A Roll for Every Shop

Revolution Machine Tools built their reputation early on by offering top-of-the-line hydraulic CNC press brakes in an expansive variety of styles for extremely reasonable prices. As the years have progressed, RMT has become known for quality metalworking machines across most fabrication lines. The best-kept non-secret of RMT, however, is that they have been selling high-end plate rolls along with their brakes since the day they opened their doors for business.

The noble press brake always seems to be the darling of the metal fab shop, a benchmark to demonstrate how prestigious a metalworking business has become. More articles in industry periodicals and words on fabrication-related websites are dedicated to press brakes than plate rolls by a long shot. Maybe it’s because press brakes can be used in a wider variety of shops, while rolls are a bit more specialized. Or perhaps its because a single brake is more versatile in handling a greater assortment of projects than a set of rolls, which is limited by different factors, such as the diameter of their cylinders.

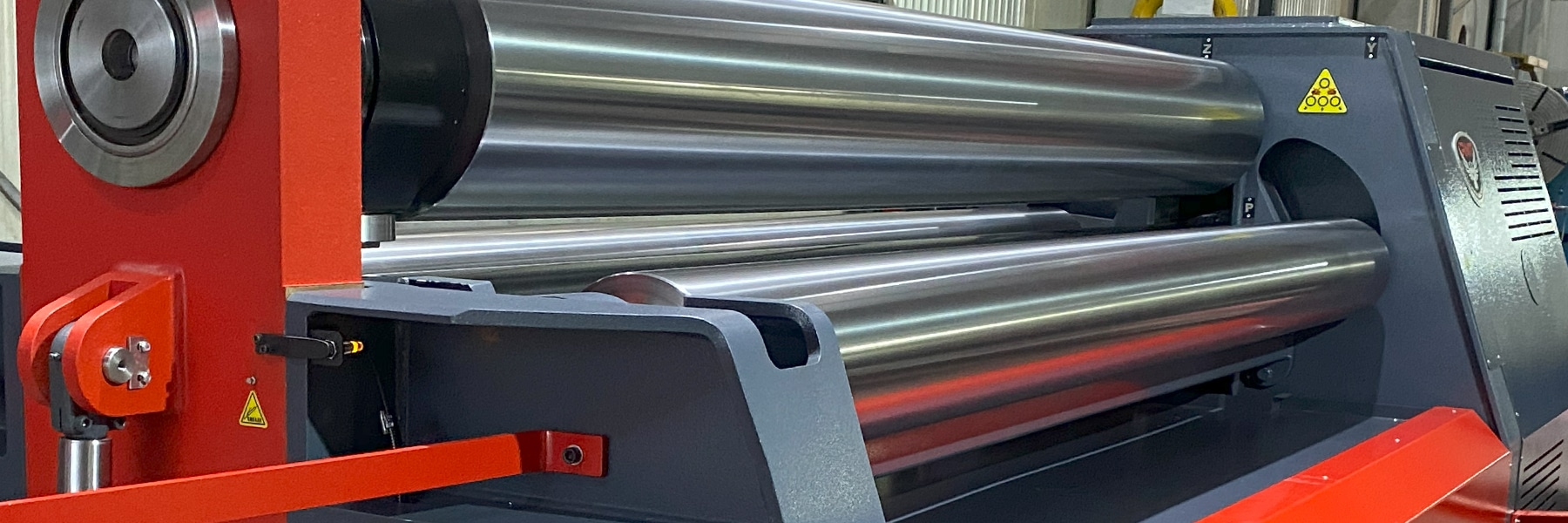

The folks at Revolution Machine Tools certainly wouldn’t argue with those who love their press brakes—after all, their catalog lists over 70 standard models of hydraulic CNC machines spread across five series, plus even larger models available for custom order. However, RMT puts in extra effort to meet the needs of metal rolling enthusiasts everywhere. They offer a staggering 88 models of hydraulic plate rolls, including planetary-type 4-rolls, massive rectilinear-type 3-rolls, and variable geometry rolls. In addition, RMT carries 15 motorized initial pinch three-roll machines, perfect for the light duty sheet-metal shop or HVAC contractors. Never to be outdone by the competition, RMT adds to this impressive inventory 14 models of their own brand of aircraft rolls—a hard-to-find piece of equipment that is designed specifically to form the leading edge of aircraft wings with their changing radii.

Having considered nearly limitless contingencies, the professionals at Revolution Machine Tools have truly created plate rolls for every type of metalworking shop.

How to Buy the Perfect RMT Plate Roll

If you desire to find the ideal plate roll from Revolution Machine Tools for your shop, there is a remarkably simple way to go about it—call and talk to a machinery advisor at RMT. These representatives are not fly-by-night snake oil salesmen, but rather trained consultants who strive for excellence in setting the customer’s needs first and foremost. They know they are building associations—and even friendships—that can last a lifetime and be profitable for all parties concerned.

With their commitment to service, RMT’s machinery consultants will offer a site assessment before even listing possible models to a customer. They will evaluate a shop’s production area to see if RMT’s machines will be a good fit. Among considerations are how the machine will be brought into the building and where it will be positioned. They can verify if adequate electrical and hydraulic requirements will be met, determine if any of the surrounding equipment poses a risk of interference through vibrations or electromagnetic emissions, and even address the best ways of material handling and dealing with scrap removal.

The men and women at Revolution Machine Tools will work to match a plate roll to your current and anticipated applications. They have researched all advantages and disadvantages of every machine they sell and will explain in detail why their recommendations should work best for your situation.

However, if you want to do a little homework on your own before you call, here are some suggestions to help you begin:

- Learn plate rolling fundamentals and roll theory.

- Understand clearly what your result will be with each of your anticipated jobs, including surface finish and any specialized shapes.

- Determine the minimum and maximum diameters of the cylinders you will need, as well as their lengths.

- Evaluate what possible future jobs could arise.

- Study the types of materials you will be rolling and make certain you comprehend the various dimensions and properties of the metal, including tensile strength and yield.

- Investigate the different types of plate rolls there are—including numbers and arrangements of the rolls—and for what jobs each style is used.

- Know why prebending is important and how it works.

- Learn about crowning and its significance.

- Find out about the maintenance needs of plate rolls.

- Estimate what options you might need, such as material supports or parts handling equipment.

- Calculate what your total budget can reach.

- Have trained operators on staff before the purchase and involve them in the decision-making process.

- Visit RMT’s website and look through their current offerings of plate rolls. Study the different series of machines and learn how they work and why. Analyze the various options that are available for each model and determine which might be potentially useful in your operation.

When you’ve completed your education don’t hesitate—call an RMT consultant right away to confirm your observations that a plate roll from Revolution Machine Tools is the best solution for all your metal-rolling needs.