What Is a Pipe Spool Master?

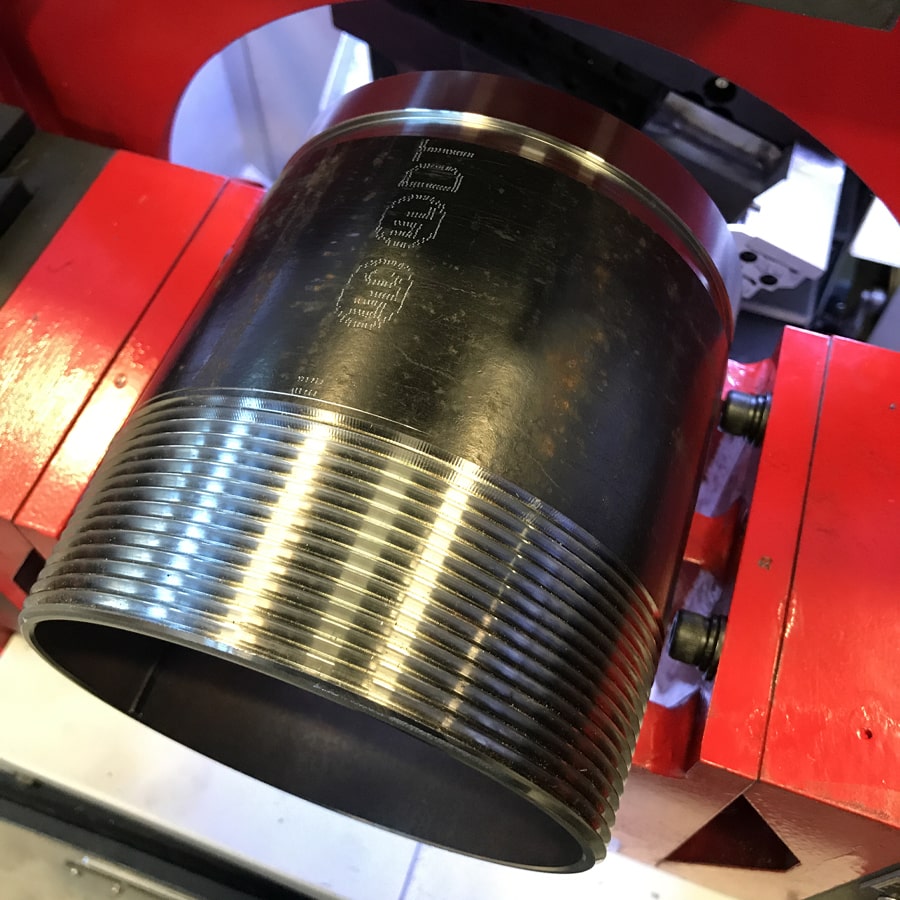

A pipe spool machine is basically a reverse lathe—instead of spinning a workpiece, it keeps the part stationary and secure while using rotating tools, like a mill, to perform a variety of functions like beveling, boring, and facing, in addition to standard threading operations.

Revolution Machine Tools went beyond the competition when they introduced their Pipe Spool Master machines that combine a far wider range of machine shop functions, including:

• Thread Cutting

• Beveling

• Boring

• Centering

• Chamfering

• Drilling

• Facing

• Grooving

• Milling

• Rounding

• Tapering

• Tapping

• Texturing

• Thread Cutting

• Threading

• Turning

• Weld Prepping

These multipurpose machine tools save time and money in pipe shops and are gamechangers in the oilfield maintenance industry where multiple, very bulky machines were previously needed to perform the same functions as a single, streamlined RMT pipe spool machine.

Quick Change Artist

With the pipe clamped and centered in place, the Pipe Spool Master’s facing head does all the work, spinning as it approaches the material, the assembly moving left and right along an X-axis to process the pipe.

RMT’s standard toolholder is a mostly rectangular piece, with nine bolt holes across the front face and two holes going back on either side of the corner holes. This wide horizontal arrangement allows a variety of tools to be mounted in the toolholder.

The tooling can be changed easily and quickly on a Pipe Spool Master, simply by loosening a few bolts along the edge of the toolholder where tool is installed and pulling out the tool. A new tool can be inserted at the same spot, or if a different configuration is needed, the bolts can be completely removed and repositioned to fasten the new tool at the required spot, anywhere along the three exposed sides of the toolholder.

Pipe facing machines generally can accommodate more than one diameter of pipe, though changeovers aren’t always easy. One machine that’s no longer on the market required a six-hour operation to tear down and reconfigure the equipment to switch from working with a 2″ diameter pipe to a 4″ diameter one. The same task can be accomplished in minutes on RMT’s Pipe Spool Master.

The toolholder itself can slide across the X-axis of the head to adapt to a different size of pipe. The operator simply loosens four bolts that secure the back plate of the toolholder to the head, slides the toolholder to the approximate position, centers the tool on the pipe, tightens the bolts, zeros the offset on the pipe and it’s done. A scale mounted to the head shows the limits of how far the toolholder can go to still allow proper movement in the X-axis during the operation. Regarding the procedure, RMT President Kyle Jorgenson commented, “It takes a couple of minutes and you’re up and running.” The Pipe Spool Master has a surprisingly wide range for a single machine.

