An Intelligent Approach to Green Bending

Press brakes and electric brakes from Revolution Machine Tools are smart machines. No, they aren’t outfitted with artificial intelligence and are planning a revolt against the humans, but every single press brake RMT makes is CNC-equipped to help take the guesswork out of the bending process.

RMT got its start by wanting to offer high-quality press brakes and plate rolls to the metalworking community, and they’ve since extended their offerings out over the whole spectrum of metal fabrication equipment. Press brakes remain at the heart of RMT, however, and they excel in the market by offering over 50 models of high-end hydraulic CNC Y1/Y2 machines.

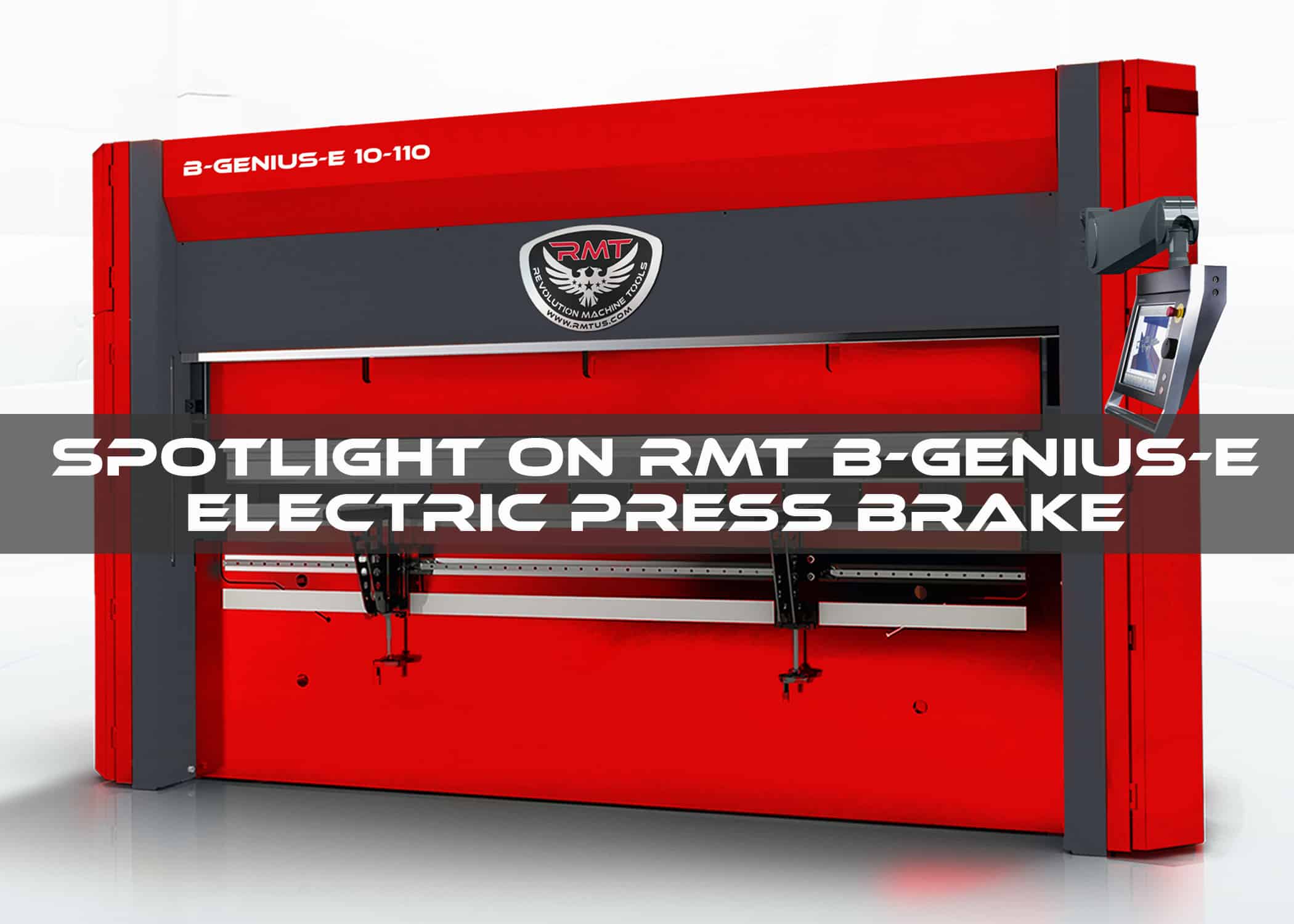

Because every press brake they build is a CNC machine, RMT goes so far as to label their “starter” press brakes as their B-SMART Series, and their more advanced electric brakes with additional axes of control their B-GENIUS Series. Wanting to accommodate fabricators of every stripe, RMT added to their portfolio by introducing four models of electric press brakes in their multi-axis B-GENIUS line, running from 5′ to 10′ in bending length and from 50- to 120-tons in capacity.

