Benefits of Buying RMT

From its founding by industry veterans, Revolution Machine Tools has continually sought to bring the highest quality workmanship and components into every metalworking machine they sell. With a well-deserved reputation in the field of hydraulic press brakes, RMT has brought that same expertise to bear in their offerings of traditional hydraulic presses as well.

Constructed with durable frames made from steel welded plate, RMT’s hydraulic presses have been designed to withstand the rigors put to them over a long service life, whether in a small automotive shop or a large, high-production factory setting. RMT has presses available for virtually any application, including bending, compacting, compressing, deep drawing, forming, hot forming, punching, stamping, straightening, and trimming.

Helping end users avoid downtime is extremely important to Revolution Machine Tools, so they reject the practice some machine makers follow of holding customers hostage with the necessity of purchasing proprietary replacement parts only from the factory. An examination of any hydraulic press from RMT will show that it is comprised of commonly available components of mostly German and American origin, including such well-known brands as Parker, Rexroth, Schneider, and Siemens. These premium parts are available for purchase from local supply houses around the world, plus they can be ordered quickly through RMT’s inhouse parts and tooling department, as can high grade consumables.

Another way RMT keeps customers’ downtime at a minimum is by maintaining a team of qualified, factory-trained technicians on staff in their service department. These expert tradesmen and women can diagnose and repair any machine issues onsite in record time, as well as offering immediate troubleshooting help over the phone. From installations to affordable preventative maintenance contracts, the service team at RMT helps customers keep their machines performing at highly efficient levels.

Other benefits of buying a hydraulic press—or any other fabrication machine, for that matter—from Revolution Machine Tools include:

- RMT’s machines are all backed by a strong warranty.

- RMT’s research and development team has created some of the most innovative, fast, durable, and accurate machines available in the industry today.

- RMT partners with leading manufacturers who build their designs to stringent specifications in state-of-the-art manufacturing facilities.

- RMT’s commitment to service begins with a site assessment consultation to determine if the machine in question will perform well in the customer’s manufacturing environment. Factors evaluated include rigging, positioning, installation, and scrap or waste disposal during the operation. RMT can also verify adequate electrical, pneumatic, or hydraulic requirements and examine surrounding equipment to assess if there might be any electro-magnetic or vibration interference issues.

Impressive Press Offerings from RMT

Revolution Machine Tools offers a fleet of hydraulic presses to meet most metal fabrication needs. The standard types of presses from RMT include:

- C-frame hydraulic presses, so named because their open sides give them a resemblance to a squarish letter “C.” Also known as gap-frame presses, C-frame presses take up minimal floor space and their open working area allows versatility in the positioning of workpieces and operator access. RMT’s current C-frame machines fall into two styles, the H-FAB C Series (six models, between 33 and 275-tons), and the touchscreen equipped H-SMART C Series (six models, up to 275-tons).

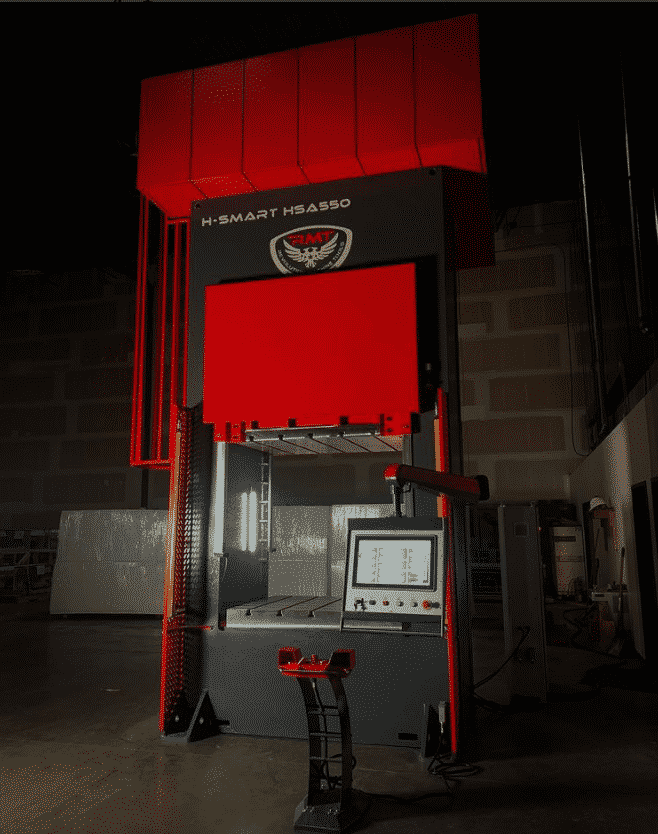

- H-type hydraulic presses, sometimes called H-frame presses, are named because their side walls and open front and back cause them to resemble the letter “H.” They are designed to handle heavier loads. Two series of H-type presses are currently available from RMT, the H-FAB HDT Series (five models, up to 330-tons), and the premier H-SMART HSA Series (11 models, up to a massive 3300-tons) featuring a touchscreen control, with custom sizes available.

- Column frame hydraulic presses, which are single-action presses with a hydraulic cylinder attached to the top plate. The plate moves downward, guided by four columns that intersect it at the corners. The columns keep the top plate continually parallel to the bolster plate regardless of the pressure that is applied. Equipped with a touchscreen control panel, there are currently seven models offered in RMT’s H-SMART HCFP Series, running from a modest 110-tons to an impressive 1100-tons, with custom bed sizes, open heights, and strokes available.

- Workshop type hydraulic presses, sometimes called universal hydraulic presses, are a simpler type of H-frame press designed with the small shop in mind. Current RMT workshop presses fall under two categories, the H-FAB H Series (11 models, between 65 and 550-tons), and the more robust H-FAB HBP Series (5 models, up to 330-tons). Custom sizes are available.

- Portal hydraulic presses, which are equipped with a framework that can move longitudinally along the worktable and a cylinder that moves left and right in the frame to give three axes of movement. They are used primarily as straightening presses with large or long workpieces. RMT’s current models in their H-FAB HPP Series include 110, 220, 330, and 440-ton models with worktables up to 59″ x 139″, but they can be ordered in any custom size from RMT up to an 1100-ton capacity.

RMT also offers specialty presses, available in custom capacities up to 3300-tons. They include deep drawing hydraulic presses, forming hydraulic presses, and hot plated hydraulic presses.

The Name You Trust

Revolution Machine Tools has built its reputation through exemplary customer service as much as by their quality machine offerings. By partnering with RMT for your next hydraulic press purchase, you are guaranteed the very best in support—and friendship—that begins before the ink dries and lasts long past the life of the machine. Call RMT today for a competitive quote and discover why so many customers consider them a trusted name in fabrication machine sales.