SOFTWARE

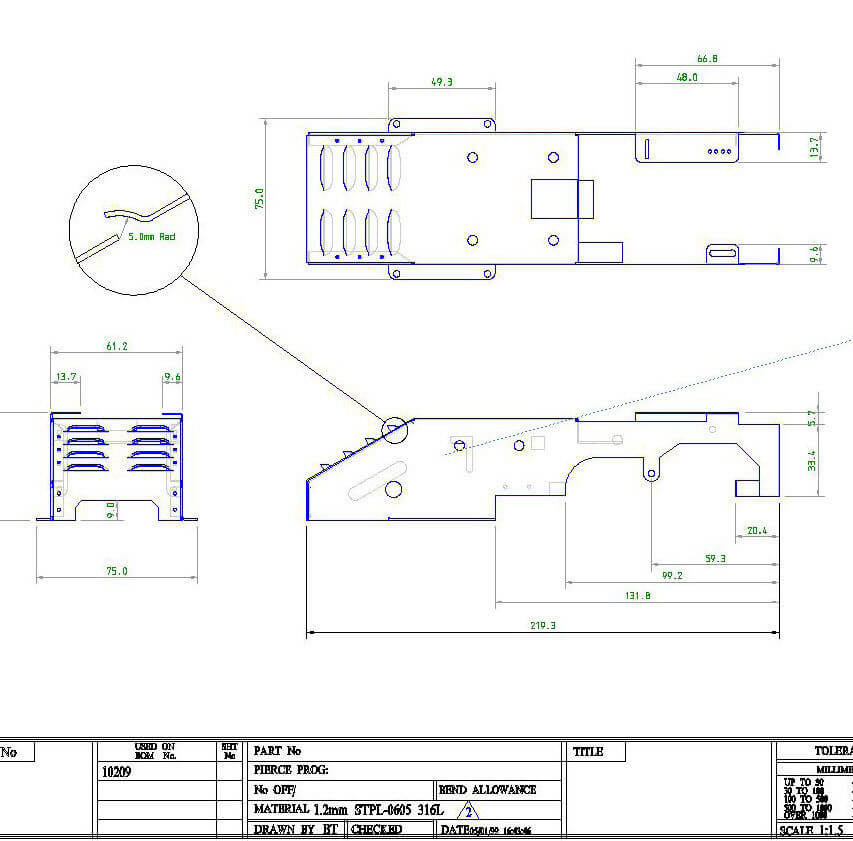

RADRAFT

RADRAFT

Radraft provides users with a comprehensive drafting solution for all your 2D design and drawing needs. Although easy to use Radraft has many advanced features to assist with the quick production of drawings and parts. With its compact GUI (Graphical User Interface) users can access a wealth of drawing tools and parametric profiles.

Features at a glance:

– Fully featured 2D drafting package

– Very quick and easy to use

– Compact yet fully featured graphical user interface

– Supplied with a library of parametric engineering profiles

– Exchange drawings via DWG, DXF and IGES

– Parametric dimensioning

– Parametric expressions

– Automatic profile healing

PRODUCTIVE ENGINEERING DRAWING

Radraft is a highly productive tool that will meet all your engineering drawing needs. The full toolset of drafting functionality is available for all other 2D geometry tasks within Radan.

DRAWING ATTRIBUTES

Radraft drawings come with a host of standard and customisable attributes. These attributes can be used to store and retrieve valuable information about the drawing such as revision, drawn by, material etc.

INTELLIGENT PROFILE SMOOTHING

Radraft’s Geometry Utility can simplify or smooth the geometry profiles. Some file types can’t support complicated splines or arcs and consequently represent these by using many very short straight line segments. Such profiles can be difficult to work with and can cause problems when trying to apply tooling in the manufacturing process.

