The Coming of the Fiber Laser

Just as using a plasma cutter on a plate of metal was a big step beyond the traditional cutting methods of using a punch or router, likewise, processing plates with lasers—first CO2 and eventually fiber (tube cutting fiber lasers)—was a quantum leap for fabricators. Laser beams are streams of highly amplified photons that travel in the same direction and at the same frequency. Since this special type of light doesn’t “scatter” like the light from a bulb—or the sun—it is still in a very narrow line when it strikes a surface, creating much greater brightness and heat at the point of impact than normal light. This allows a low-power laser to be used as an instructional pointer, while a high-power laser can be used to cut through hard metals and other materials quickly.

Early on, carbon dioxide was found to be a good medium for scientists to use in the amplification of energy needed for lasers to operate. Atoms in this “gain medium” are stimulated by the introduction of electricity and shed photons as their electrons transitioned to a lower energy state. CO2 lasers use mirrors to bounce the photons back and forth through the gain medium, generating even more photons from the atoms they encounter. This amplified emission of photons of the same phase creates the coherent light of the laser beam.

Fiber lasers were developed when scientists discovered they could replace gas and other substances with a spool of optical fiber that had been specially implanted with rare earth elements to serve as the gain medium. Photons generated by diodes excite these impurities in the fiber, creating more photons, which are amplified as they resonate between Bragg gratings at either end of the fiber. This solid-state design eliminates the misalignment problems that CO2 lasers have with their mirrors.

Why Not Go 3D?

As innovators were finding uses for lasers in a wide variety of industrial settings, metal fabricators were looking for other ways that this technology could be adapted in metalworking beyond cutting flat metal plates in two dimensions. Since working with three dimensional long pieces like angle iron and metal tubes is commonplace in fabrication, concepts were developed for applying lasers in processing profiles. Other than solid round and square bars, most profiles are hollow with relatively thin surfaces, no thicker than a heavy metal plate. If an average power fiber laser could cut a plate of a certain thickness, then it stood to reason that it could also cut the surface of a profile of a similar thickness.

