Take Your Laser Cutting to the Next Dimension

It was a thrilling advancement in metal fabrication when the development of CO2 and other metal-cutting lasers (such as tube cutting fiber lasers) allowed a higher tech alternative to plasma and water jet cutting. Another leap forward came with the onset of fiber lasers and their efficiency in cutting sheet and plate metal in two dimensions with high accuracy. Someone had the bright idea that since fiber lasers can cut through plate metal, and since metal tubing is essentially a plate of metal rolled or folded around an empty space, that there must be a way to use a fiber laser to cut tubing.

Instead of having a laser head cut stationary material by moving across a gantry that in turn travels down rails for the length of a machine bed, tube cutting fiber laser heads generally stay in one position with limited movement—such as pivoting at an angle—and the material is advanced to the head and is rotated to be cut or etched. This innovation allows for precision tube production and ornamental work at a level not previously available in the industry.

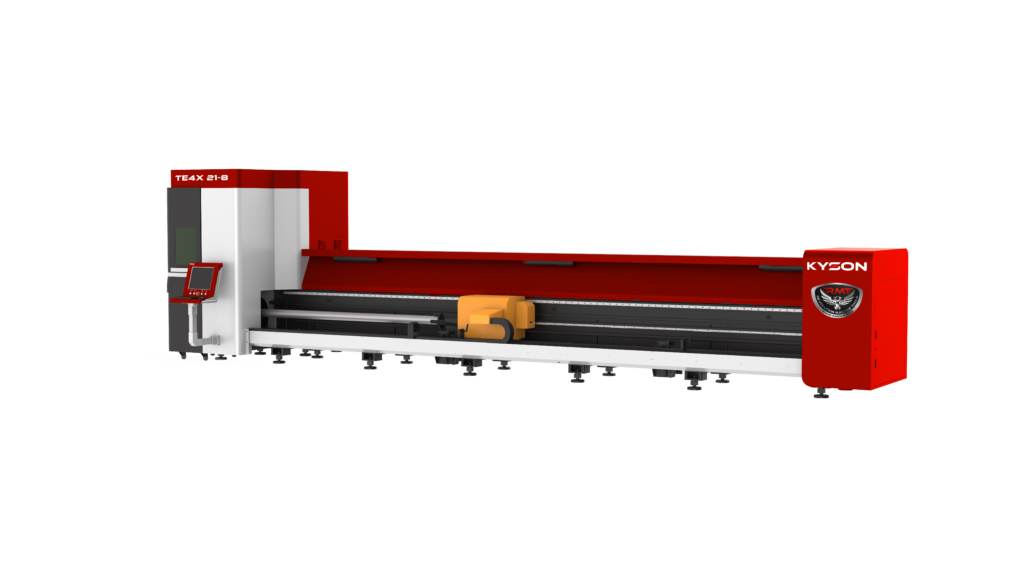

As with all their lines of advanced metal fabrication equipment, Revolution Machine Tools offers tube cutting fiber lasers that are—no pun intended—on the cutting edge of laser metal processing, with state-of-the-art technology combined with intuitive controls that are easy to learn and use, making for very accurate, efficient tube cutting systems.

Precision Cutting

RMT’s tube fiber lasers are extremely precise machines, with an X/Y axis tool position accuracy of ± .001″ and an X/Y axis repositioning accuracy that’s also ± .001″. With up to five axes of control, they are versatile enough to cut not only round and square tubes, but also a variety of tube profiles, including ovals, ellipses, rectangles, triangles, polygonal tubes and even angle iron.

Each machine features advanced tube and profile software designed specifically for multi-axis lasers like these tube cutters. This integrated programming solution optimizes the cutting process by grouping and nesting tasks for greatest efficiency.

Large Capacities, Respectable Power

RMT KYSON series tube cutting fiber lasers aren’t designed for small ornamental work—though they can easily perform that too—they are made for large jobs. Current models can handle workpieces over 20′ in length with diameters of up to 8 or even 10″ in round tube.

The KYSON machines also pack a punch in the power department. While 1500-watt models are available, most of RMT’s tube cutting lasers come as 3000 or 4000-watt machines, with custom models available for order.

These are also fast machines, with some models featuring a moving speed of 460 feet per minute, with up to 1.2G of acceleration.

Sturdy Machine Bodies

The frame of each fiber laser main body is carefully welded to provide stability and be free of defects. Several laser bodies are then placed inside a large furnace at the factory so that they can be stress annealed at 600° Celsius (over 1100° Fahrenheit) under controlled conditions. This removes the material stress that results from the welding process.

Following additional machining, further stress is eliminated from each fiber laser body through two processes: vibrational aging and natural aging. Vibrational aging loosens and relieves internal stress in the material, while natural aging (placing the body outdoors for at least a month) relieves any residual stress through temperature changes in the environment. The entire process provides excellent rigidity in the body, allowing it to be used for at least 20 years without any loss of precision in the laser due to structural deformation.

A five-axis CNC machining center is then used to precisely machine the guide rail, rack and other critical components that require high accuracy. Only world-class parts are used in the construction of RMT’s fiber lasers and other machines.

The Tube Laser You Need

If you are looking to purchase a high-quality fiber laser for cutting tubes and similar structures, you can find the perfect addition to your shop in the KYSON line of machines.

RMT’s popular KYSON TX5 laser is an excellent example of the power and versatility that RMT offers the tube-cutting marketplace. This 3-kW machine is upgradable to 4 kW and can cut tubes up to 22′ long (21.4′ when fully automated). It has a material processing capacity of up to 5.9″ wide elliptical and polygonal tube, 5.9″ x 5.9″ angle iron, 7.875″ x 7.875″ square tube and 10″ diameter round tube. It can cut tube and profile walls up to 0.394″ (10 mm) thick, depending on material and laser power. This 5-axis machine features an IPG Photonics laser that provides an ultrahigh output power with exceptional beam quality and a higher electro-optical conversion efficiency (25-30%) and lower maintenance costs than many other lasers on the market. The TX5 also sports a fully automatic loading and unloading system.

Whatever your tube or flat laser cutting needs, Revolution Machine Tools can provide the ideal solution for your current projects with an eye to potential future requirements. With their experienced team of machinery consultants, as well as their in-house service and parts departments, RMT is always prepared to give their customers the best possible experience in fabrication machine acquisition, maintenance, and supplies. Please give them a call today for a very competitive quote on your ideal tube cutting fiber laser.