Designated as the B-GENIUS-E Series, these cash-saving, environment-friendly marvels use approximately 69% less energy than their hydraulic counterparts and are remarkably quiet during operating cycles. Furthermore, when they are in standby mode, they save a whopping 98% over the energy used by hydraulic brakes.

Besides savings in operational costs, the lack of hydraulic systems in RMT electric brakes means savings in other areas as well: no purchasing—or disposal—of costly hydraulic oil, no repair or replacement of hydraulic components, and no hydraulic system consumables to worry about, such as filters and seals. (Plus, no hydraulic oil leakage soiling the shop floor.)

Like all press brakes from Revolution Machine Tools, the precision machines in the B-GENIUS-E series feature what RMT calls “the large trio of value,” namely, a larger than normal open height, a larger stroke, and a large throat depth.

B-GENIUS-E Series Electric Press Brakes Available from RMT

- 50-ton RMT B-GENIUS-E 5-50 | 5′ 2″ total bending length (6′ between housings) | 23.2″ daylight | 12″ stroke | 3 hp motor

- 80-ton RMT B-GENIUS-E 7-80 | 6′ 10″ total bending length (7′ 9″ between housings) | 23.2″ daylight | 12″ stroke | 3 hp motor

- 100-ton RMT B-GENIUS-E 9-100 | 8′ 6″ total bending length (9′ 5″ between housings) | 23.2″ daylight | 12″ stroke | 3 hp motor

- 120-ton RMT B-GENIUS 10-120 | 10′ total bending length (11′ 6″ between housings) | 23.2″ daylight | 12″ stroke | 3 hp motor

Each B-GENIUS-E electric brakes comes equipped with a 6-axis CNC with Y1/Y2 precision ram positioning, an X/R precision servo-driven back gauge, and Z1/Z2 axes. They are available for ordering with more than a dozen additional axes of control, including X1/X2, R1/R2, X Prime axis (Delta X) with +/- 5″ stroke (10″ total), X axis with 40″ external travel (includes back protection with light barrier), X1/X2 axes for light pole production, sheet follower with a sliding guide (motorized height adjustment), front feeding system with supports, and front feeding system with supports and pneumatic pushers.

The standard control unit is a user-friendly DA-66T touch screen CNC control unit featuring 3D graphical visualization from Delem, the leading manufacturer of CNC press brake control systems in the world. For those who want even greater performance, the control can be upgraded to a Delem DA-69T touch screen 2D/3D CNC. For those who prefer it, a Cybelec ModEva 10S/12S/15S 3D control with PC 1200 3D SW can also be substituted.

For quick and easy tool replacement, these brakes are provided with American/European section-style box punch clamps but can have American-only style punch clamping substituted. Available optional clamping systems include quick release clamping, as well as brand-name hydraulic or mechanical clamping from RMT, Wila, or Wilson. Various tooling options and packages are available, including RMT, Euro-American, Wila, or Wilson.

Safety is a priority at RMT, and all four electric brakes sport a a manual F. AKAS II M -FPSC-B-C safety laser (upgradeable to a motorized F. AKAS III M) including safety covers and switch. Other protective covers—side and rear safety doors—are included to prevent injuries during operations, and a rear work light keeps things illuminated behind the scenes. An optional SICK C 4000 light curtain can be added for machines that are run in tandem, trio, or quad configurations.

Your Personal Press Brake Consultant

Regardless of your metal-bending needs, please call and talk to a sales consultant from Revolution Machine Tools today and discuss your upcoming projects. With their outstanding lineup of hydraulic and electric press brakes—not to mention hybrid machines for those who prefer the best of both worlds—RMT has the perfect solution for whatever fabrication job comes your way.

RMT machinery consultants take their customers—and their customers’ projects—very seriously and perform onsite assessments of their production areas to make sure any recommended machines will work properly in their operations. They back up every sale with in-house service work, replacement parts supplies, tooling sales, and other amenities. As RMT founder and president Kyle Jorgenson has said, “At Revolution Machine Tools, it is our passion to help others succeed. We believe that manufacturing is the backbone of our economy and that by providing the best solutions to make our customers successful is how we measure our own success.”