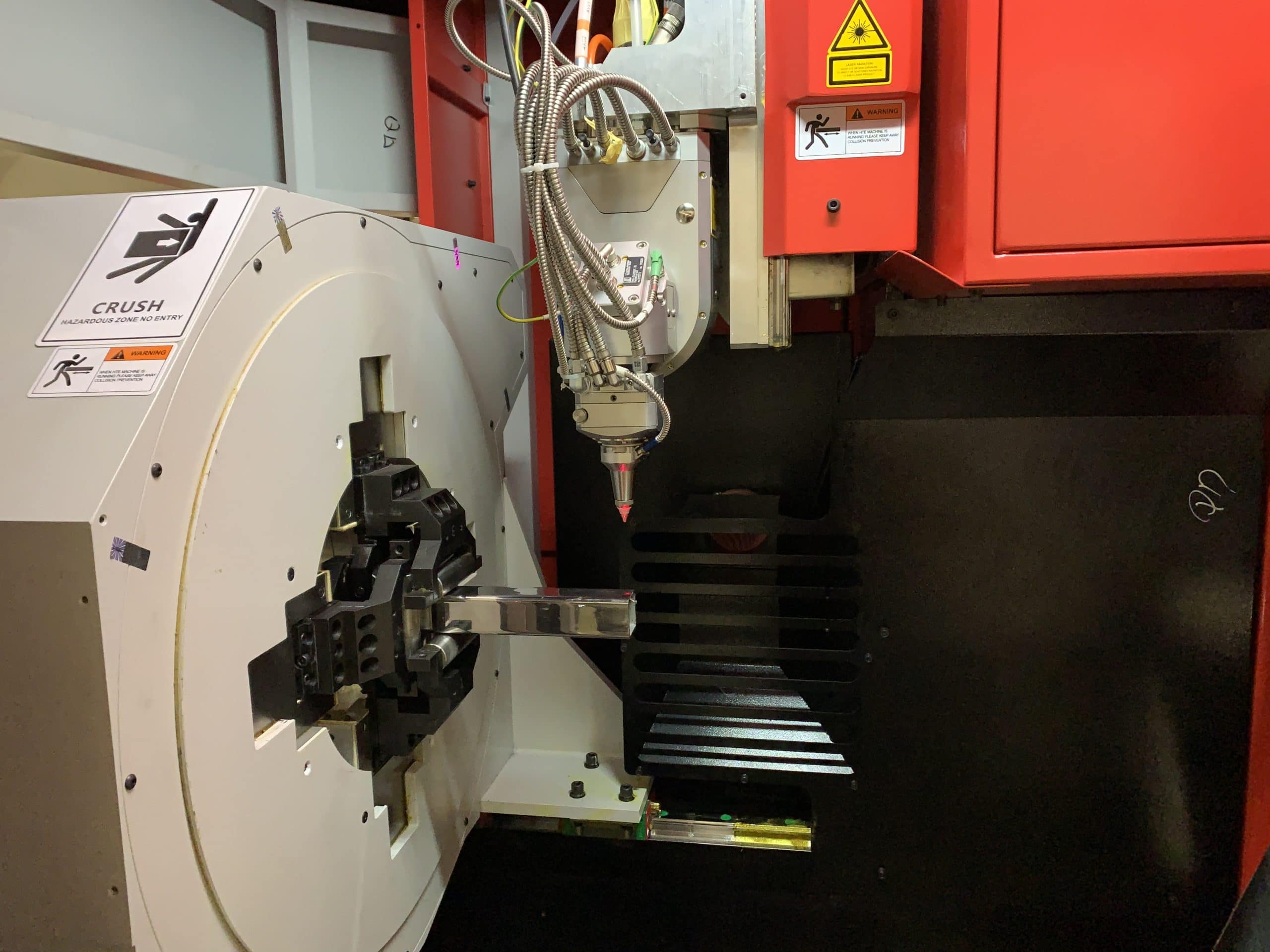

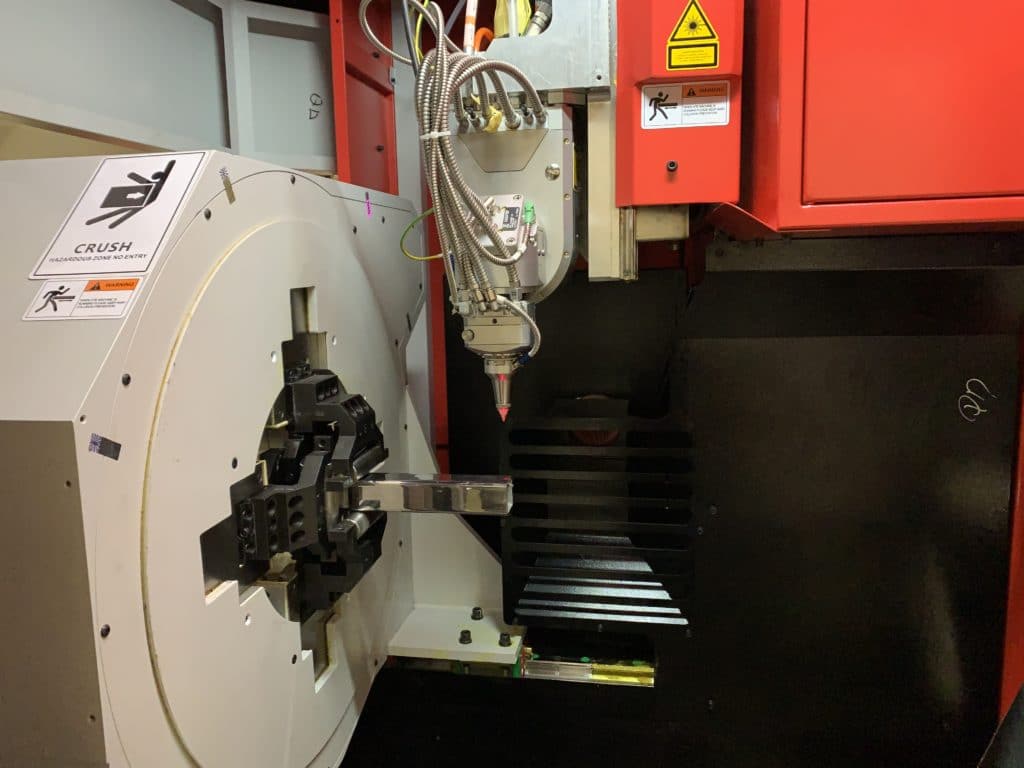

Delivering the laser head to the material was the challenge, and it was solved by turning the problem around and moving the material to the laser head. Since profiles share the characteristic of being long and thin, it was just a matter of creating the means to move the workpiece along its long axis, while rotating it as needed so that the surface to be cut faced a relatively stationary cutting head. Cutting would still take place in basically two axes with the head moving back and forth laterally across the narrow dimension of the surface (Y-axis), while the machine would advance and withdraw the profile along the long feeding dimension (X-axis) while cutting. When cutting was completed on one face, the workpiece could be rotated to the next side—or continuously rotated (A-axis), in the case of round tube. Some machines have added additional axes, such as moving the head vertically while cutting (Z-axis) or pivoting the head up to 45° for a true diagonal cut.

Advantages of Tube Cutting Fiber Lasers

Compared to traditional means of shaping profiles such as shearing, sawing, punching, drilling, or milling, tube cutting fiber lasers offer many advantages for the busy fabricator:

- They have extremely high cutting precision, not only providing accurate parts, but also clean cuts with a flat kerf and little to no burr that needs to be removed in a secondary operation.

- They are a non-contact form of processing that causes only minimal deformation in the cut part due to the very small zone that is affected by the laser’s heat.

- They are very flexible, being able to process many different metals and other materials, as well as different lengths, diameters, wall thicknesses, and profile shapes. Fiber lasers also have an advantage over CO2 lasers in that they can cut highly reflective materials.

- They are extremely efficient, making them ideal for mass production where workflow is a serious consideration. Along with eliminating secondary processes like deburring, there is no excess material left behind that needs removal. In a single operation, the blank can be cut to length and then etched with intricate designs. Tube cutting lasers can also be equipped to load parts automatically.

- They are ideal for processing parts that must be welded because of their clean cuts, and they can make precise incisions that can allow a tube to be manually bent before welding, if needed.

The Bottom Line

The efficiency, flexibility, and precision of tube cutting fiber lasers make them the fabricator’s choice for producing parts from profiles, whether simple or complex. The initial cost of the machine will be absorbed quickly and repaid many times over for the metalworking shop willing to invest in a fiber laser for tube and profile cutting.