The Hottest Line in Cold Saws

Cold saws get their name because the design of their blades allows heat to dissipate, unlike chop saws that generate a tremendous amount of heat as they wear away at a metal workpiece. Cold saw blades transfer the heat of the cutting process to the expelled chips, keeping the blade and the material cool. Even with the constant popularity of bandsaws in metalworking shops, many fabricators prefer cold saws, and their design makes them ideal for specific types of projects.

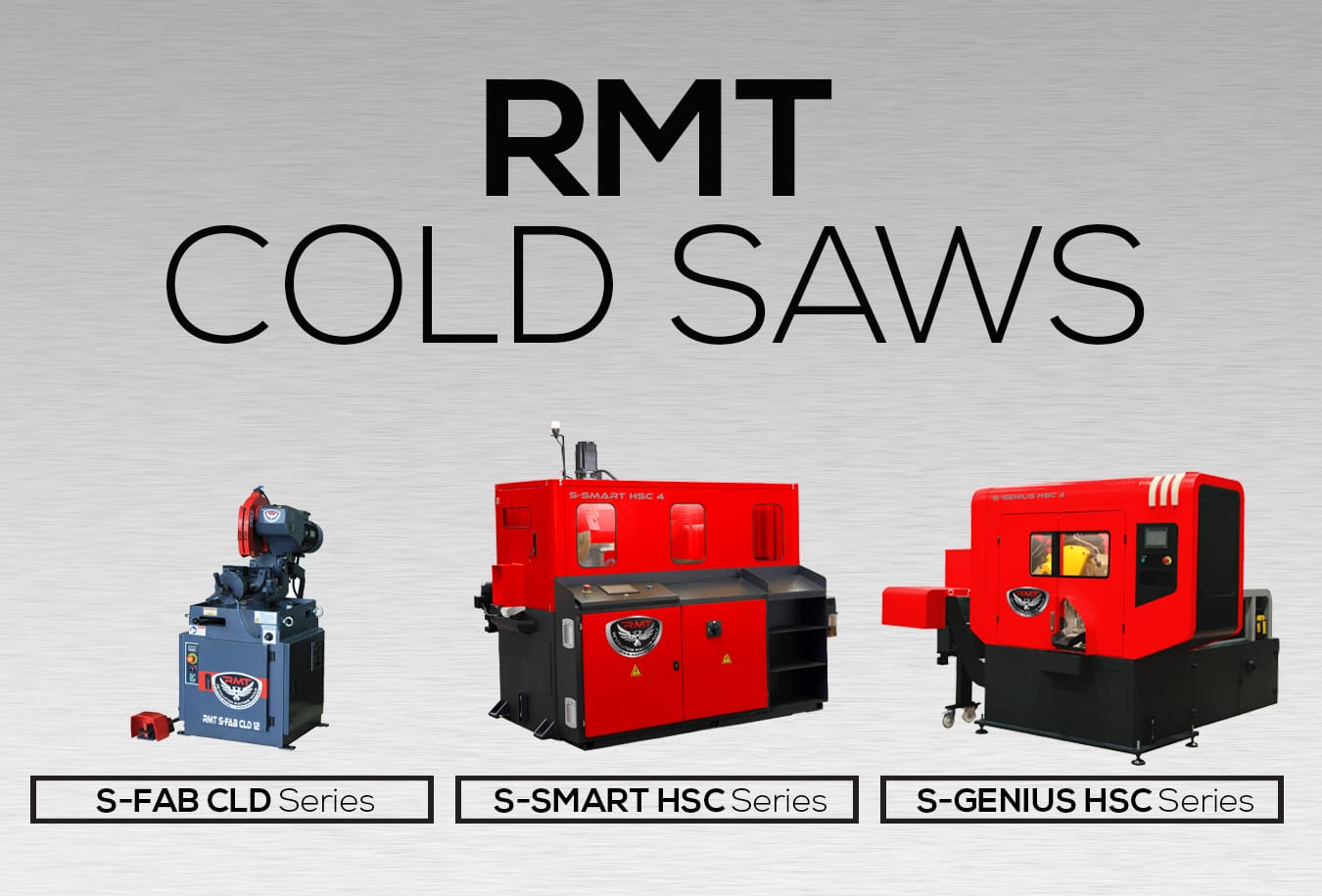

Revolution Machine Tools offers a wide variety of metal-cutting saws for every shop’s needs, currently including over 30 models of bandsaws and eight cold saws. Like most of their machine lines, RMT’s cold saws fall into different series based on their features:

- The S-FAB CLD Series of semi-automatic heavy duty circular cold saws offer high production rates and are ideal for short batch runs.

- The S-SMART HSC Series of automatic servo feed cold saws are designed for mass production in continuous operation. They come standard with a servo feeding vice system and can be outfitted with an optional 20′ automatic material handling table.

- The S-GENIUS HSC Series of automatic servo feed cold saws are designed for continual operation in large scale production. They come standard with a 31″ index stroke servo feeding vice system and a 20′ automatic material handling table.

