When You Need to Build an Airplane

Not long ago the owner of a fabrication company needed to make some intricate curves in metal that altered their geometry along the length of the workpiece. Realizing that it resembled the varying contours found in an aircraft wing, he learned that a machine known as an aircraft roll could form such a complex shape. The only problem was that the inventor and producer of such rolls—the Farnham Manufacturing Company—had decades earlier shuttered their facilities, along with most of the copycat businesses that had briefly popped up. The man was advised that to solve his dilemma he needed to find someone selling used Farnham rolls, which he discovered was not an easy task since there was a high demand in the market for old Farnham machines.

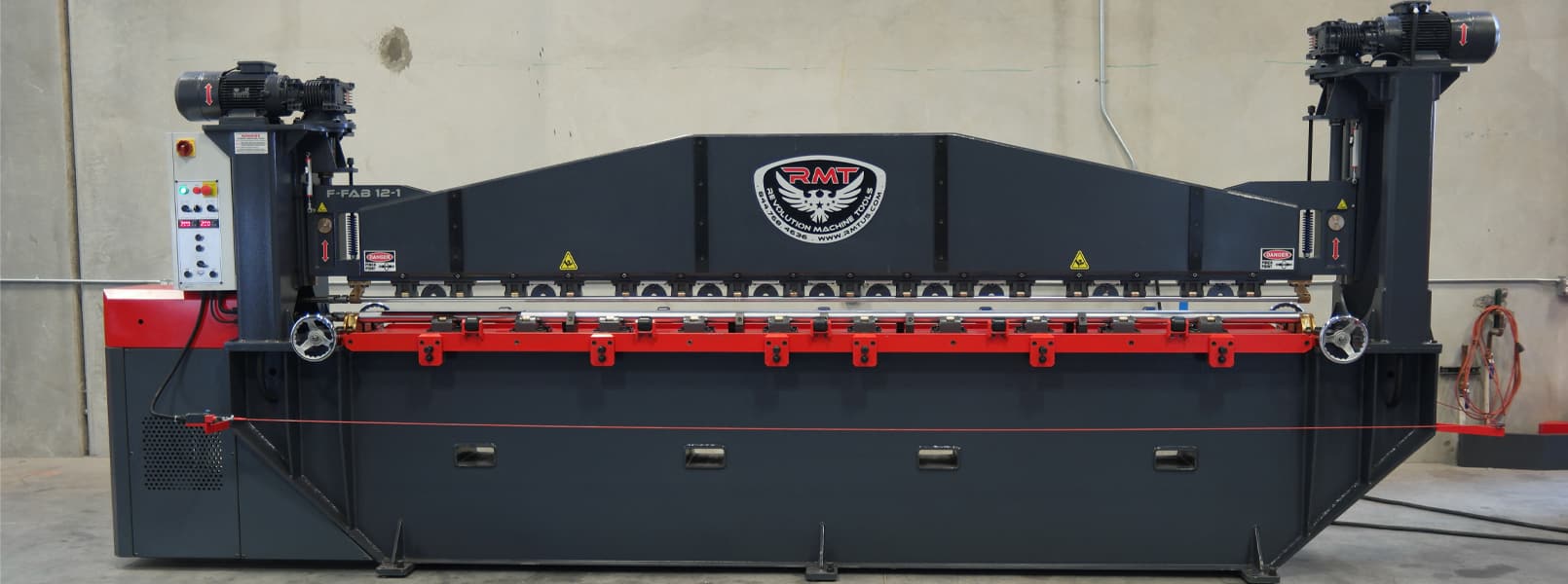

Locating an archived listing on the Internet, he contacted a used machine tool dealer in the Western U.S. who had previously stocked a couple of old Farnham rolls. The dealer told him that while both rolls were now gone, he might be able to provide him with a solution and took down all the necessary specifications. This dealer had done business with Revolution Machine Tools in the past and knew they were building modern aircraft rolls to fulfill this very need. An arrangement was made to broker a machine to the exact specs requested and the customer wound up the owner of a brand-new RMT aircraft roll that featured state-of-the-art technology and cutting-edge craftsmanship that the people back at the old Farnham company never could have imagined.

Revolution Machine Tools was founded with the philosophy that the technologies of the past are ineffective in keeping pace with the challenges that arise in the metal fabrication field, therefore better tools are constantly needed to properly equip fabricators to be competitive. As with their innovations in press brakes, plate rolls and other metalworking machines, the team at RMT saw the need for manufacturers of aircraft and others to have the ability to easily form complex contours in metal and they engineered a solution.