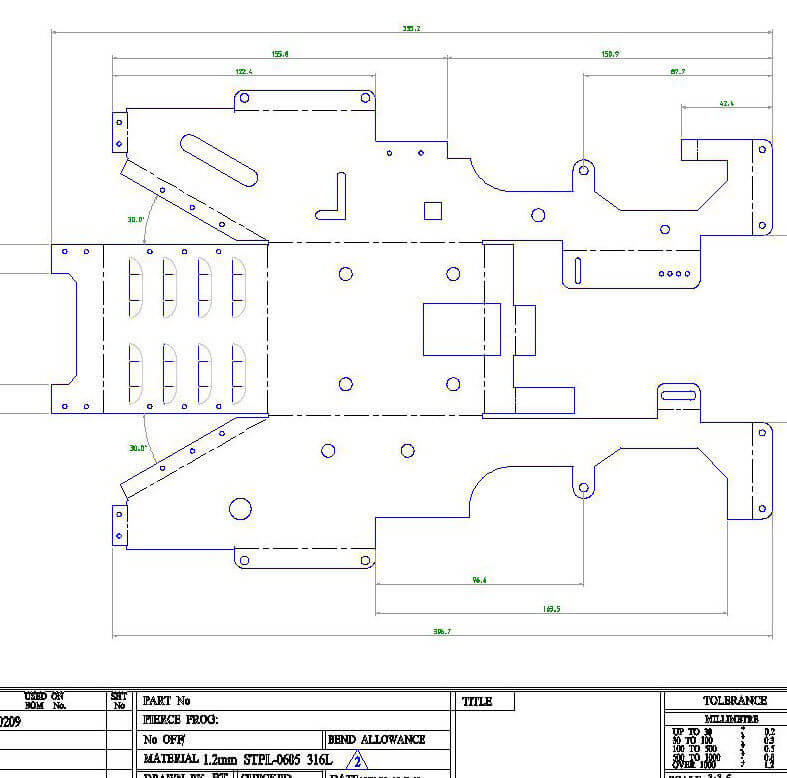

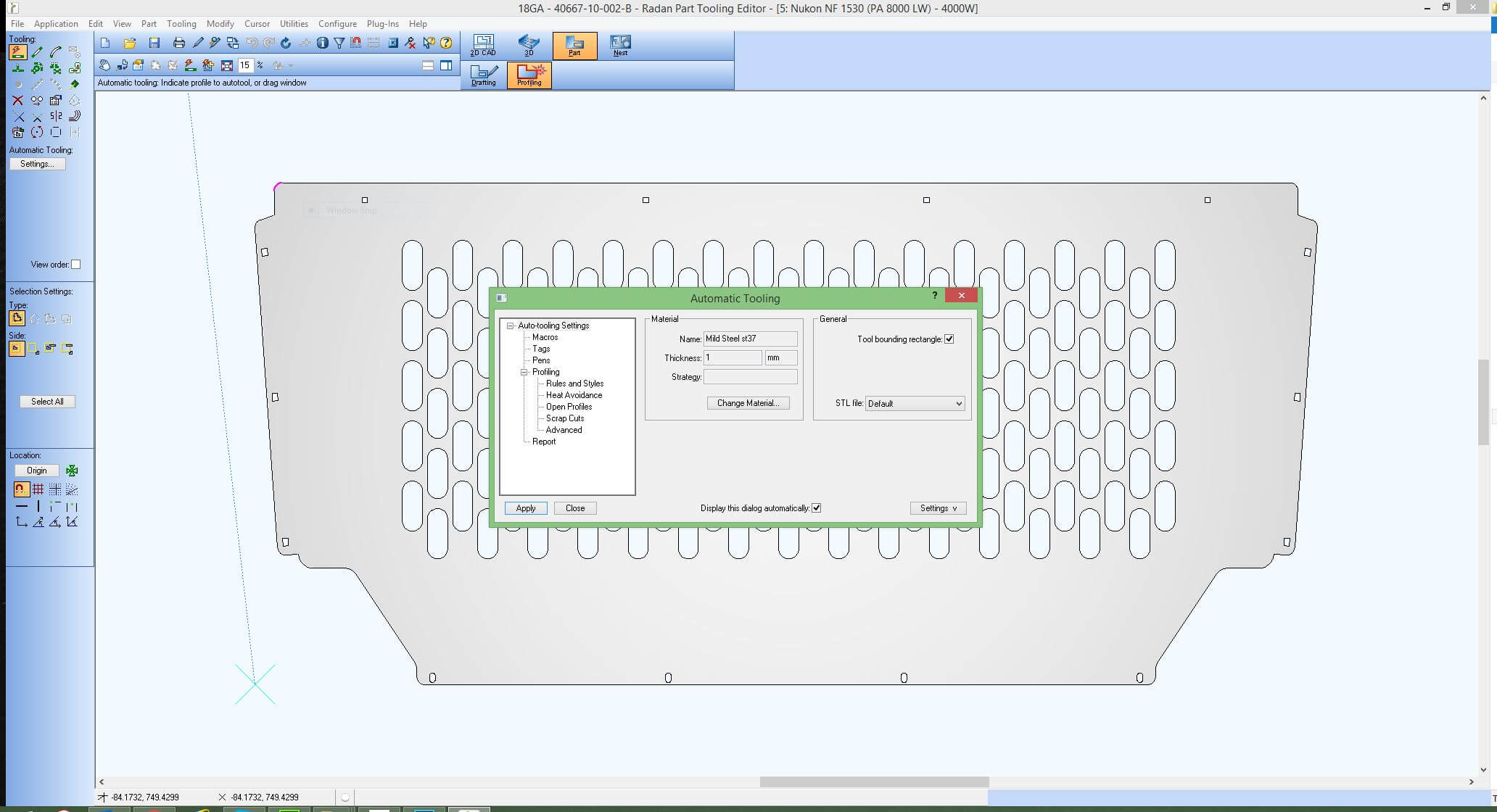

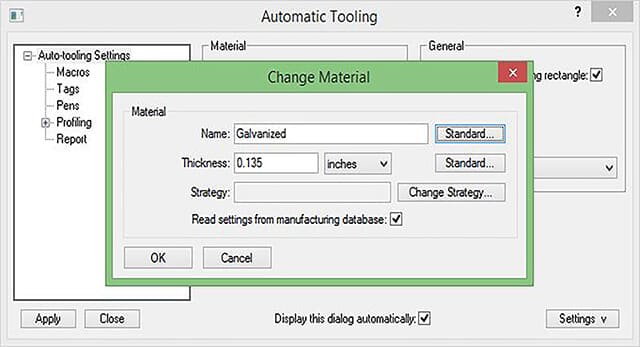

RADPROFILE

RADPROFILE

RMT – KYSON Fiber Laser using software RADAN Radprofile Cad – Cam with its own postprocessor. For ease of cutting has many features like auto nesting and machining, calculating the time, micro-joint, total cut and more. All data for cutting is installed in the technological Radan charts. This program is designed for nesting and machining and is installed directly on the CNC, without any adjustment of the cutting parameters. Radan has some additional features, if it is unable to cut a hole smaller than (0.5mm by the thickness of the material), it will be marked automatically. Radan is a fast, modern programming application designed to assist in transferring data from CAD to NC code.

Features at a glance:

– Drag and drop data input

– Batch processing of DXF/DWG Smart order lead-ins – maximise safety/reduce runtimes

– Automatic hazard avoidance maintaining head safety Intelligent tagging of components and scrap

– Bridge cutting – reduced costs/times

– Automatic common line cutting

– Automatic remnants, sheet scrapping and off-cuts

– Project nesting incorporating user definable reports

– Graphical program verification

– Quick estimates for parts or nests

– Simple intuitive interface with clear simple icons

– Reduced lead times and increased production flexibility

SEAMLESS PROGRAMMING

Optimising the tool path, cutting technologies and cutting sequence for a profiling machine is paramount to the efficient programming of the machine and thus the reduction of the cost to manufacture a part.

PROCESS OPTIMISATION

Optimising the tool path, cutting technologies and cutting sequence for a profiling machine is paramount to the efficient programming of the machine and thus the reduction of the cost to manufacture a part.

