A Pipe Fitter’s Dream

Threading pipes to join them for plumbing and other uses dates back to the early 1800s. In the intervening two centuries, many different machines have been developed to assist in threading, grooving, beveling and facing pipe. A plumber’s shop, sprinkler system maker or oil field maintenance facility likely has a fleet of different machines, each in a limited size range and built to perform a specific duty. But what if one machine could do it all, and in a wide range of sizes?

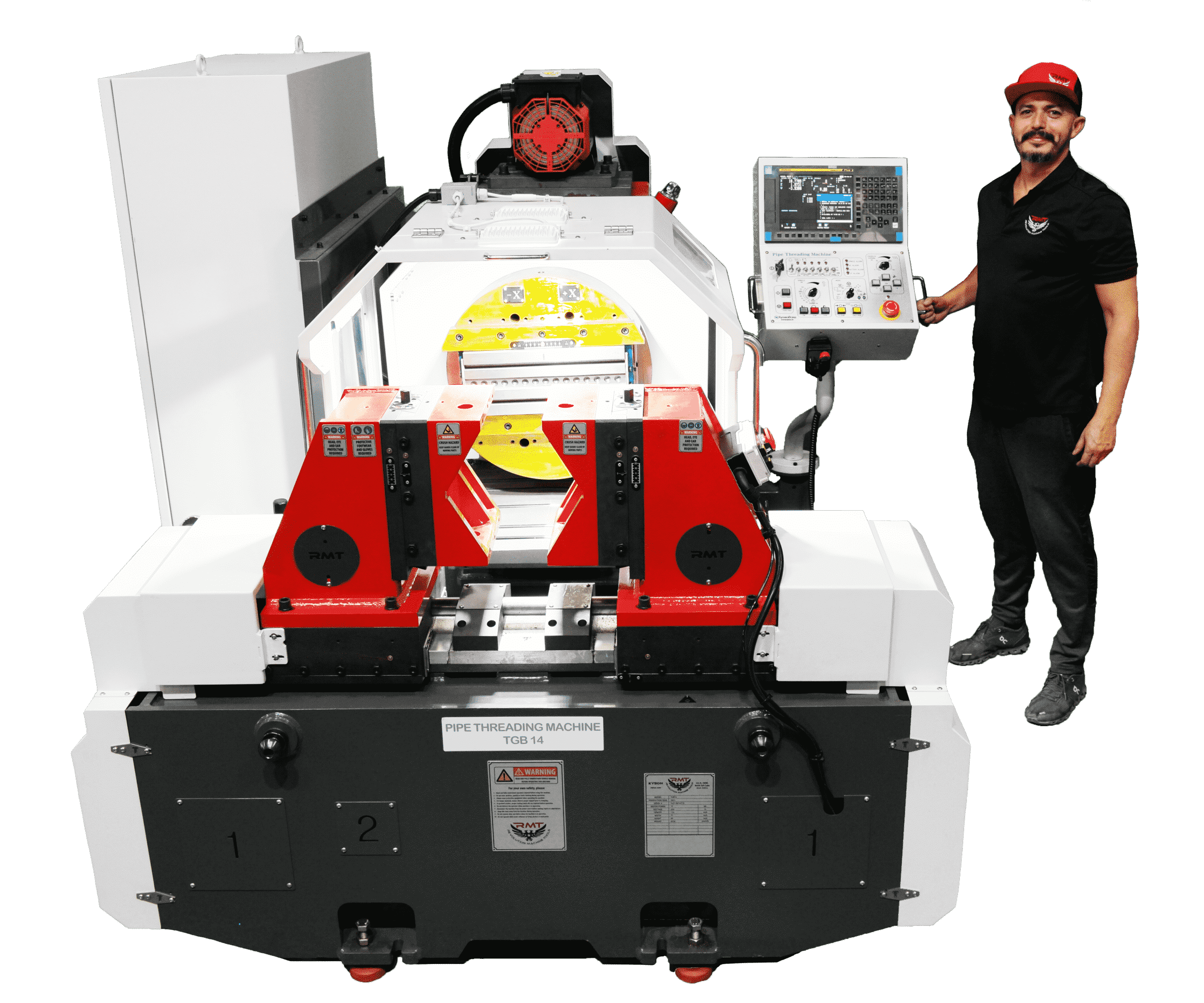

What was once—excuse the pun—a pipe dream, now is a reality, thanks to Revolution Machine Tools’ Pipe Spool Master TGB Series machines. A veritable Swiss Army Knife of pipe fitting tools, these machines literally do it all: beveling, boring, centering, chamfering, drilling, facing, grooving, milling, rounding, tapering, tapping, texturing, thread cutting, threading, turning and weld preparation.