The toolholder itself can be changed out to a different one, if needed. For example, if an unusually deep bore is required, a longer, thinner toolholder that can fit within the pipe diameter itself can be easily installed.

A Superior Machine

While the ease and speed of tool changeovers on a Pipe Spool Master from RMT gives it a competitive edge over other contenders in the marketplace, the machine has many additional benefits worth noting:

• Affordable | A Pipe Spool Master costs a fraction of the price of a through-spindle lathe needed to process the same size workpiece

• Compact | RMT’s machines have a relatively tiny footprint, taking up a small percentage of the floorspace of an equivalent lathe.

• Fast | Pipe Spool Masters don’t just have quick tool changeouts, they are far faster in many functions than similar machines. For example, a bevel that takes 2-8 hours with classic facing machines can be done in minutes on RMT’s equipment, and with more accuracy and a better surface.

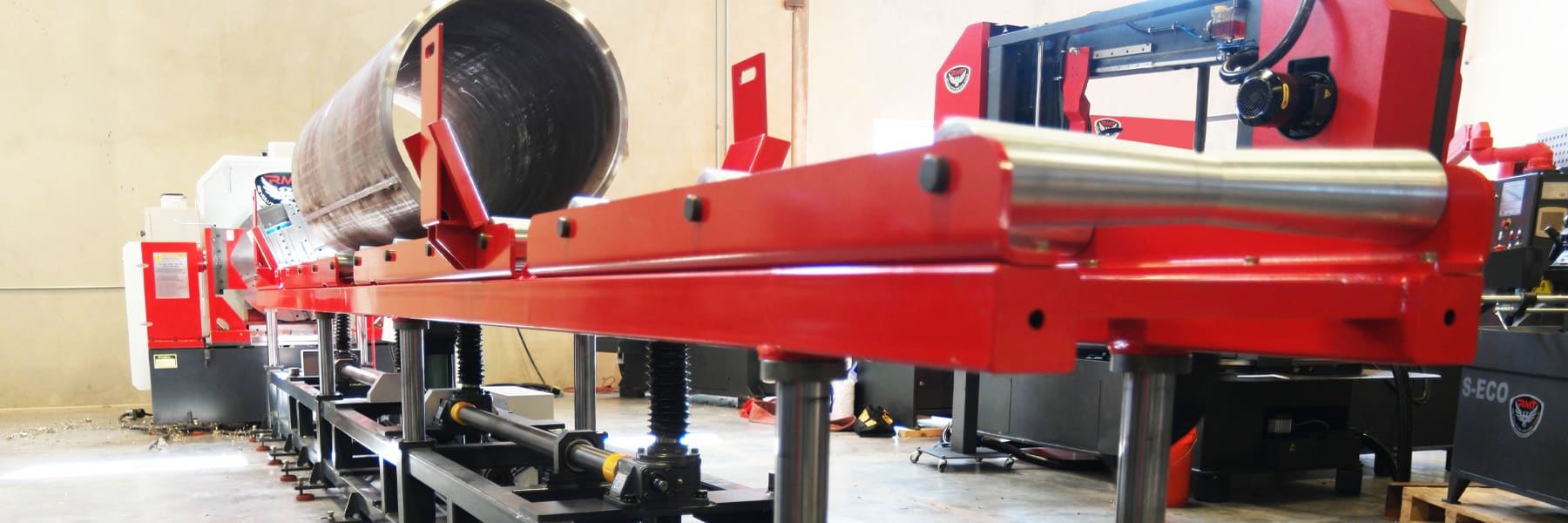

• High Capacity | While lathes are limited in the length of workpiece that they can accommodate, RMT’s machines have no such restriction. With the end of the pipe clamped in place for the operation, the rest can be supported by a crane or roller table. As far as diameters go, models are available to handle any size pipe from 1″ up to a massive 200″ (17 feet).

• Low Maintenance | These high-performance machines keep working year after year, with just routine maintenance needed, such as tensioning the belts, changing the oil, and greasing the ways and bearings.

• Lower Temperature | “Spin the Tool—Keep it Cool” is RMT’s motto, as Pipe Spool Masters run far cooler than traditional lathes that have spinning workpieces.

• Programmable | The operator can program all functions and sequences easily into the intuitive Fanuc CNC control with its Gibbs software.

• Safe | Unlike lathes, Pipe Spool Masters don’t have huge parts spinning at several hundred revolutions per minute, making them far safer for operators and bystanders.

• Transportable | Need to bring the Pipe Spool Master to a jobsite? No problem—the machine can be loaded on a self-leveling trailer and toted along with a generator wherever a pipe needs to be worked on, even out in the oilfields.

A Revolution in Pipe Fabrication

Pipe Spool Masters are amazingly productive machines, allowing several different operations to be performed rapidly, one right after the other, while the workpiece stays clamped firmly in place. The ability to change tooling, diameter sizes and even toolholders easily in a matter of minutes makes RMT’s contribution to the field of pipe fitting a truly revolutionary innovation.