The Angle on Plate Beveling

The noun bevel means an angle that is cut into the edge of a structure like a steel plate that isn’t at 90° to the plate face. The verb bevel means to create such an angle by cutting or grinding. It should be noted that in US usage, the terms “beveled” and “beveling” only have one “L” and the original UK spellings use two, so both spellings will be found in metalworking books and websites.

Some other important terms related to angle cutting are:

- Chamfer. A term that is often used interchangeably with bevel, chamfer refers to an angled transition between two faces of an object. Usually, the faces are at 90° to each other—like the surface and the edge of a plate—and the chamfer is just a cutaway corner that still leaves the furthest section of the edge intact at 90°. While a bevel may leave some of the edge at a right angle, it often extends all the way from the top to the bottom of the workpiece at an angle, coming to a sharp point. Chamfers are also usually 45° cuts, where bevels can be made at any angle.

- Miter. A miter is an angled cut made across the face of a workpiece. In the case of a metal plate, it would be angled between the length and width of the plate, but still be a 90° cut in the edge (or depth) of the plate. A metal-cutting saw might have both a miter and a bevel feature—and they both may be employed at the same time—but they refer to two different kinds of cuts. Mitering involves rotating the workpiece or the blade away from a 90° angle horizontally, while beveling involves tilting the blade away from a 90° vertical angle in reference to the workpiece and the table or vice that secures it.

Beveling is performed on metal objects for several reasons, such as making the workpiece safer by removing a sharp corner, or for the final part to be more visually appealing. The most common purpose of beveling a piece of metal plate, however, is to help prepare it to be welded.

In butt welding, where the edges of two pieces of metal are butted up against each other in the same plane to be welded, only a small gap will remain between them for the welding metal to penetrate. Beveling creates a groove where the two edges come together, increasing the surface area of the weld site so it can hold more of the welding metal, in turn making the piece more secure and stress resistant. This is even more important if the surface of the combined pieces will be ground and finished, removing the external welding metal that would otherwise help fasten the sections.

While beveling plate edges has long been performed by hand using grinding wheels or flame cutting equipment, the advent of specific beveling machines—usually just called “bevelers”—revolutionized the plate fabrication industry by turning a process that could take hours into one that can be measured in minutes or even seconds.

Advantages of RMT Plate Bevelers

Plate bevelers from Revolution Machine Tools take that technological revolution a step further with RMT’s dedication to employing cutting edge design and state-of-the-art components in all the equipment they offer, along with their exemplary record of going above and beyond the norm in their approach to continuous customer service.

In their insistence on excellence, RMT exclusively employs milling-type cutting tools in their plate beveling machines, eliminating most of the headaches associated with weld preparation that utilizes grinding or torch welding. The benefits of RMT’s PBV-FAB series of bevelers include:

- Uniform beveling with strong, clean edges

- No HAZ (heat affected zones) or warping

- Faster, quieter, and safer operation

- Less dust, for a cleaner work area

- Lower labor costs

In addition, RMT bevelers can accommodate a variety of sizes up to their maximum capacities, and the upper models feature adjustable bevel angles to satisfy the most exacting fabricators. RMT’s plate bevelers are chosen time and again for their ability to produce the perfect support for any weld.

