Stick That on Your Pipe and Rotate It

The process of welding goes back a few thousand years before pipe rotators to the beginning of humankind learning to forge metal, while the notion of fixturing a workpiece that is to be welded dates to the time when the earliest blacksmiths started using anvils and tongs. A much more recent innovation is the technology that allows a workpiece to not only be secured, but also rotated or otherwise moved to aid a welder more efficiently in his or her work. Such machines are generally referred to as welding positioning equipment, and come in several styles, including:

- Classic welding positioners. These are rotary turntables, often featuring tilting and/or lifting functionality. They allow a welder to remain in position and focused on the job while rotating a workpiece to bring up the next section that needs welding.

- Welding manipulators. These are large machines with an arm or boom to which a welding tool is attached. They are used with big structural projects that are too large to move, so they bring the welding torch to the locations on them that need welding.

- Traditional pipe rotators. These machines—the larger versions of which are sometimes called tank turning rolls—feature a powered set of two or more rollers that support one end of a pipe or tank and a non-powered set of idler rollers that support the other end. The powered set rotates the pipe for welding while the idler set allows the rotation of the other end.

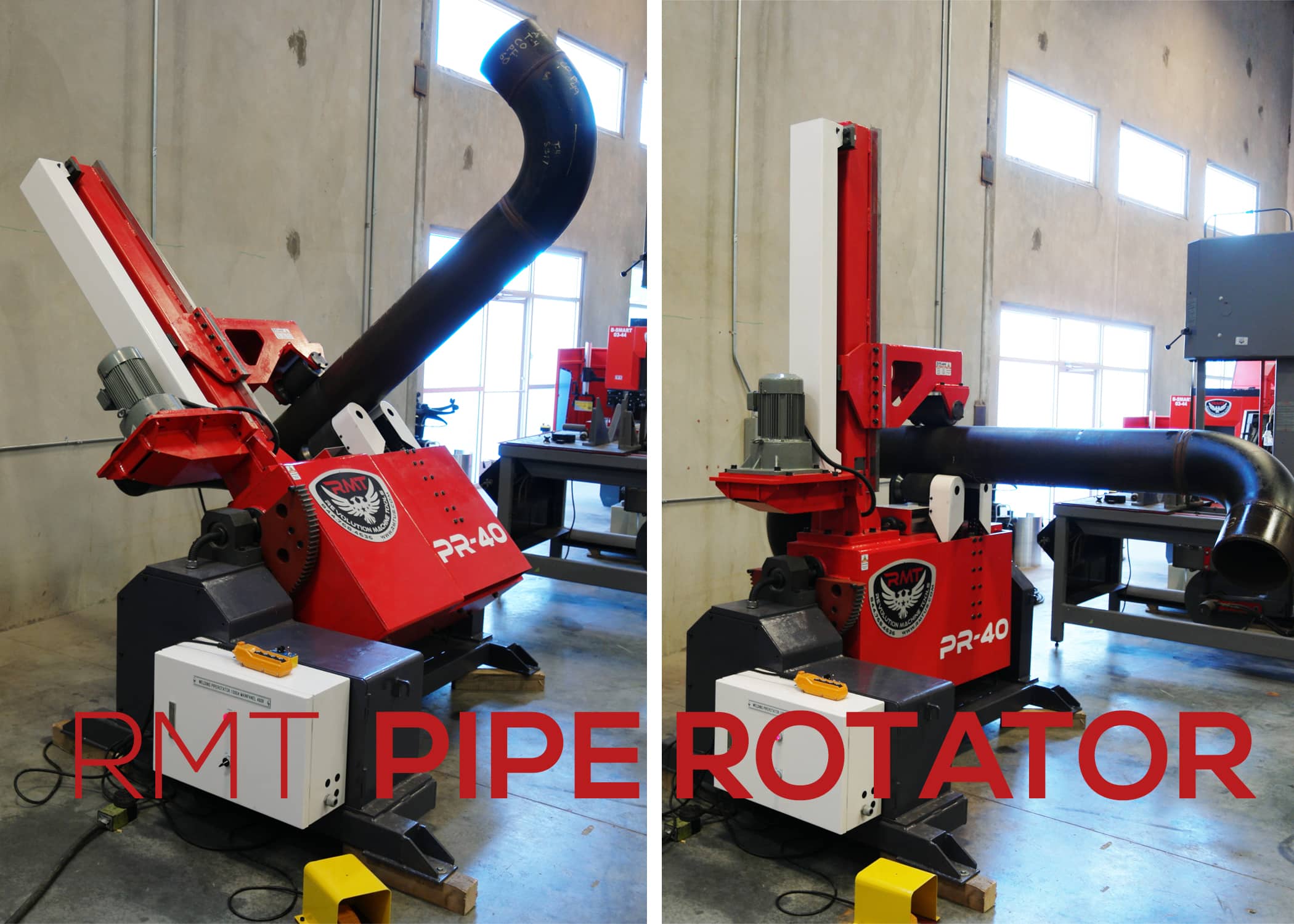

The pipe rotators from Revolution Machine Tools go well beyond the traditional versions in that they are machines that clamp the pipe to rotate it, usually not needing any additional support equipment. They also hold the workpiece well above the ground, allowing pipes with elbows or large flanges at one or both ends to be worked on, something not possible with low rotators that support workpieces just above the ground. In addition, RMT’s rotators go a step further and tilt up to 45° in either direction, allowing the operator to position the pipe for easier welding.