POWER AND CONTROL

The power of automation with the ability to control by your preferences. The Radprofile programming solution provides your operators with easy to use software that can be educated to adopt your preferred practices and processes.

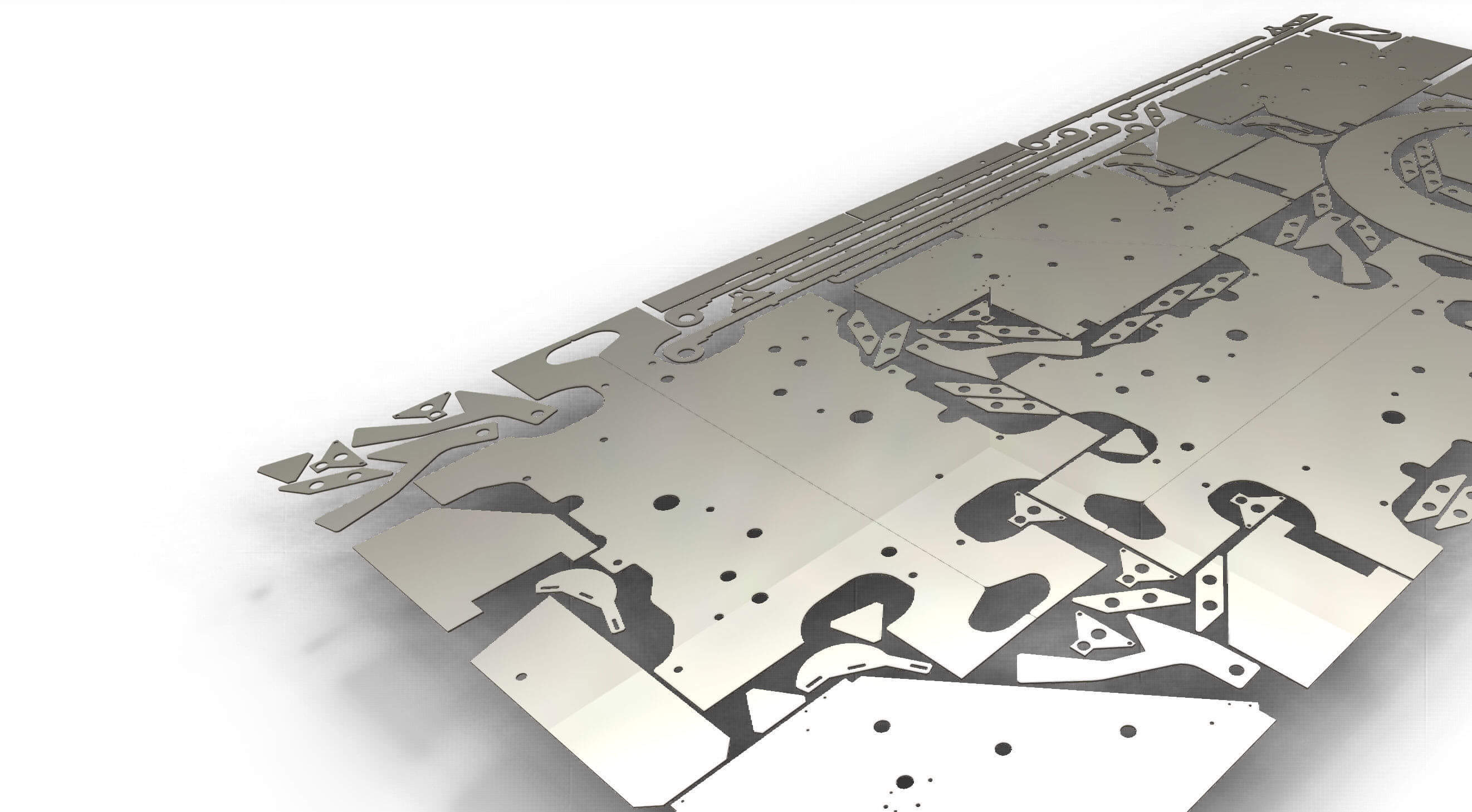

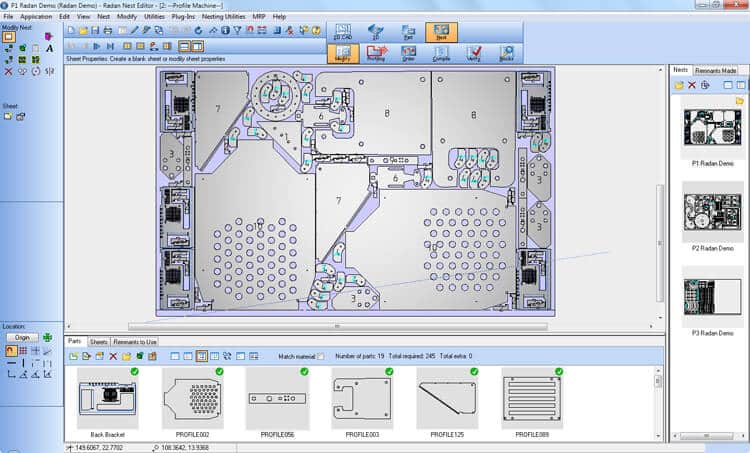

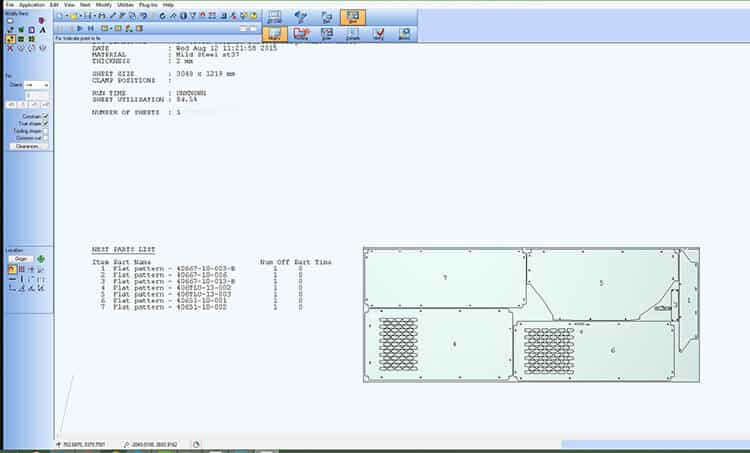

RADNEST

RADNEST

Radnest analyses the true shape, material and thickness of all components in a batch, separating and sorting automatically, producing high utilisation, manufacturable nests from sheets, off-cuts and remnants delivering substantial savings in material and improving machine efficiency.

Features at a glance:

– AIncreased material utilisation with the ability to prioritise sheets

– Improved machine efficiency

– Reduced lead times through dynamic nesting and enhanced data imports

– Automatic material sorting

– Automatic remnant usage and tracking

– Easy integration and inclusion into your current work flow

– Flexible and powerful nest editing tools

– Machine specific nests with associated

– CAM rules Simple intuitive interface with clear simple icons showing status

PROFILING WITH RADNEST

When used with Radprofile, Radnest can automatically produce common line cuts between adjacent parts to further increase material utilisation and reduce cycle time, gaps between components are controlled by the kerf width created by a given material, thickness and cutting method for a specific machine, this data is stored within Radan meaning that complete automation is possible.

ADVANCED NESTING FOR PUNCHING MACHINES

When Radnest is used with Radpunch, the tooling for each part is compared against the available stations in the turret or tool changer. This may restrict the orientations at which a part can be placed or mean that a different part is selected for the current nest. It is extremely important that the nest produced does not exceed the tooling capacity of the machine tool, as this would result in a program that could not be run.

EFFICIENCY IS EVERYTHING

Radnest is a fast, modern nesting application designed and written by Radan to get the absolute best from available options whilst still allowing a human touch when required this is crucial in fast moving ever changing production environments.