Current cold saw models available from RMT include:

- S-FAB CLD 10 with a 10″ blade and a round cutting capacity of 4″ @ 90° (2.75″ @ 45°)

- S-FAB CLD 12 with a 12″ blade and a round cutting capacity of 4″ @ 90° (3.5″ @ 45°)

- S-FAB CLD 14 with a 14″ blade and a round cutting capacity of 4.5″ @ 90° (4.3″ @ 45°)

- S-SMART HSC 3 with a round cutting capacity of 0.8″ – 3″ @ 90°

- S-SMART HSC 4 with a round cutting of 0.8″ – 4″ @ 90°

- S-GENIUS HSC 4 with a round cutting of 0.8″ – 4″ @ 90°

- S-GENIUS HSC 4.75 with a round cutting of 1.5″ – 5″ @ 90°

- S-GENIUS HSC 6 with a round cutting capacity of 1.8″ – 6″ @ 90°

Benefits of Cold Saws

RMT cold saws provide certain advantages over other types of metal saws, including:

- Quicker setup. RMT cold saws can be put into operation virtually upon delivery, unlike bandsaws that require time-consuming alignment and testing.

- Cooler cutting. A hot-cutting chop saw will run at around 4000 RPM, but RMT’s highly efficient cold saws run much slower—the variable speed S-FAB CLD Series saws run at 20 – 80 RPM—yet cut much faster while staying cool.

- Lower blade costs. While cold saw blades are more expensive than bandsaw blades, they have the advantage of being able to be resharpened around three dozen times and can make thousands of cuts before ever needing sharpening or replacing.

- Better accuracy. The stiff blade on an RMT cold saw provides a much tighter tolerance than bandsaw cutting, with an accuracy of +/- .004″.

- Easier mitering. RMT’s S-FAB CLD Series cold saws are designed for quick and efficient 45° miter cutting, making them easier to use than even a mitering head bandsaw.

- Faster production. RMT cold saws give an extremely clean, burr-free cut on parts, eliminating the need for painstaking finishing processes. One RMT customer switched a repeat order from a bandsaw to an RMT S-GENIUS HSC4 cold saw with a high-speed carbide blade and immediately noticed the difference: “We always cut a thousand pieces through our bandsaw and that job would typically take three and a half days and two bandsaw blades. This job on the RMT cold saw takes four hours now for a thousand pieces of 2-5/16″ cold rolled round 1045. Excellent productivity.” (Finn-Kool Testimonial)

The Revolution Machine Tools Advantage

Not all cold saws are created equal. RMT utilizes the highest standards of research and development in all the machines they offer, and their cold saws are no exception. Designed to perform beyond expectations, RMT cold saws are built with some of the very best in world-class controllers and electrical components—with the bonus of being replaceable by end users from local suppliers—and most offer a 4″ or greater round cutting capacity to accommodate standard stock sizes.

RMT’s S-SMART HSC and S-GENIUS HSC Series cold saws are designed to provide the most efficient stock and tube cutting possible in the metal processing industry today. They come standard with automatic hydraulic clamping, an adjustable blade stroke, variable cutting speeds, full CNC batch cutting, a high-end automatic lubrication system, a user-friendly control panel, and an enclosed cabinet. They are designed to be used with high-speed saw blades. The S-GENIUS cold saws also include a 20′ automatic material handling loading table for greater workflow control (available as an option with S-SMART saws).

Even RMT’s more affordable models in the S-FAB CLD Series have nothing “low end” about them. Their quality components and features include:

- A heavy-duty cast precision cutting head powered by an electrical motor that transfers the rotation from the motor to the saw via high grade worm and helical gears.

- Semi-automatic systems equipped with a front oil flow valve to allow for on-the-fly cutting speed adjustments.

- A miter cutting arm that precisely locks the cutting head in position.

- A high-performance dual hydro-pneumatic system that provides a smooth saw head descent for optimal cutting.

- A variable speed control allowing cuts to be optimized for different materials.

- A V-type self-centering heavy-duty split vice to stabilize the workpiece.

- A coolant tank and electric pump for blade lubrication and cooling.

- A semi-automatic foot pedal with extended cable for more operator efficiency.

The RMT Cold Saw Guarantee

Like all the equipment they offer, RMT cold saws come with Revolution Machine Tools’ commitment to excellence in customer support. Services provided to every customer, whether large or small, include:

- A pre-sale consultation verifying that the selected equipment is correct for the shop, its workload, and the planned jobs.

- A standard two-year warranty.

- Access to RMT’s factory-trained service technicians for consultations and in-person repairs and upgrades.

- A direct line to RMT’s inhouse parts specialists for tooling, replacement components, and high-grade consumables.

- The availability of customized maintenance contracts to keep cold saws and other machines in peak operating condition.

- A life-long partnership with RMT, guaranteeing superior customer support through the life cycle of each piece of equipment and far beyond.

If you need a new or upgraded cold saw or other metal fabrication machine, please give Revolution Machine Tools a call today and learn for yourself about the RMT Advantage.