Plate Bevelers Available from RMT

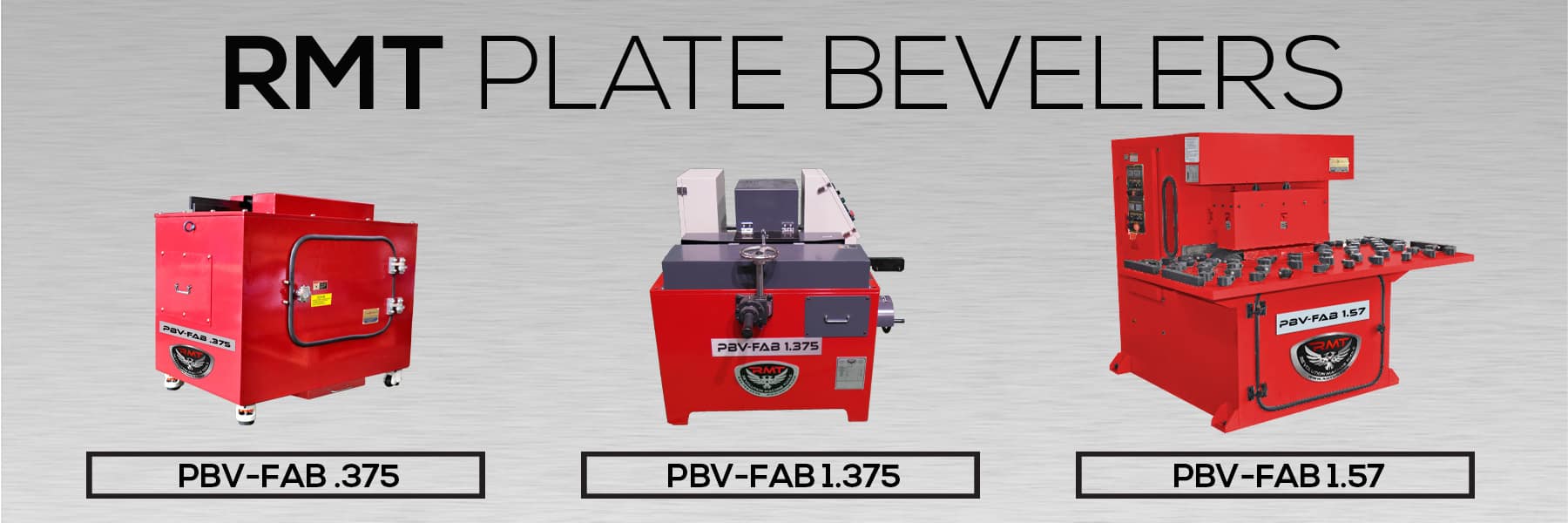

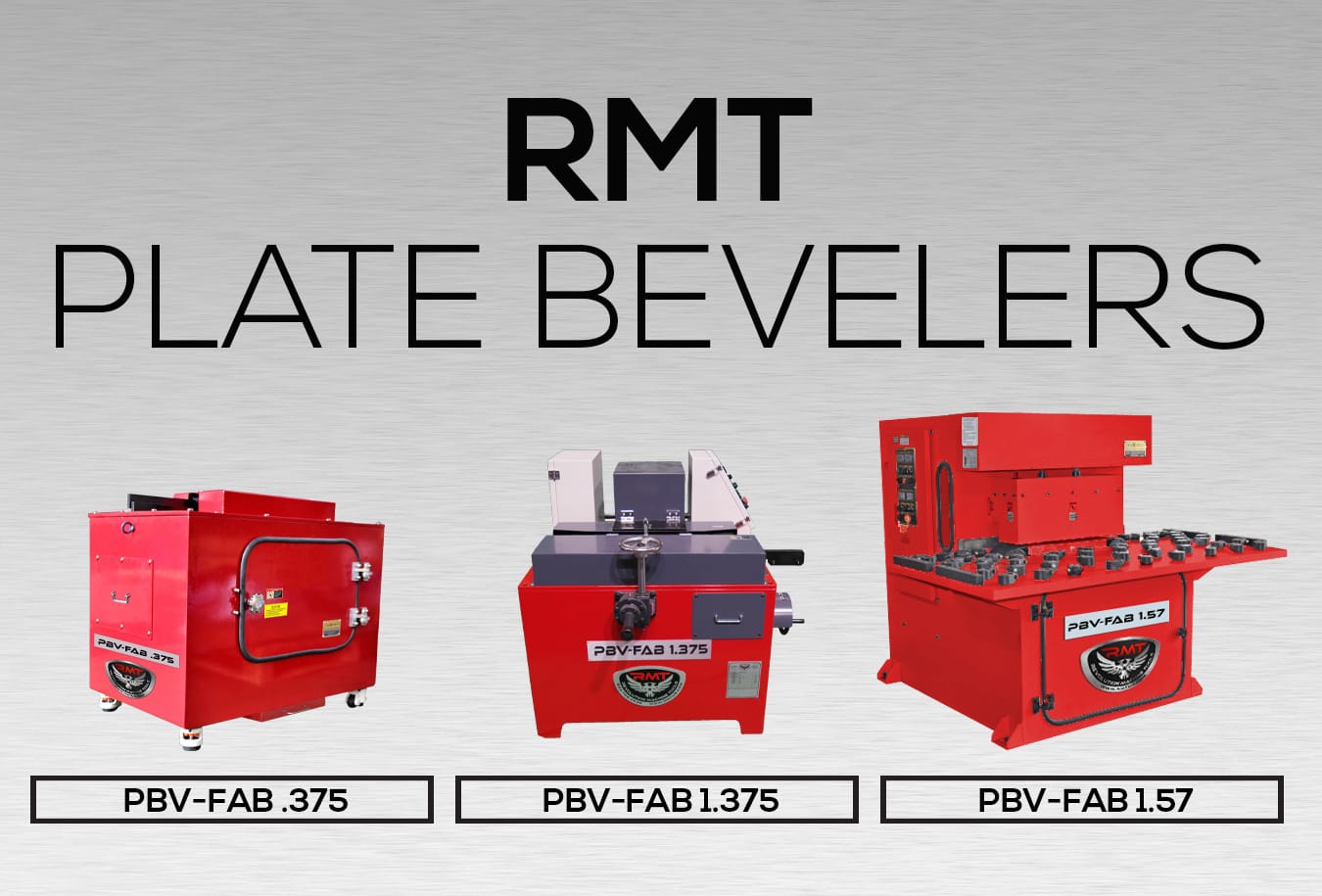

Revolution Machine Tools currently offers a series of three different plate bevelers to match the varying needs of fabricators small and large:

- PBV-FAB .375 | The “baby” of the group is no lightweight, able to process 3/8″ plate and weighing in at over 800 pounds. This semi-automatic rotary cutting tool equipped machine can process any material that can be milled. Widely used in educational institutions, it is safer than a milling machine (not to mention ten times faster). It can bevel plates from 4″ long up to any length that can be supported by the handling equipment in the shop. The beveling angle is fixed at 32° for the standard machine, but a different angle can be optionally ordered.

- PBV-FAB 1.375 | With a beveling speed of up to 48″ per minute, the middle model in RMT’s lineup easily bevels plate up to 1-3/8″ thick. Both the feed speed and the milling head RPM are infinitely variable, and the machine offers a wide range of thickness and depth capacities. It has an adjustable beveling angle of 15° to 55°. Any length of plate from 4″ up can be processed, depending on the customer’s support system.

- PBV-FAB 1.57 | The biggest entry in the roster is a heavy-duty semi-automatic machine that can bevel plate from 0.12″ to 1.58″ in thickness and from 10″ in length on up. With its power degree control, it can be easily set to bevel any angle from 15° to 45° and the workpieces are loaded horizontally, for better handling of larger plates. While it weighs a touch over 3600 pounds, the machine has a petite footprint, barely taking up more than 5′ in either width or depth when not loaded with a workpiece.

The Name You Trust

Revolution Machine Tools has earned a reputation in the metal fabrication industry as a supplier of top-of-the-line plate processing equipment, from their massive selection of over 70 models of RMT press brakes, to their powerful 4-roll and variable geometry plate rolls. Now they’ve expanded their offerings with tools to assist in the welding of flat and rolled plate with their plate bevelers and pipe rotators.

Whatever your fabrication needs, please call RMT for a facility evaluation and a competitive quote on your next ideal metalworking machine.