Benefits of RMT Pipe Rotators

The tiltable pipe rotators from Revolution Machine Tools have a significant advantage over traditional rotators due to their unique clamping roller system. This feature gives welders far greater control of the positioning and rotation of the pipe for fit-up and welding. Other benefits of RMT rotators include:

- Accuracy. Like all the machines they offer, RMT pipe rotators are designed by a world-class R&D department and utilize cutting-edge technologies for unsurpassed accuracy. Sporting powerful hydraulics, RMT’s rotators provide smooth operation regardless of the size of the pipe, giving extremely precise movement control up to .001″ accuracy.

- Ergonomics. RMT pipe rotators have both positive and negative tilt movement, up to 45° in either direction. This allows the welder to put the weld where it is easiest to access, providing perfect ergonomic welding positions.

- Safety. Revolution Machine Tools understands that a shop’s greatest assets are not its equipment, but its people. That is why all RMT machines come with multiple safety features that often exceed industry standards. The main frame of each RMT pipe rotator was designed to allow for the safe movement of employees around the machine while it’s in operation. The variable speed adjustment provides the operator with precise control of rotation to reduce the risk of accident. Wired remote controls, such as a pendant to select movement and a foot pedal, keep the operator at a safe distance during operation. In addition, RMT offers a wireless foot pedal as an option, increasing operator mobility and eliminating a potential trip hazard.

- Sturdiness. RMT pipe rotators perform reliably year after year, due in large part to their rigid, mono-block frames which are made from mill-certified, high-yield steel. Built to last, the frames come with a 10-year warranty.

- Versatility. RMT pipe rotators provide an impressive capacity range for a single machine. Each model’s size capacities are flexible enough to support diameters at least ten times larger than their smallest size. Their weight and length capacities can be increased with the use of external support stands. The clamping system and operational height of each rotator allows them to easily accommodate pipes with deep bends, large flanges, elbows, tee pieces, or other offset loads. A wide range of pipes can be clamped, and the size of the pipe doesn’t affect the infinitely variable rotation speed due to its separate drive unit. Optional exchangeable drive rolls are available to accommodate different material types, and RMT can custom engineer a pipe rotator to fit a project’s specific requirements when needed.

Available Models of RMT Pipe Rotators

The line of tiltable pipe rotators from Revolution Machine Tools are sized to serve a wide range of needs, being able to handle everything from 1″ to 40″ diameter pipe. All models have a tilting angle of up to 45° both forward and back.

The currently available models in RMT’s W-TRP series include:

- RMT W-TRP 12 with a pipe capacity of 1″ to 12″ and a weight capacity of 2200 lbs. It features a 0.5 HP turning motor and 1 HP tilting and lifting motors. Its dimensions are 54″ L x 56″ W x 65″ H.

- RMT W-TRP 24 with a pipe capacity of 2″ to 24″ and a weight capacity of 4400 lbs. It features a 2 HP turning motor and 1 HP tilting and lifting motors. Its dimensions are 69″ L x 60″ W x 83″ H.

- RMT W-TRP 40 with a pipe capacity of 4″ to 40″ and a weight capacity of 6800 lbs. Its turning, tilting, and lifting motors are each 2 HP. Its dimensions are 69″ L x 60″ W x 95″ H.

The weight capacity of each machine increases when used with stands to support the weight of the workpiece outside of the machine.

The Revolution Machine Tools Advantage

For all your pipe fabrication needs, be sure to look to Revolution Machine Tools. RMT has an advantage over many machinery suppliers in that they can offer equipment for processing a workpiece throughout different stages of a job.

For example, a shop equipped with RMT machinery could use a C-SMART series hydraulic swing beam shear or a C-GENIUS series hydraulic variable rake shear to cut a plate of steel down to the needed size. They could then use a PBV-FAB series plate beveler to bevel the edges of the plate to prepare them for eventual welding. An R-SMART, R-GIANT, or R-HYBRID series hydraulic plate roll could then be utilized to bend the plate into a pipe or tank, followed by positioning on a W-TRP series pipe rotator during the welding process. In addition, if the shop has purchased one of the dozen different models of Pipe Spool Masters offered by RMT, they could further process the ends of the finished pipe, performing such functions as facing, threading, beveling, grooving, or more.

From press brakes to fiber lasers, angle rolls, and band saws, Revolution Machine Tools provides metal fabricators across the country with the tools they need to get the job done—and done right every time. Call RMT for a consultation on the equipment you need for your next job, whether large or small.