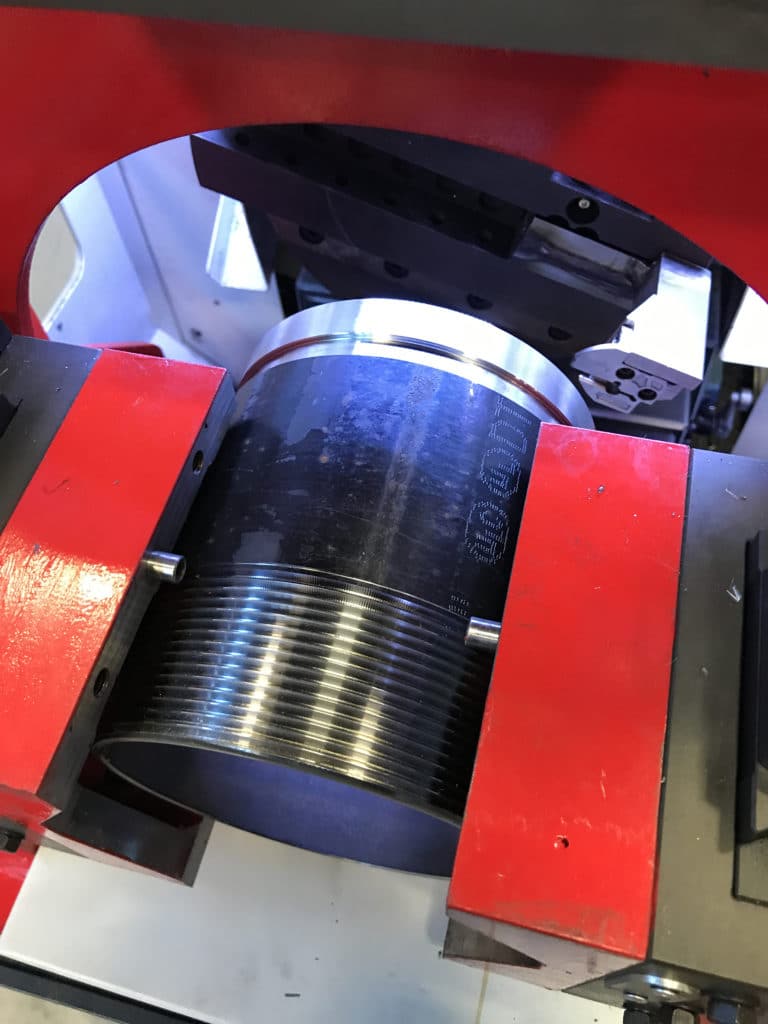

RMT’s Pipe Spool Masters are basically lathes, but unlike any lathes known to metalsmiths of the last century. Instead of rotating the workpiece to facilitate machining, the pipe stays stationary in RMT’s machine and the spindles move left and right along an X-axis while spinning to do all the cutting. The Pipe Spool Masters were already a revolution in pipe beveling, boring and facing, but the introduction of the TGB line—which stands for threading, grooving and beveling—upped the ante with the additional features that make them the only one-stop multipurpose machines of their kind in the industry.

Advantages of the Pipe Spool Master TGB Series

Sporting Fanuc i-Series controls with industry standard Gibbs software, these CNC marvels can be programmed to do whatever their operators need done to a particular pipe, whether it be cutting ID or OD threads, grooving for Victaulic-style couplings or beveling ends to prepare pipes for welding.

Besides the versatility of combining multiple functions in one machine, some of the other advantages that TGB models have over comparable machines include the following.

- Safety is a huge selling point of the TGB. With a regular lathe, having a 20′-long part that’s spinning at upwards of 800 RPM can be a recipe for disaster if something goes wrong. All Pipe Spool Master machines hold the workpiece immobile while the machine itself does all the work, for a much safer operation.

- It’s also a much cooler operation, since only the tool is rotating and not the pipe (RMT’s motto for the machine is “Spin the Tool—Keep it Cool”). While not recommended, parts that aren’t that heavy can even be cut without coolant at a slower rate, as shown in RMT’s demo videos.

- The cost of a TGB machine can be one-fourth to one-third that of a through-spindle lathe.

- Likewise, the footprint of a TGB is much smaller as well, with through-spindle lathes taking up to eight times the floorspace of RMT’s machines.

- If needed, the TGB can be easily converted for mobile operations on a jobsite or out in the oil fields. A user can add a generator to the back of a truck and use a self-leveling trailer to transport the machine, making the necessity of sending a pipe off to a machine shop and waiting for them to finish and return it a thing of the past. (In fact, the staff of Revolution Machine Tools has frequently taken a Pipe Spool Master out on the road to give demonstrations to customers.)

- Unlike a lathe, the Pipe Spool Masters can accommodate pipes of unlimited lengths, with the working end clamped in the machine and the rest supported by a roller table or a crane.

- Models are available to handle virtually any size pipe that is needed, from 1″ in diameter all the way up to 180″.

- Pipe Spool Master machines require very little maintenance on them—routinely changing the oil, greasing the ways and bearings and tensioning the belts keep them running like a charm. (RMT’s service team hasn’t had to fix one in the four years they’ve been selling them.)

- On a standard lathe, once you pull a pipe off, you can’t rethread it because the orientation will be off. TGB machines have up to 24″ of Z-axis back travel. This means that the spindle can be moved back and out of the way so the work can be checked and tested while the pipe is still stationary in the machine. If another 15-thousandths of an inch needs to be taken off, the operator can change the program and take care of it instantly with no difficulty.

- Pipe Spool Masters are much faster than other machines. One customer who owned a competitor’s beveler and was used to a 12-hour operation time was amazed to see a demonstration of an RMT unit where it performed the identical function in just 15 minutes. (He wrote a check for one on the spot.)

- Tooling changeovers can be done rapidly and altering a Pipe Spool Master for a different size diameter goes very quickly as well. For a now-defunct competitor’s machine, it required a six-hour teardown to change from a 2″ to a 4″ diameter. The same change on a Pipe Spool Master takes approximately 10 minutes.

- Easier to set up and easier to run than competing machines, TGB series machines are also more productive in the fact that workpieces can stay in place to have several different operations performed in rapid succession.

A Revolutionary Way to Machine and Turn Pipe

While the classic lathe isn’t going away anytime soon, the Pipe Spool Master TGB Series is rapidly taking its place as the go-to machine to thread, groove, bevel and face pipe. The portability of the machine makes it a must-have in the oil and gas industry, and their affordability makes purchasing one a no-brainer for anyone considering a comparable-sized through-spindle lathe to do the identical functions.

Regardless of the industry or application, Pipe Spool Masters have completely revolutionized the field of pipe fitting in the modern world.