Not a Passing Grade

“What’s this?” the boss asked, indicating the pallet of sheet metal freshly delivered to the shop.

“That’s the steel you had me pick up from the service center,” replied the eager employee who was just starting his third week on the job.

“Did you hand them the note I gave you?” the boss then asked.

“No, I just said we needed more steel like I had picked up the last two times and told them the size and quantity and they cut it and got it right out for me,” came the reply.

“Well, it is the right size and the right quantity,” the boss agreed, “and it is steel. The problem is, it’s the wrong steel.”

The young man just stared at him for a moment, before asking weakly, “There’s more than one kind?”

His eyes widened when his boss replied, “Yes, there’s well over three thousand grades of steel. While we do use mild steel like this for a lot of our work, the four-digit number I wrote across the top of the note following the letters ‘SAE’ indicated the grade of steel we needed for this job.”

As the kid started to stammer an apology, the boss cut in. “Don’t worry about it this time. We’ll be able to use it for something down the road. Just go back and give them the note and tell them we also need that grade of steel too.”

Watching the young man rush off, the boss decided that he needed to do a little better job explaining the what’s and why’s of metalworking to new hires, just to avoid any more second-guessing like this in the future.

Properties and Percentages

Unlike iron—which is its main component—steel isn’t an element that can be found in nature. Steel is an alloy, which means it is a combination of different chemical elements including at least one metal. While other types of chemical compounds can include metals, alloys are unique in that they have metallic properties. The added alloying elements can enhance certain characteristics of the main metal, or serve other functions, such as reducing the cost of the alloy compared to that of the pure metal.

Properties of metals that can be affected by alloying other elements with them include, but aren’t limited to:

- Corrosion Resistance

- Density

- Ductility

- Elasticity

- Electrical Conductivity and Resistivity

- Elongation

- Hardness

- Machinability

- Magnetism

- Melting Point

- Tensile Strength

- Thermal Conductivity

- Thermal Expansion

- Yield Strength

The percentages of the different alloying elements are what distinguishes one type or grade of steel from another. For example, a sample of low carbon steel (or “mild steel” as it’s usually called) can have up to .03% of carbon in it. Increasing the amount of carbon to .04% or .05% is enough to change its properties and cause it to be classified as a medium carbon steel. Double the .03% to .06% and then it is considered a high carbon steel. Mild steel is easy to fabricate and used for a wide variety of purposes, while high carbon steel is much more difficult to process but is used when a harder steel is required, such as in fabricating a spring. Medium carbon steel, falling midway between ease of fabrication and hardness of material, becomes an ideal choice for the manufacture of such things as gears, crankshafts, and railway tracks. The amazing thing is that all this diversity of properties is found in a range of just one-third of one percent of the total content of the metal.

The various alloying elements are added to iron in different percentages to create distinctive properties needed for specific applications. Over the years, a variety of grading systems have been established to distinguish the many types of steel and their properties.

Men (and Women) of Steel

In the decade leading up to America’s entry into World War II, two U.S. firms began to classify all the different types of steel for the reference of factories and fabricators. The Society of Automotive Engineers, known for its ratings of automobile horsepower, and the American Iron and Steel Institute, an association of steel producers, worked on their own systems for assigning numbered grades to different alloys of steel. Since the systems were similar, they eventually united their efforts into the joint AISI/SAE system that was considered the standard in the United States for decades.

Before the end of the 20th century, the American Iron and Steel Institute turned over control of the system to the Society of Automotive Engineers and the current SAE grading system was born, using the previously established four-digit number classification, but dropping AISI’s letter prefix that was used to denote the steelmaking process. While other American grading systems have been developed over the years, the SAE system is widely recognized today throughout North America as the standard for grading alloy steel.

It should be noted that different countries around the world use different grading standards, such as the JIS and NK standards of Japan, the GB standard of China, and the GOST standard of Russia. Various European nations have their own standards, such as DIN in Germany and UNI in Italy, but a movement is underway to withdraw these in favor of the EN (“European Norm”) system, designed to facilitate trade throughout the continent.