Noting that the historic aircraft rolls were no longer being built, RMT President Kyle Jorgenson said in a promotional video, “We decided to bring them back. We have some customers that need them. It’s really hard to find used machines—especially in good condition—with the capabilities of this machine.”

Benefits of RMT F-Series Aircraft Rolls

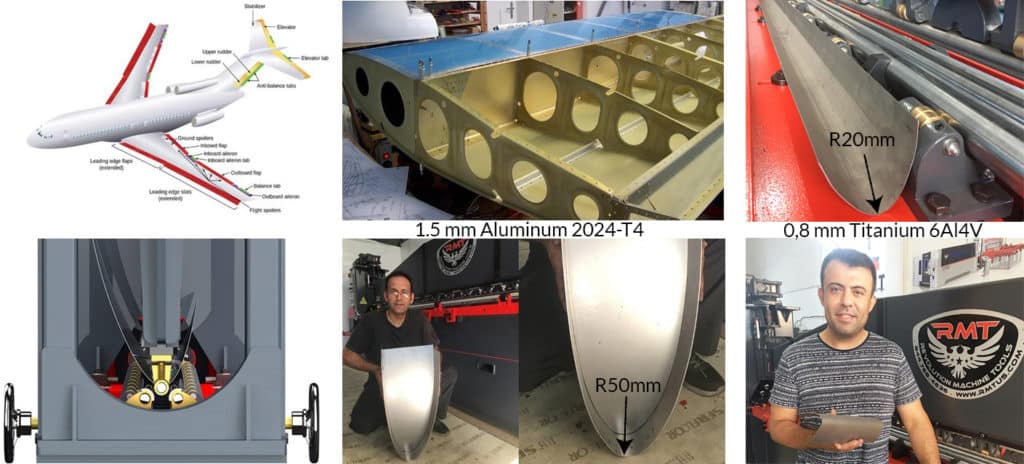

Unlike the flat wings of your childhood’s paper airplanes, the leading edges of an aircraft’s wings are a bit more complicated. Instead of holding a constant shape from their tips to where they join the fuselage, airplane wings taper, altering in thickness and angle from one point to the next to provide lift while flying. Aircraft rolls like RMT’s F-FAB and F-SMART Series are designed to alter the geometry between the individual rolls in the middle of a rolling process, contouring sheet metal into intricate configurations, making them perfect for shaping an aircraft wing or fuselage panel, something no other machine can easily replicate (and they do it without the need of additional tooling).

Designed and engineered by RMT for high performance, the F-Series aircraft rolls are faster, more precise, and easier to operate than any other comparable rolls on the market. These dual speed rolls feature independent drives on both sides of the upper ram that supports the top roll and include digital readouts that show the position of each side to determine the exact radius that will be produced in the finished part.

The forming rolls on the RMT machines are:

- Made from AISI 1050 carbon steel.

- Induction hardened to HRC 54-58.

- Precision ground and chrome coated to produce parts with a mar-free finish.

- All independently driven by AC motors and helical gear boxes with cardan joints.

- Seated in hard bronze roller bushings.

The robust construction features of RMT aircraft rolls include:

- High quality components for increased endurance.

- A stress-relieved high yield steel frame and upper beam.

- Generous upper beam daylight to allow easy workpiece removal.

- A gearbox disc braking system to prevent the workpiece from sliding.

- World standard electrical components that are easily replaceable off-the-shelf.

Safety features of the RMT rolls include:

- Electrical protection against overloads.

- Mechanical protection against overloads.

- An emergency stop cable running around the machine.

- Safety covers.

While readily able to roll mild steel and aluminum sheet metal, these powerful three-roll machines are designed specifically to overcome the ultra-high yield point of material like titanium-alloyed sheets. This is accomplished due to the very small upper roll which allows a tight enough diameter to be formed to counter the intense spring back of titanium. Deflection is compensated by the fully supported rolls along the full length of the machine, both the independently adjustable bottom rolls as well as the top roll, which is magnetically secured in place across the beam.

RMT Aircraft Rolls for Every Need

The F-FAB Series is RMT’s “basic” line of aircraft rolls, but there is nothing simplistic about them. With lengths ranging from a modest 6′ to a whopping 20’—and larger custom machines can be built—F-FAB rolls include models that can roll up to 10-gauge titanium and 1/4″ in some types of aluminum.

The F-SMART Series machines take things up a notch with a numerical control for very precise repeatability and a portable NC unit that moves with the operator for monitoring the forming process from any angle, making them ideal for fabrication in the aerospace industry.

Honoring the legacy of the Farnham rolls that came before them, the F-Series rolls from RMT can literally give a fabrication company its wings.