

Partner with Revolution Machine Tools for Punches and Dies

For the very finest in press brake parts and tooling, look no further than Revolution Machine Tools. Nestled in the foothills of the Rocky Mountains, RMT opened its doors years ago with the pledge to offer the highest quality press brakes and other metal fabrication machines to its metalworking customers in the US and beyond.

Revolution Machine Tool press brakes have been designed by their engineers utilizing the latest cutting-edge technologies to provide superior accuracy and performance over the course of each machine’s long life. To complement their brakes, RMT has selected premium tooling to pair with each machine. Their press brake customers know they can rely on RMT’s Parts and Tooling Department to furnish them additional or replacement punches, dies, and holders to keep their machines bending with maximum efficiency and precision through the years.

A fabricator doesn’t need to have an RMT press brake on his shop floor, however, to take advantage of Revolution Machine Tool’s outstanding line-up of press brake tool offerings. From the outset, the RMT Parts and Tooling Department has supplied their exceptional punches and dies to fabricators across North America, regardless of the machine they own or where they bought it.

RMT brand American Style tooling is known for its precision and durability yet remains an affordable option for any fabricator. Whether you need a standard punch, a gooseneck punch, an acute punch, or any other configuration, RMT has the solution for your metal bending needs. If your preference is European Style or New Standard Style press brake tooling, RMT can order exactly what you require and have it drop shipped to you. They also sell punch adaptors that allow American or European Style tooling to be mounted in a New Standard Style machine.

RMT’s Parts and Tooling Department offers more than just tooling for your press brake. From consumables like a press brake filter to replacement parts like a limit switch to upgrades like a safety laser system, Revolution Machine Tools stocks everything to keep your press brake running day-in and day-out. RMT also staffs an in-house Service Department with trained service techs who are on call to assist you with any mechanical problems your press brake may suffer, as well as standard scheduled maintenance.

Choosing the best press brake tooling is a critical decision that directly impacts the quality and efficiency of your bending operations. By understanding your job requirements, knowing your press brake capabilities, and partnering with a trusted provider like Revolution Machine Tools, you can make informed tooling decisions. Remember, investing in the right punches and dies will result in improved productivity, reduced downtime, and exceptional bending outcomes for your metal fabrication projects.