Setting the Standard

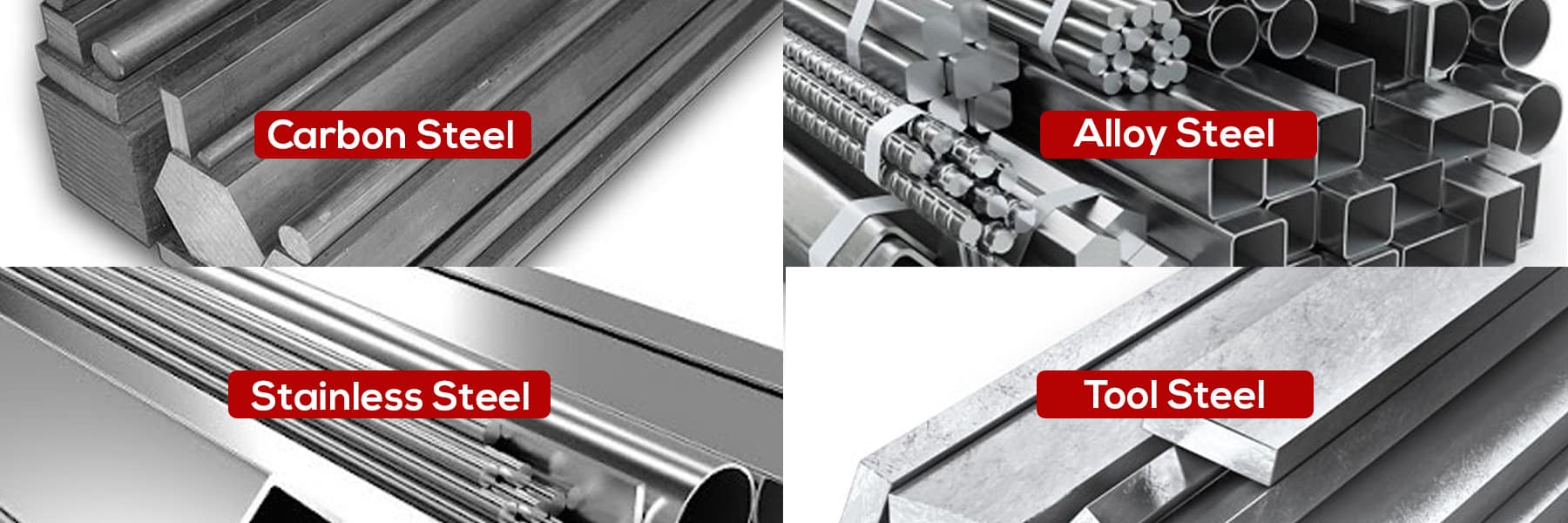

The Society of Automotive Engineers, now known as SAE International, has established different sets of standards for grading the various kinds of steel. The four basic types of steel are:

- Carbon steel (subdivided as low, medium, and high carbon)

- Alloy steel (containing other metals and elements besides iron and carbon)

- Stainless steel (subdivided by crystalline structure as austenitic, ferritic, martensitic, duplex, and precipitation hardening)

- Tool steel (subdivided according to its properties as water-hardening, cold-work, shock-resisting, high-speed, hot-work, and special purpose)

The common four-digit SAE designations represent grades of carbon and alloy steels, while a separate three-digit SAE number has been assigned to the different grades of stainless steel. Tool steel consists of any grade of carbon or alloy steel that is particularly hard, resistant to abrasion and deformation, and can keep a cutting edge under high temperatures. To differentiate them from other steels, a hybrid letter-number system is used to describe tool steel grades.

Carbon Steel and Alloy Steel Grades

In the carbon/alloy grading system, the first digit represents the main alloying elements while the second represents the top-grade elements that are added. The third and fourth digits together indicate the amount of carbon in the alloy. Looking at just the first digit, the grades of steel under this designation break down as follows:

- The 1000 series are carbon steels.

- The 2000 series are nickel steels.

- The 3000 series are nickel-chromium steels.

- The 4000 series are molybdenum steels.

- The 5000 series are chromium steels.

- The 6000 series are chromium-vanadium steels.

- The 7000 series are tungsten steels.

- The 8000 series are nickel-chromium-molybdenum steels.

- The 9000 series are silicon-manganese steels.

Stainless Steel Grades

Like the four-digit system, the first number in SAE’s stainless steel grading system also designates the primary alloy. The grades of stainless steel break down as follows:

- The 100 series are general-purpose austenitic alloys, meaning their main alloying material is austenite, making them exceptionally resistant to corrosion.

- The 200 series are austenitic chromium-nickel-manganese alloys.

- The 300 series are austenitic chromium-nickel alloys.

- The 400 series are chromium alloys that are ferritic (meaning magnetic) or martensitic (containing martensite, which is formed by rapid cooling austenite to make it extremely hard).

- The 500 series are chromium alloys that are extremely heat-resistant due to exceptionally high levels of chromium.

- The 600 series designations were used for proprietary alloys that are austenitic and/or martensitic but are generally no longer assigned SAE grades. Precipitation hardening stainless steels are found for the most part in the 600 series.

While there currently aren’t any grades of stainless steels assigned to the 700 or 800 series, the 900 series is used to designate austenitic chromium-molybdenum alloys that are like some found in the 300 series but have greater corrosion resistance due to higher chromium and molybdenum content. A separate grading system exists for duplex stainless steel, which is a composite of austenitic and ferritic steels.

Tool Steel Grades

Each grade of tool steel features a letter followed by a one or two-digit number. The initial letters represent the class and attributes of each type. The grades of tool steel break down as follows:

- The A series are cold worked steels that are air hardening.

- The D series are cold worked steels that are high carbon and high chromium.

- The F series are special purpose steels that are carbon and tungsten based.

- The H series are hot worked steels. H1 to H19 are chromium based, H20 to H39 are tungsten based, and H40 to H59 are molybdenum based.

- The L series are special purpose steels that are low alloy.

- The M series are high speed steels that are molybdenum based.

- The O series are cold worked steels that are oil hardening.

- The P series are steels that are used for making plastic molds.

- The S series are shock resisting steels.

- The T series are high speed steels that are tungsten based.

- The W series are water hardening steels.

Getting the Most out of Your Steel

To get the best steel for your projects, find a trusted steel service center or metal supplier. To get the most out of your steel, call Revolution Machine Tools today to receive an evaluation of your shop with recommendations of upgrades and other changes you can make to better process your upcoming jobs.

RMT has been making a name for itself over the last several years as a provider of top-of-the-line metalworking equipment designed with cutting edge technology and featuring state-of-the-art components for unparalleled performance in the shaping of steel of every grade. If you have metal of any type that requires cutting, bending, punching, rolling, or other fabrication work, Revolution Machine Tools can offer the very best equipment available on the market to fulfil your needs.